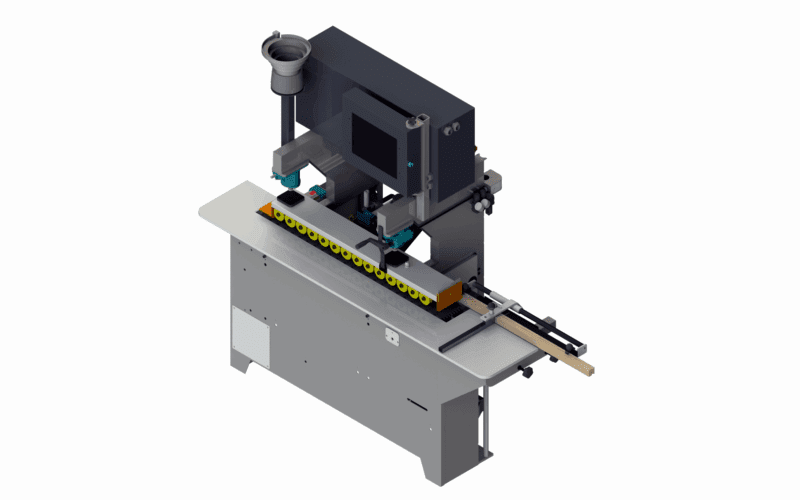

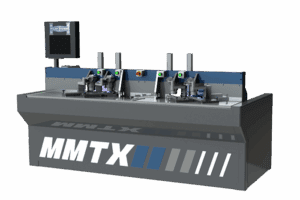

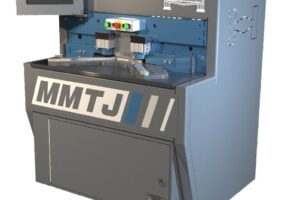

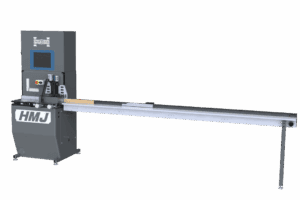

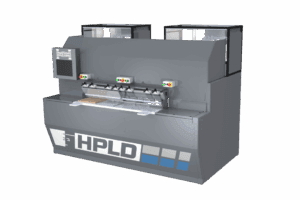

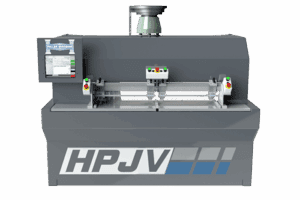

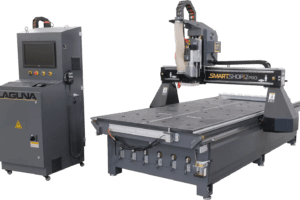

Pillar OTF: Continuous On-The-Fly CNC Dowel Insertion Machine

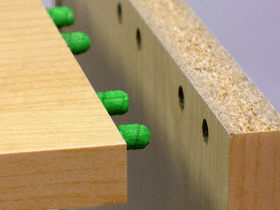

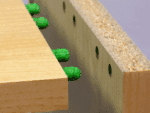

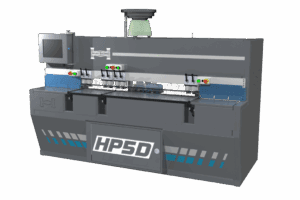

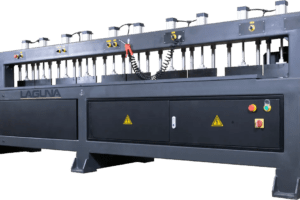

Propel your woodworking shop into high-speed production with the Pillar OTF, a cost-effective CNC dowel insertion machine designed for European-style cabinet box construction. Engineered for melamine-laminated particleboard, this on-the-fly system drills and inserts 8mm dowels as panels move continuously on a feed chain conveyor, eliminating downtime. Its true centerline referencing ensures symmetrical accuracy, with bidirectional processing and mirror mode for flexible panel handling. With its compact footprint and intuitive touchscreen, the Pillar OTF is the ultimate choice for cabinetmakers seeking rapid and precise assembly.

