Features of the Cyclone 600 Industrial Upcut Saw:

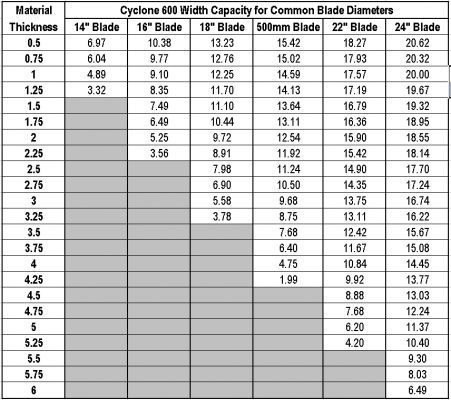

- Cuts materials up to 1″ x 20″ or 6″ x 6″.

- 16″ fence and table surface on both sides of the upcut saw blade.

- Patented Safe T Crowders improve safety.

- Electronic braking.

- Saw blade access panel bolt kills power & air when loosened.

- Direct drive — NO BELTS!

- Leveling pads are included and the design allows for easy floor anchoring.

- Improved motor mount design with substantial steel construction and linear bearings

- 7.5 horsepower motor

Using the Cyclone 600 Industrial Upcut Saw:

On most upcut saws, it’s easy to cycle the saw without powering up the motor. This allows operators to run the unpowered blade into a piece of stock accidentally which can have devastating effects on the blade and spindle. The Cyclone 600 is designed so that it won’t cycle without motor power.

On the work surface, the patented RazorGage Safe T Crowders improve safety. The upcut saw operator can crowd stock against the fence while safely cycling the saw via thumb-operated 2-hand anti-tie down buttons. Other upcut saws offer traditional 2-hand anti-tie-down buttons mounted on the front of the saw. Since the operator’s hands are not available to crowd the material to the fence, pneumatic clamps must be added to both the left and right sides of the blade. Both clamps must fire simultaneously creating a dangerous situation when one or the other of the clamps lands half on the part.

On a Cyclone 600 saw, the operator still manually crowds the material to the fence but via the Safe T Crowder handles. This enables him to crowd on the left, right, or both sides as he sees fit but still keeping his hands away from the blade.

There is a 16” fence and table surface on both sides of the blade, allowing you to place your material on either side, depending on your needs. This upcut saw can be equipped with a low fence or high fence.

The Top Clamp travels on linear bearings and is driven by its own cylinder so you can adjust clamping speed and pressure independently. Quickly adjust the top clamp height with flip stops.

The Cyclone 600 is available with custom modifications to fit your unique business needs and goals. Reach out to our team to learn about custom modifications.

Specifications:

Motor: | 7.5 hp (enclosed fan cooled) available in 208-230-460Vac 3-phase |

Power Source: | 230 VAC, 3 phase, 30 Amps 460 VAC, 3 phase, 20 Amps |

Exhaust Port: | Two 4″ diameter (102 mm) requiring 600 cfm (17 m3 ) minimum for dry light materials. Other materials may need higher velocity/pressure |

Compressed Air: | Requires 80 psi (5.5 bar) at 5 cfm (0.14 m3) air filtered to 2.5 microns (oil and moisture free). Use industrial air dryer, rated for cfm (CM) flow. No lubrication is required for air components. Air must be lubricant-free. |

Motor RPM: | Adjustable up to 3450 |

Arbor: | 1.000 inch |

500 mm Blade for Wood: | 500mm x 120T x 1” Bore x 23°ATB/5°ASF x Plate .128 x Kerf .172 |

500mm Blade for Aluminum: | O/D 500mm or 19.68” x Kerf 3.5mm or .137” x Plate 3.0mm or .118” x Bore 25.4mm or 1.00” x Teeth 140 D Type Tip Grade Sash Pro X Expansion Slots Five. |

24″ Blade for Wood: | 24″ Dia. x 144T x 1″ Bore x 23°ATB/5°ASF x Hook 22° Plate.138 x Kerf.186 |

24″ Blade for Aluminum: | 24″ Dia. x 200 Teeth x 1″ Bore x TCG x Hook 6° Plate.138 x Kerf.174 |

Shipping Weight: | 975 lb |

[col span=”1/2″ ]

[/col]

[featured_box title=”” pos=”left” img=”https://360degreemachinery.com/wp-content/uploads/2021/03/Built-in-The-USA.png” img_width=”120″ link=””]

The RazorGage Product Line is manufactured in Ames, Iowa, USA, by Technical Services, Incorporated.

Technical Services, Inc. has been developing custom specialized machinery for more than 40 years that speeds and improves the manufacture of automotive components, recreational vehicles, appliances, windows, doors, cabinets, water testing products, and more. The RazorGage product line draws from those decades of widely varying experiences to bring to market the finest positioning system in its price range available today.

[/featured_box]