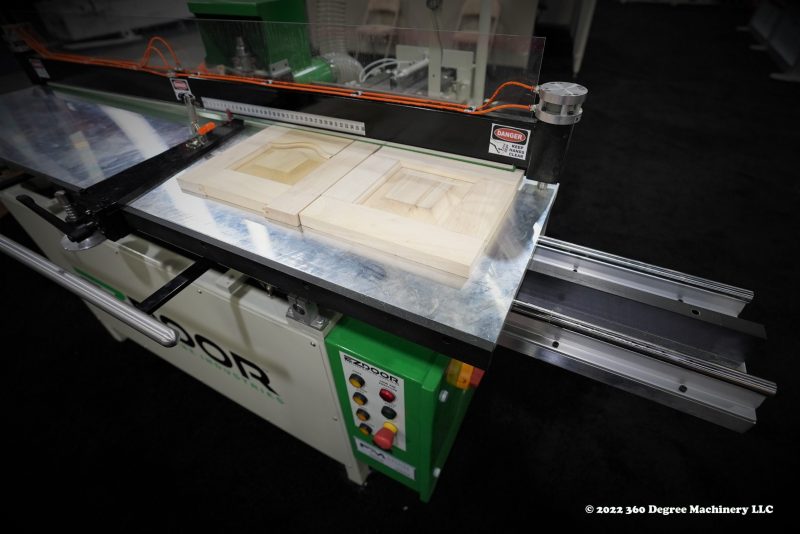

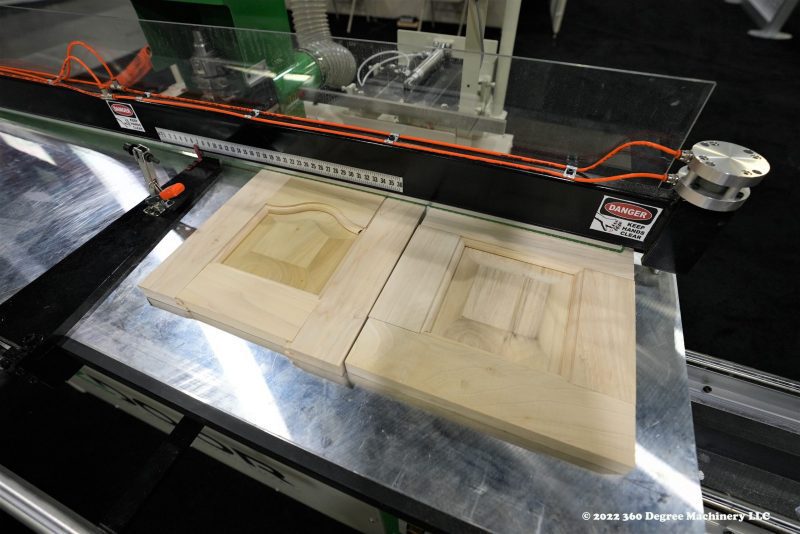

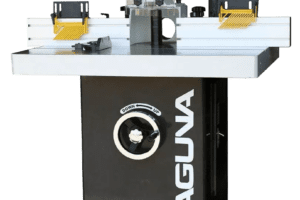

Cabinet shop owners swear by this machine. It’s fast…..safe…..and easy to learn and operate.