Standout Features and Advantages

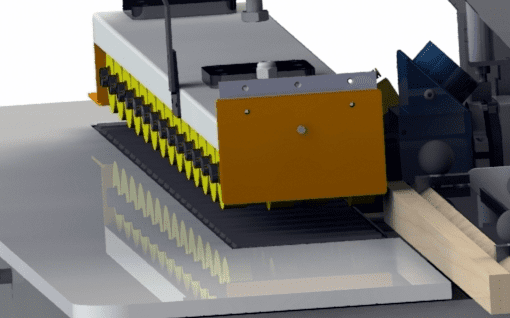

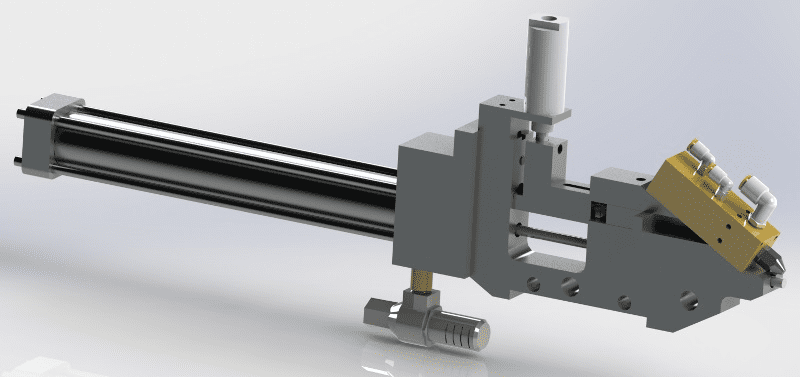

- On-The-Fly Efficiency: Drills and inserts 8mm dowels in a continuous conveyor process, maximizing throughput for high-volume shops.

- True Centerline Referencing: Operates from the panel’s centerline, enabling bidirectional processing or mirror mode for consistent Z-axis values.

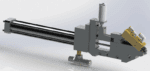

- High-Speed Spindle: 1 HP, 18,000 RPM direct-drive spindle ensures precise hole boring for optimal dowel fit and glue contact.

