Click here to Download Minimax SI X and Elite S range PDF Brochure

ADVANTAGE

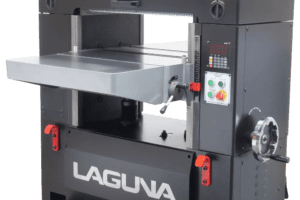

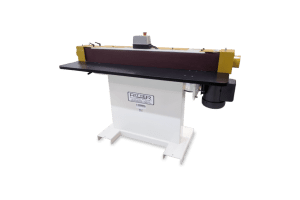

Perfect finish

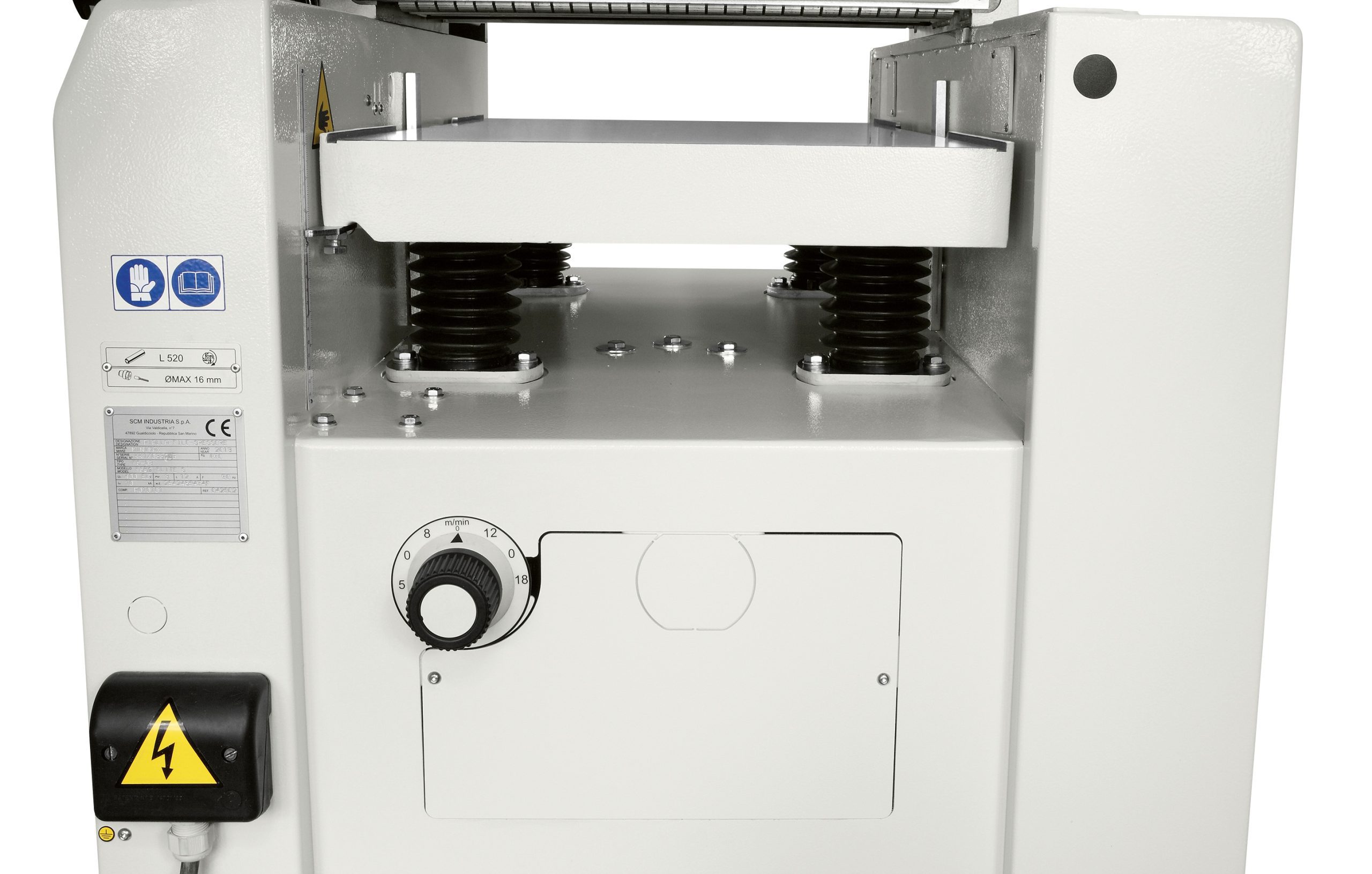

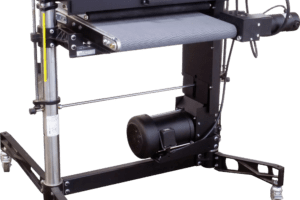

An optimal planing with minimal effort, thanks to the 95 mm diameter cutter block and 4 knives. For an impeccable finish the pressure of the thicknesser feed rollers can be adjusted according to the type of wood machined. The roller infeed has a helicoidal profile to guarantee firm and constant work piece feed, while the outfeed roller in sandblasted steel maintains the perfect post-processing finishing.

Stability over time

For a maximum long lasting stability the cast iron thicknessing table lifts on 4 spindles with trapezoidal threads dust protected.

High rigidity

High rigid fence with a smooth movement thanks to the central locking on round bar.

“Xylent” spiral knife cutter block with 3 series of knives

The 3 spiral knives give an exceptional finish. Reduced noise during machining provides a more comfortable working environment. It also improves the dust extraction due to the production of very small chips. Each cutter has 4 tips which can be rotated into the cutting position when worn. Therefore increasing the production life of the cutter block before knives require replacement.

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Rubber-coated feed roller on thicknesser outfeed

- “Xylent” spiralknife cutterblock with 3 series of knives

- 10 spare inserts kit (15x15x2,5) for Xylent spindle

- Additional overturning fence for processing of thin workpieces

- Powered vertical movement of thicknessing table with digital display

- Wheels for machine movement

- Single-phase motor 3,6kW (4,8hp) 60Hz

| TECHNICAL FEATURES | ||

| Useful working width | [mm] | 410 (16.12”) |

| Cutter block diameter | [mm] | 95 (3.75” |

| Max. stock removal | [mm] | 5 (0.19”) |

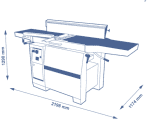

| Surfacing tables total length | [mm] | 2200 (86.62”) |

| Thicknessing table dimensions | [mm] | 410 x 775 (16.12” x 30.5”) |

| Thicknesser feed speed | [m/min] | 6/12 (0.25”/0.5”) |

| Min.÷max. thicknesser working height | [mm] | 3 ÷ 240 (0.12”÷9.44”) |

| Min. thicknesser working length | [mm] | 180 (7.06”) |

| Other technical features: | ||

| Single-phase motor | 3,6kW (4,8hp) 60Hz | |

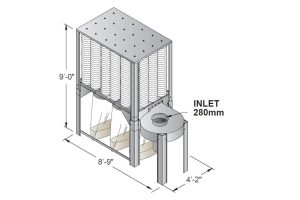

| Exhaust hood diameter | [mm] | 120 (4.75”) |

| INSTALLATION REQUIREMENTS | ||

| Section of electrical cable | [mm2] | 6 |

| Power absorption | [A] | 20 |

| Voltage – frequency | 230V – 60 HZ |