Click here to Download Minimax SI X and Elite S range PDF Brochure

ADVANTAGE

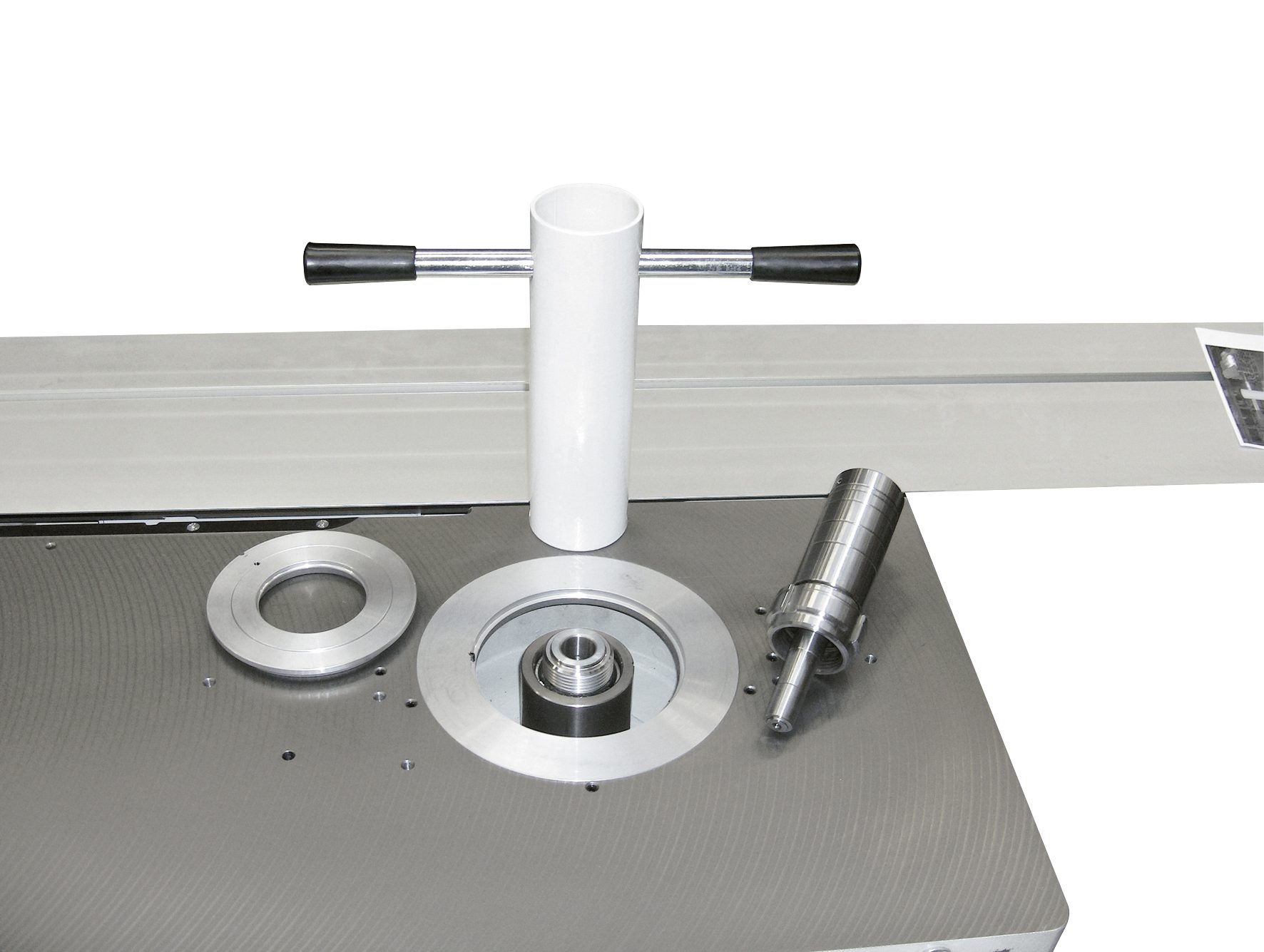

Unsurpassed moulding

Maximum stability and rigidity in all working conditions, thanks to a large spindle shaper column made entirely of cast iron. The 4 standard speed are ideal for any type of machining, from shaping to routing and tenoning, with the possibility to fit tools up to 320 mm of diameter (300 mm no CE).

High-tech accessories

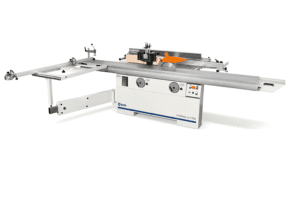

As option it is available the spindle shaper hood that uses a system for adjusting the guides with a rack and it is fitted with a mechanical digital readout. Thanks to the system of memories the hood can be removed and repositioned without losing the machining position. The maximum tool diameter during moulding operations is 240 mm.

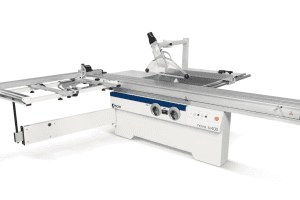

Unrivalled cutting finishing

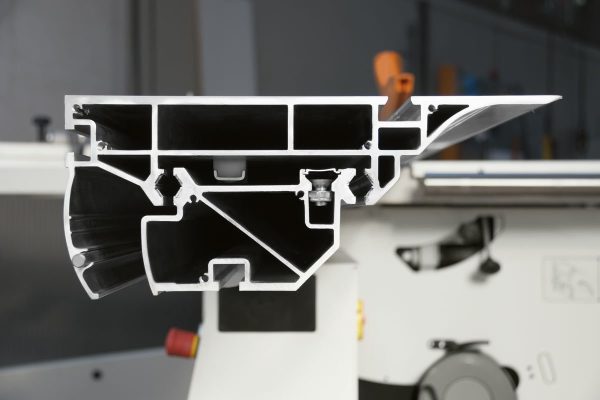

Optimal support also to larger pieces, with the new sliding table 360 mm wide. Exceptional precision and smoothness: to secure the guides it is not used glue, since the thickness could affect sliding. They are secured with a procedure of aluminum riveting.

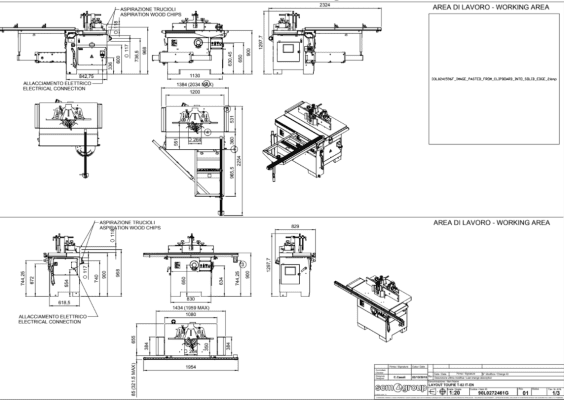

Technical data

| minimax tw 55es | ||

| Surfacing tables total length | mm | 125 |

| Spindle moulder speed (a 50 Hz) | rpm | 3500/6000/8000/10.000 |

| Max. tool diameter when profiling | mm | 210 ÷ 240 |

| Max. tool diameter lowered under the table at 90° | mm | 240 |

| Max. tool diameter when tenoning | mm | 320 (300 no CE) |

| Three-phase motors starting from | kW/Hz | 5 (6) / 50 (60) |