RazorOptimal Pocket Hole Saw Features:

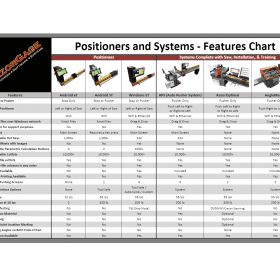

- Windows Tower PC operation on a large, color touch-screen monitor.

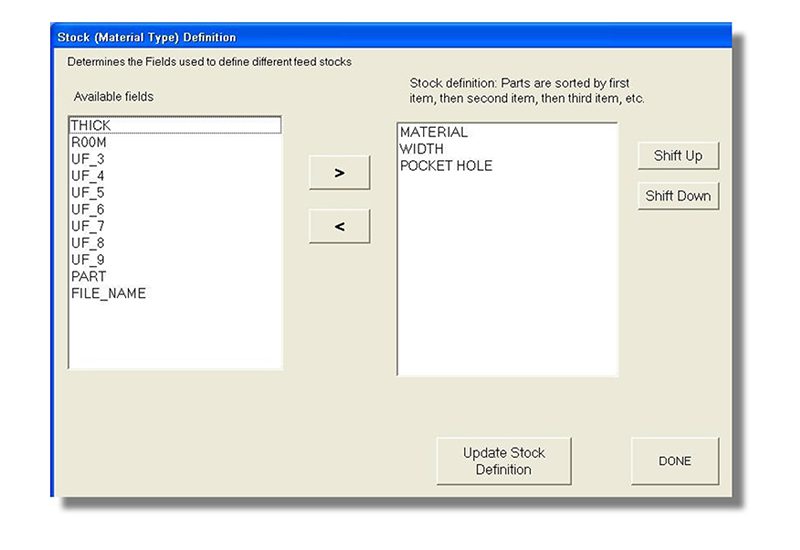

- Easy to use software with room to store thousands of cutlists. Optimize and sort cutlists into thousands of groups according to multiple criteria.

- Optimized defect detection technology maximizes usable material between crayon marked defects

- Automatic top, left, and right intelligent clamping

- Paper label printing or printing directly on the material

- Print in decimal or fraction format.

- Part length accuracy varies with application but +/-.005″ is possible

- Optional RazArray sorting light grid can be added to further improve operational efficiencies and reduce mistakes

- Direct drive 18” blade slides on Hiwin Linear bearings for maximum rigidity.

Using the RazorOptimal Programmable Pocket Hole Machine:

First import custom cutlists or use the RazorOptimal software to create cut settings. Once the appropriate cutlist is selected, the operator marks the defects with crayon and the automated pocket hole saw does the rest! The saw system scans the material for defects and automatically optimizes all cuts to fit within defect-free areas of your material, maximizing the usable area. Then, the pocket hole saw system automatically advances, cuts lineal stock, drills pocket holes, scribes face frame layout lines, and prints the part information directly on your material.

Two days of installation and training are included with the purchase of all RazorOptimals (US or Canada only).

Pocket Hole Drilling and Face Frame Scribing With the RazorOptimal:

Two main features set this RazorOptimal saw system apart from the standard RazorOptimal unit: pocket hole drilling and face frame layout scribing.

The RazorOptimal with the pocket hole option is equipped with a 3-spindle pocket hole drill gear drive spindle cartridge located to the left and right of the main saw blade. Drill up to three pocket holes at a time, depending on your needs. Unlike other standalone pocket hole drilling machines, this feature is built right into the main saw system, maximizing efficiency and saving you the cost of purchasing additional equipment.

Face frame layout scribing is another feature unique to the RazorOptimal with pocket hole option. This optimizing pocket hole saw system can produce enough face frame parts for 40 face frames per hour.