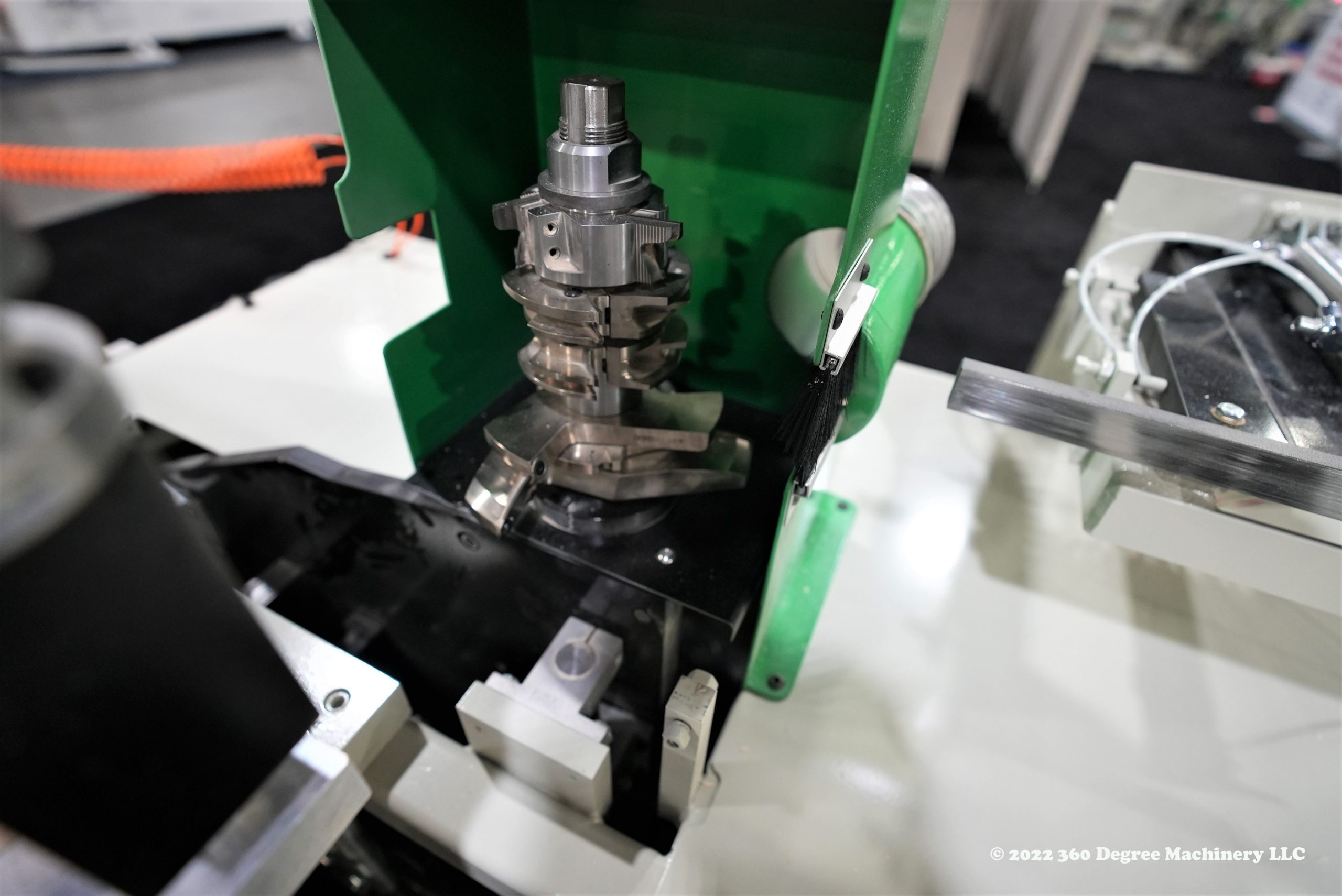

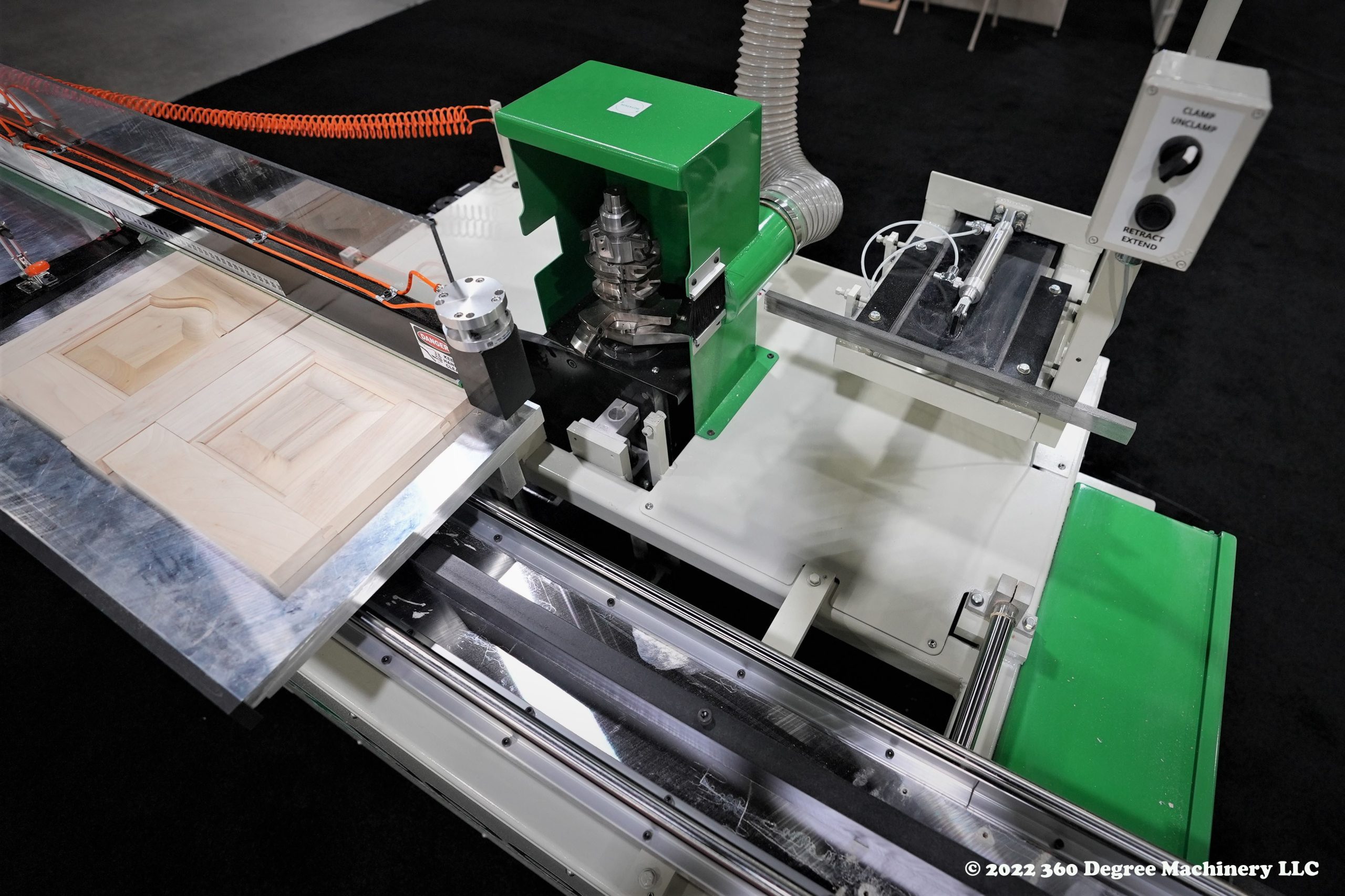

Like all Fletcher machines, this thing is built like a beast. If you want cheap and flimsy, you’re barking up the wrong flowering dogwood. The design key is the button-operated four-position spindle that, on command, efficiently positions the insert blades to cut the different shapes needed to create a door.

EZ-Door Is The Only 5-piece Door Machine In The Industry With These Features:

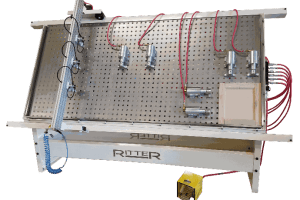

- Heavy-duty linear bearing vertical slide rails allow for industry-best smooth and secure operation of the clamp fence – safely hold down parts during cutting.

- Eliminate chatter. Minimize waste.

- Cutter height adjustments are push-button controlled and self-cleaning at each stop.

- Reduce maintenance. Increase accuracy.

