* “Request A Quote” to contact us for more information and available upgrade options!

Northtech NT DC20-212 2 HP Dust Collector Single-Phase

Northtech NT DC20-212 2 HP Dust Collector Single-Phase  Northtech NT CutMate 3200D Series Double Knife Veneer Guillotine

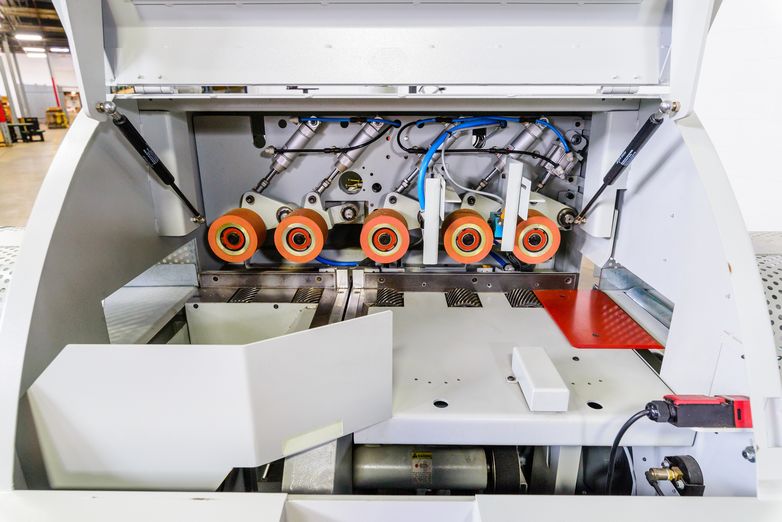

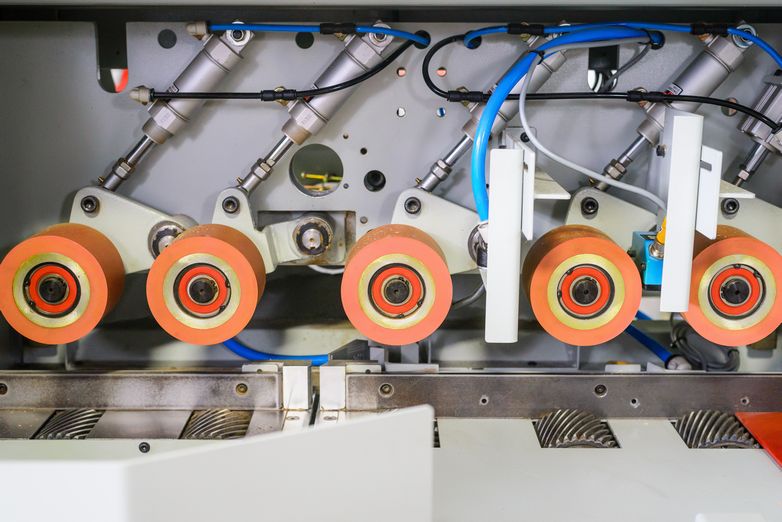

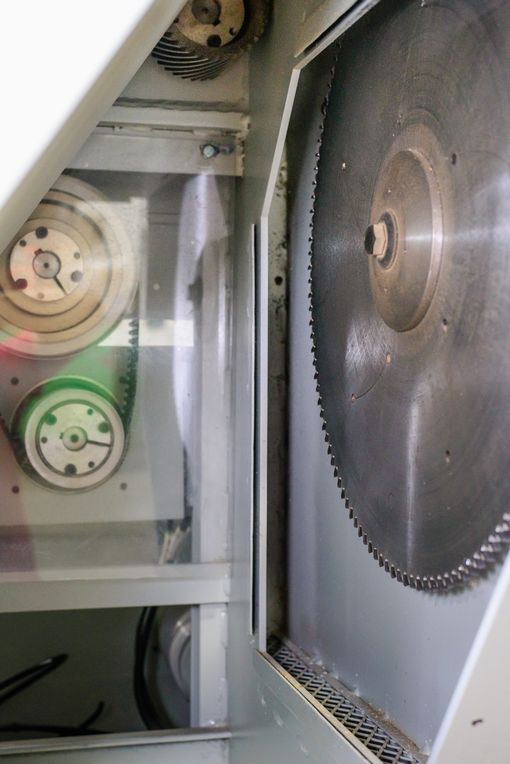

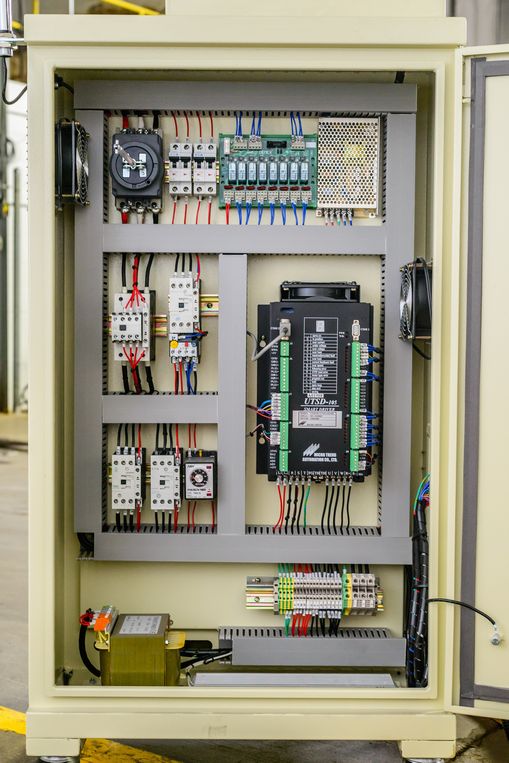

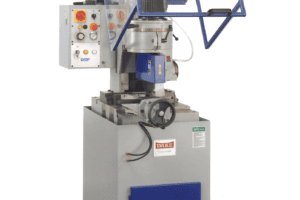

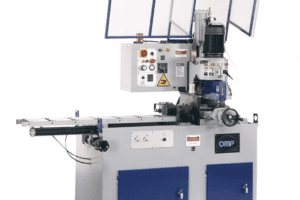

Northtech NT CutMate 3200D Series Double Knife Veneer Guillotine Northtech NT ADS-100A Automatic Crayon Mark & Defect Saw

With feed speeds up to 240 FPM and up to 80 highly accurate cuts per minute, the NT ADS-100A processes up to 3-5 times more material than manual cut-off saws. The precision computer-controlled servo consistently positions the cut line within 1 mm of the saw blade, eliminating mistakes and minimizing waste to increase your yield by 3-5% (average). An intuitive graphical user interface (with touchscreen control) enables a shorter learning curve and simplifies operation.

User-selectable cutting modes include:

- Fixed cutting length mode.

- Sequential cutting mode:

- Program up to 10 sets of cutting sizes to memory (for sequential cutting mode only).

- Crayon mark cutting with double-end trimming.

- Crayon mark cutting with fixed-length cutting mode:

- Simultaneously cuts out defects, cuts to a fixed length, and cuts to finger-jointing size without loss.