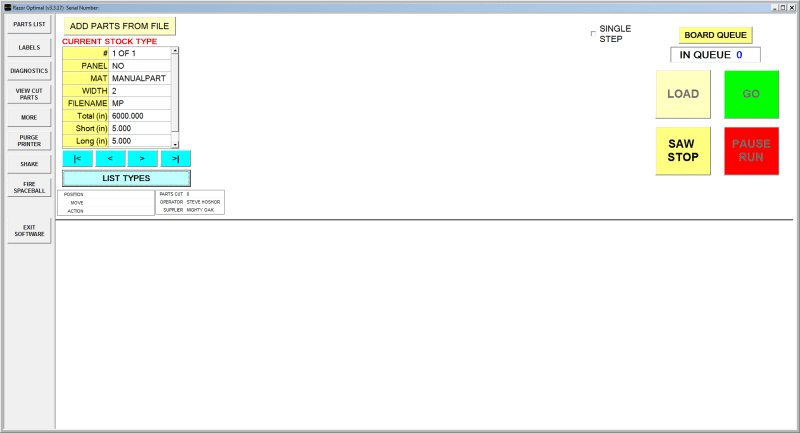

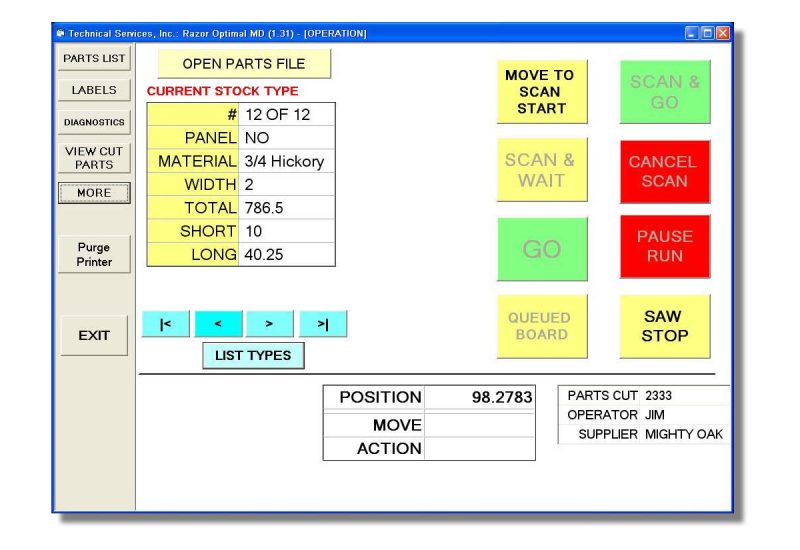

Optimizing Pocket Hole Saw Software:

RazorGage’s industry-leading software is powered by Microsoft Windows, so networking and file-sharing is seamless between the RazorOptimal software and other PCs in your office, home, or shop.

The RazorGage programmable pocket hole machine software is based on a rapid development platform, and we are constantly evolving and improving it to meet customers’ needs. It is also customizable and can be adapted to suit a variety of applications and projects.

[row ]

[col span=”1/2″ ]

Specifications:

- Power Requirement – 120 VAC at 10A

- Pocket hole Saw: 230 VAC 3φ 40A OR 460 VAC 3φ 30A

- Motor: 7.5 HP

- Part Accuracy: +/- 0.008” or better

- Up to 200 lbs Push Force

- 22” Touch Screen

- Network Port AND Wi-Fi

- USB Ports

- Two 4” Dust Ports min 1200 CFM

- 60 psi min compressed air pressure

- Minimum Defect Scanning Width: 1.5”

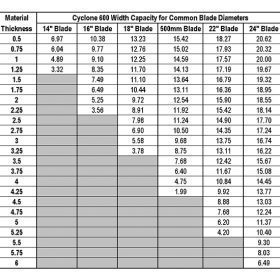

- Max Capacity 1.5” x 12”

[/col]

[col span=”1/2″ ]

[/col]

[/row]

[featured_box title=”” pos=”left” img=”https://360degreemachinery.com/wp-content/uploads/2021/03/Built-in-The-USA.png” img_width=”120″ link=””]

The RazorGage Product Line is manufactured in Ames, Iowa, USA, by Technical Services, Incorporated.

For more than 40 years, Technical Services, Inc. has been developing custom specialized machinery that speeds and improves the manufacture of automotive components, recreational vehicles, appliances, windows, doors, cabinets, water testing products, and more. The RazorGage product line draws from those decades of widely varying experiences to bring to market the finest positioning system in its price range available today.

[/featured_box]