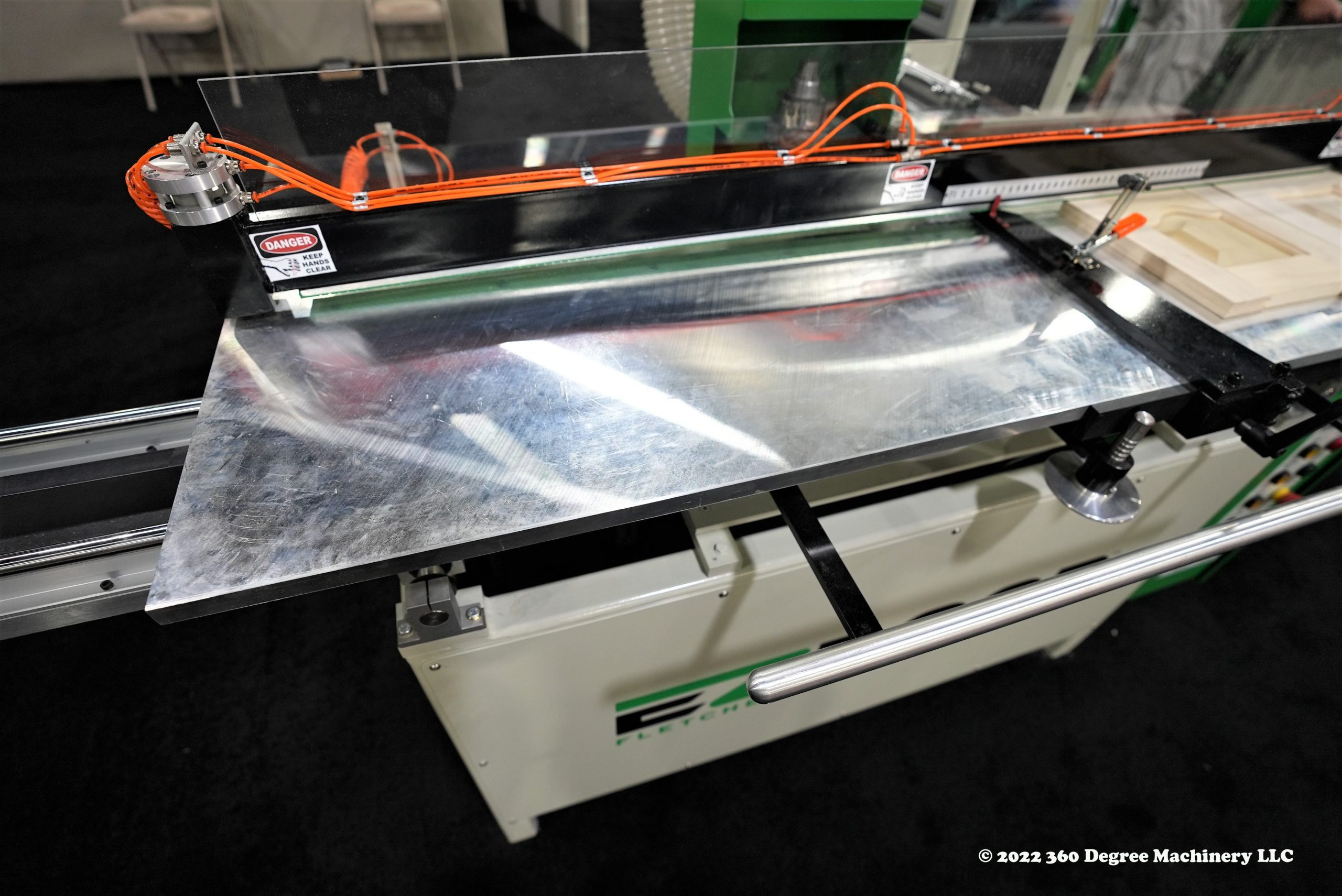

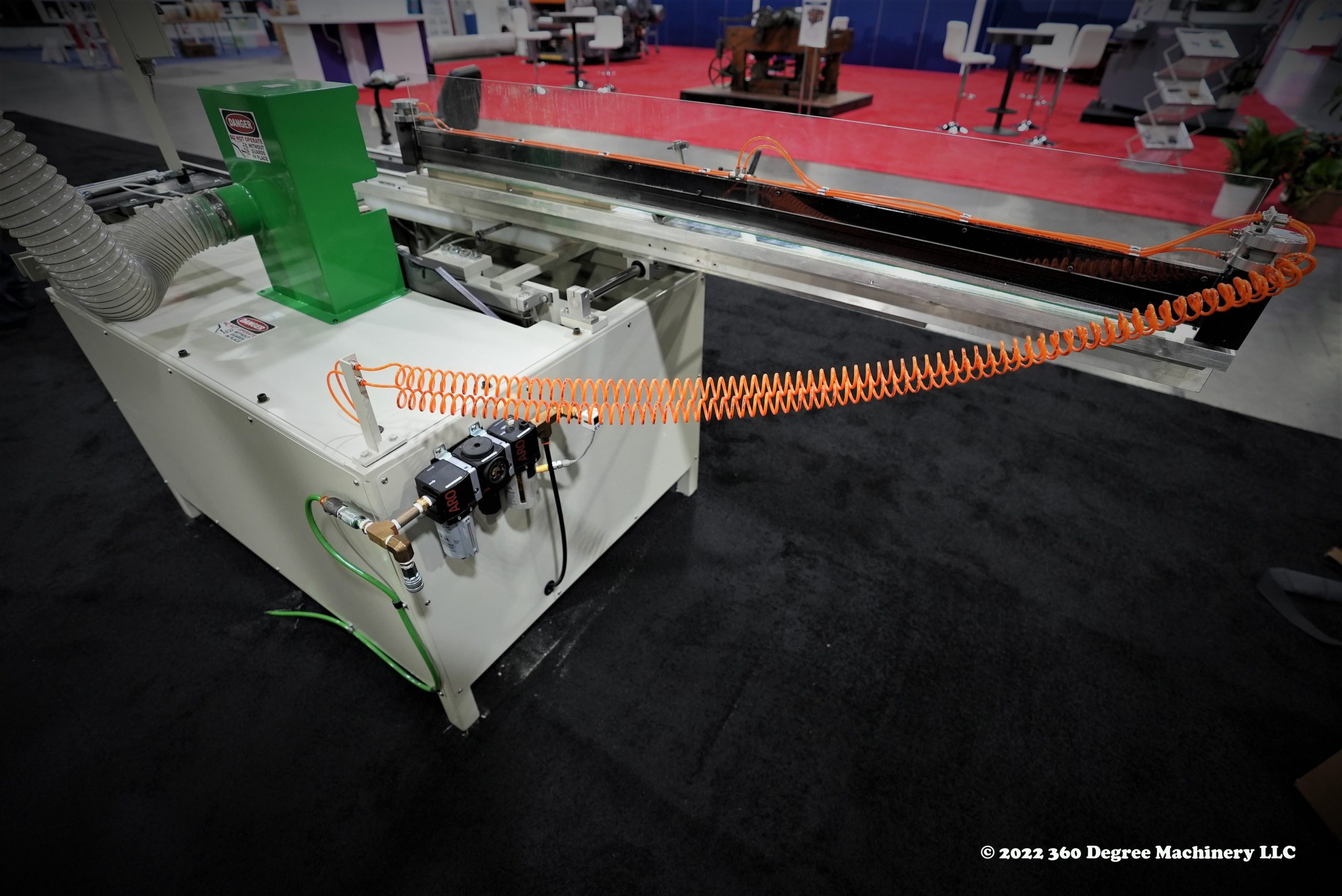

- 2-inch heavy wall steel tube framing guarantees every EZ Door machine is built with the same integrity as million-dollar high-speed, production equipment.

- Built tough. Built smart.

