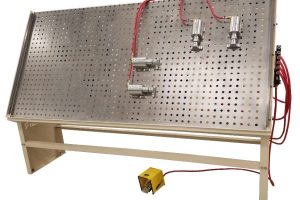

Features & Benefits

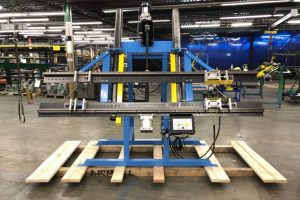

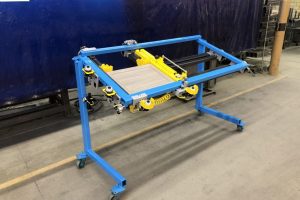

- Open-Back Design: Facilitates easy access and increased flexibility during assembly.

- Robust Construction: Ensures long-lasting durability and reliable performance.

- Precision Alignment: Guarantees accurate and consistent frame assembly.

- Easy Operation: User-friendly controls for efficient workflow.

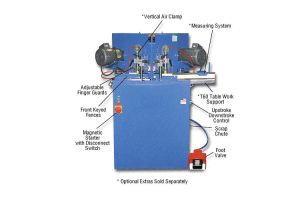

Streamlined Workflow for Maximum Efficiency

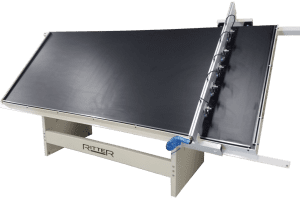

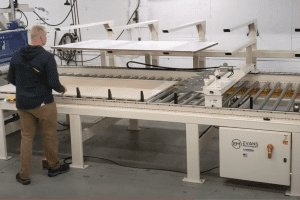

The Ritter R210E/A/O Open-Back Face Frame Assembly Table is more than just a piece of equipment; it’s a game-changer for your woodworking operations. Its open-back design allows for effortless access, making it easier to position and maneuver materials. This feature not only speeds up the assembly process but also reduces strain on your workforce, contributing to a safer and more productive work environment.

Built to Last

Investing in the Ritter face frame easel means investing in a machine that stands the test of time. Constructed with heavy-duty materials, this assembly table is designed to handle rigorous daily use without compromising performance. Its durability ensures that you won’t face frequent downtimes or costly repairs, leading to more consistent production schedules and lower maintenance costs.

Unmatched Precision

Precision is paramount in woodworking, and the R210E/A/O excels in this area. The table’s precision alignment features ensure that each face frame you assemble is perfectly aligned and ready for final finishing. This accuracy minimizes material waste and reduces the need for rework, ultimately saving you time and resources.

Enhancing Your Team’s Productivity

Ease of use is a significant advantage of the Ritter R210E/A/O. With intuitive controls and a user-friendly design, your team can quickly learn to operate the machine, reducing the learning curve and enhancing overall productivity. The streamlined operation means that your skilled workers can focus more on craftsmanship and less on troubleshooting and adjustments.

Boosting Your Bottom Line

By integrating the Ritter R210E/A/O into your production line, you can expect a noticeable improvement in your workflow efficiency and product quality. Notably, the elimination of dowel boring, insertion, clamping time, and joint misalignment can lead to up to a 50% reduction in frame production time. This efficiency translates directly to increased output and profitability, making this assembly table a valuable investment for any woodworking business.