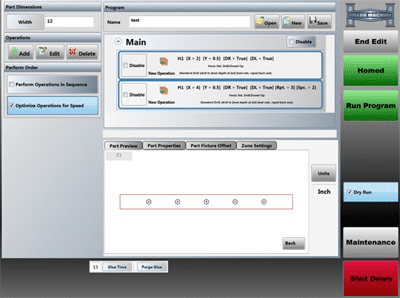

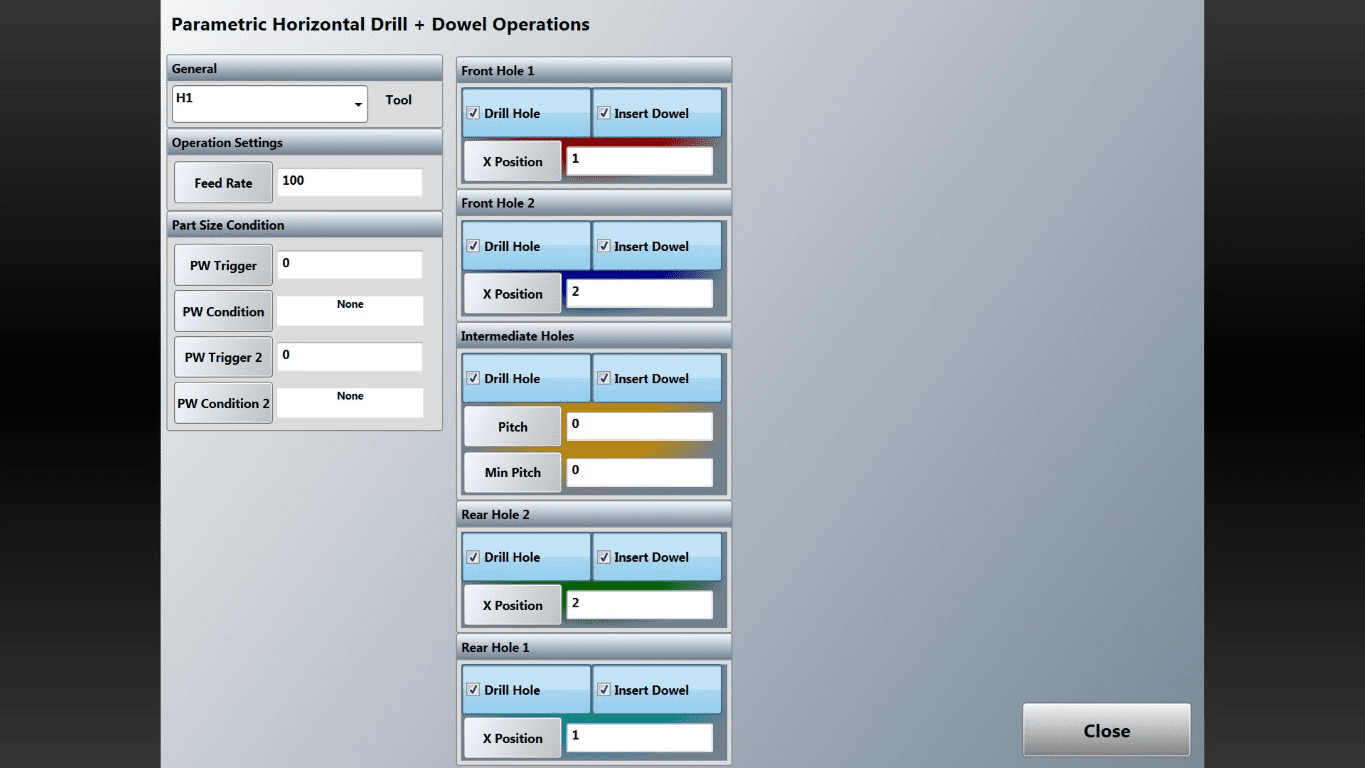

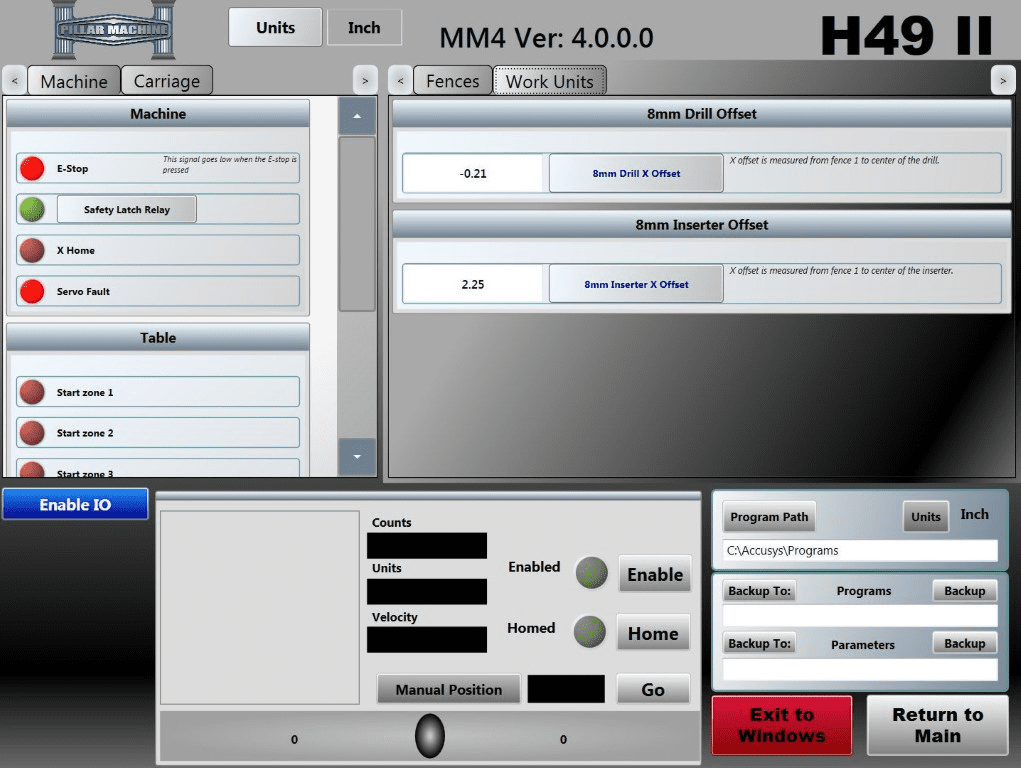

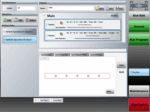

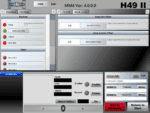

- Smart Touchscreen: 15″ industrial touchscreen with parametric programming and .xml file integration simplifies setup and operation.

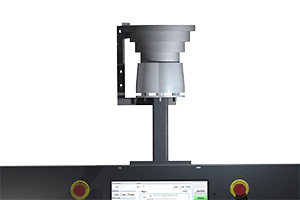

- Optional Upgrades: 18″ dowel bowl ($1,950) holds 3,000 dowels; fixed barcode reader ($1,600) automates part file loading.

- Compact Durability: 1,325 lb. frame with a 75″ x 36″ footprint, built for reliability in demanding environments.

Perfect For

The Pillar OTF is tailored for:

- High-volume cabinet shops assembling European-style boxes with melamine-laminated particleboard.

- Manufacturers seeking continuous, automated dowel insertion to streamline production.

- Workshops needing compact, cost-effective CNC solutions with flexible panel handling.

Technical Breakdown

| Feature | Specification |

|---|---|

| Machine Type | On-the-fly CNC dowel insertion |

| Material Length | Min: 4″; Max: Unlimited |

| Material Thickness | Min: 1″; Max: 1″ |

| Dowel Size | 8mm diameter (standard) |

| Spindle Motor | 1 HP, 18,000 RPM direct-drive |

| Conveyor System | 6″ wide heavy-duty track, 14.5″ wide table |

| Controls | 15″ industrial touchscreen |

| Software Tools | Parametric programming, .xml integration, online diagnostics |

| Electrical | 3-phase, 208-240V, 50-60 Hz, 20 amps |

| Compressed Air | 90 PSI at 5 CFM |

| Dust Collection | 1 x 2.5″ port, 220 CFM |

| Dimensions | 75″ L x 36″ W |

| Weight | 1,325 lbs. (approx.) |

Smart Software & Interface

The Pillar OTF’s 15″ touchscreen is a user-friendly control center, enabling program setup in under a minute. Its open-architecture software supports .xml file imports, barcode scanning (optional reader), and parametric programming compatible with Cabinet Vision and Microvellum. Key features include:

- Graphical interface for dowel placement and drilling.

- Parametric programming for flexible dowel spacing.

- Online diagnostics for maintenance (with internet).

Why Pillar Excels

Handcrafted in Salt Lake City, Utah, every Pillar OTF embodies American engineering excellence, backed by a one-year warranty and free online training. Pillar’s innovative designs and direct factory support ensure lasting value, trusted by woodworking professionals for precision and reliability.

Request Your Customized Quote from 360 Degree Machinery

Ready to streamline your cabinet box assembly? Click the “Add to quote” button above or call 630-229-6705 to request a customized quote for the Pillar OTF today!