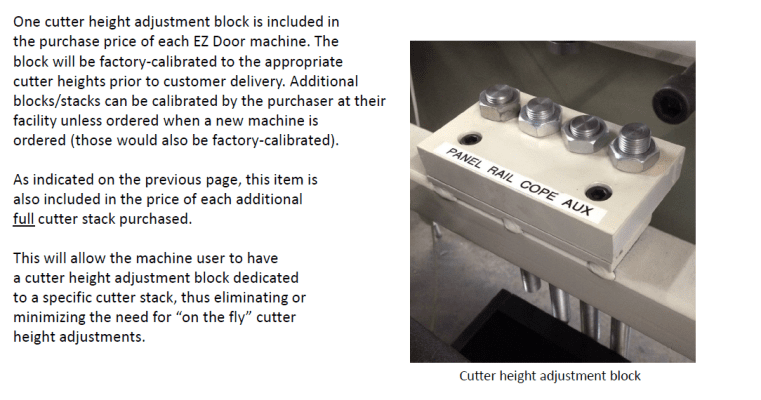

- A quick-change cutter height adjustment block can be calibrated for each cutter stack, eliminating the need for “on the fly” cutter height adjustments.

- Faster. Better.

But wait. There’s more:

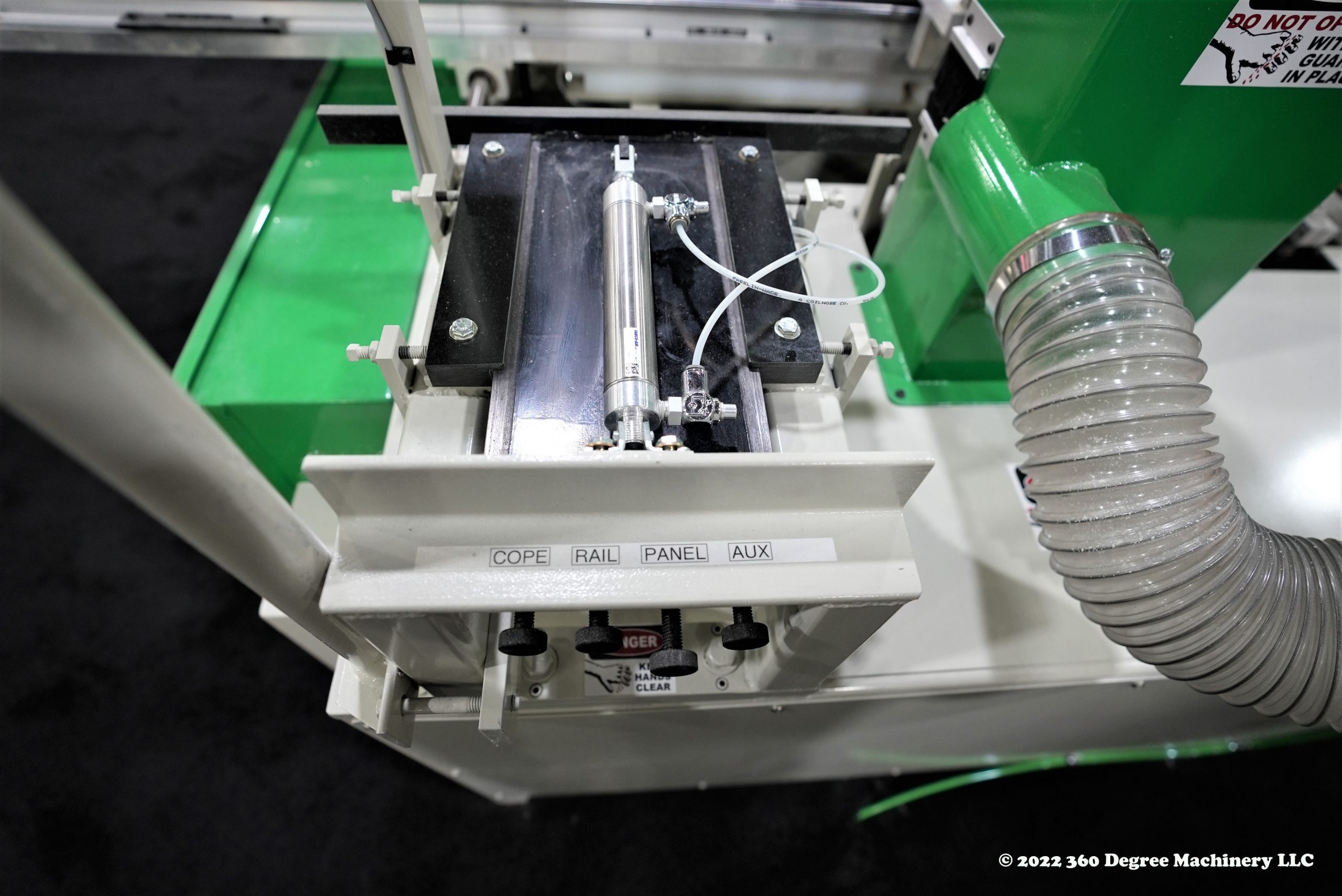

- Single-button selection for rail/stile, cope, panel, and door edge

- 10 HP 230/460V 60Hz spindle motor

- Safe, pneumatic clamping fence

- Standard arch template set included (7/8″ to 2″ arches)

- 62” table travel length standard with circulating ball bearing slides, cut rails to 59″ and panels to 55″

- All key functions PLC controlled

- Cut mullions for glass doors

- Cutter set included

- And, made and assembled in Lexington, NC

Specifications*:

| Motor | 10 HP 230/460V 60Hz, usable at 208V 60Hz |

| Stacked spindle | 6″ capacity, 1¼” bore |

| Air requirements | Minimum 70 PSI |

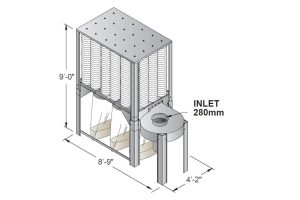

| Dust collection | 4″ for standard machine |

| Table | 62″ travel length for standard machine |

| Machine weight | 1250 lbs |

| Footprint | 112″ width by 39″ depth |

| Work height | 37″ to 39″ (adjustable) |

| Working width (table slides) | 96″ to129″ |

| Working depth (table slides) | 41″ to 48″ |

| Maximum arch width | 24 ½” for standard templates |

| Maximum straight-cut length | 59″ for rails, 55″ for panels |

| Maximum arch height | ⅞” to 2″ for standard templates |

| Maximum material thickness | 1″ for standard machine |

| Minimum rail material width | 1½” plus the depth of cut |

*The EZ-Door machine can be customized per your specifications. Call or email us to learn more. Specifications are subject to change.

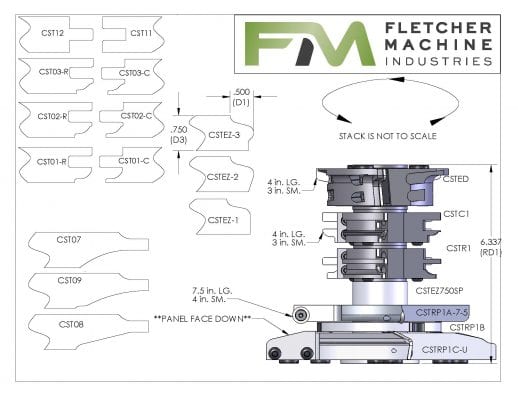

Door Tooling:

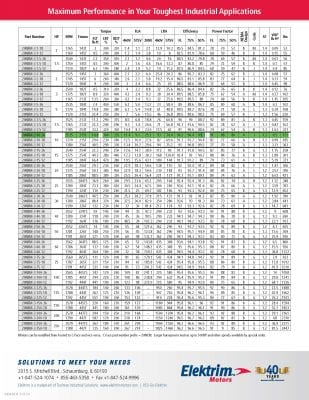

Motor Specifications: