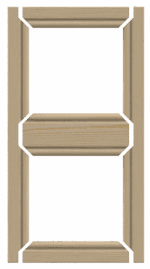

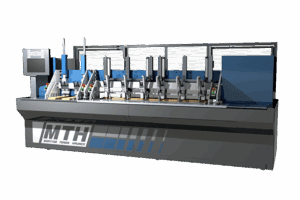

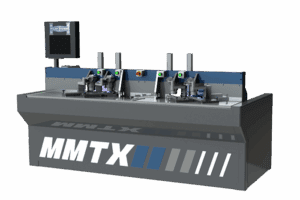

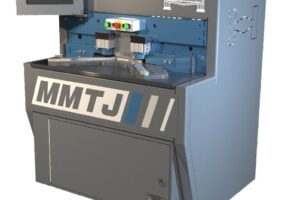

Pillar HMJ: CNC Haunch Machine for Beaded Face Frames

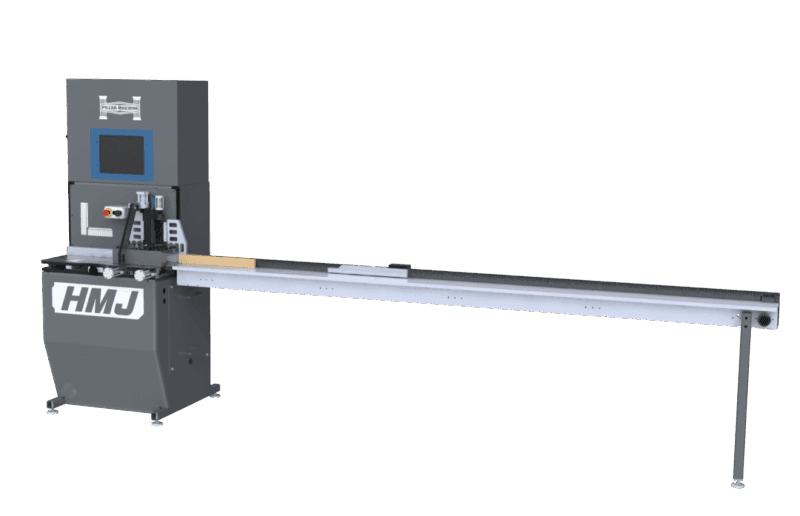

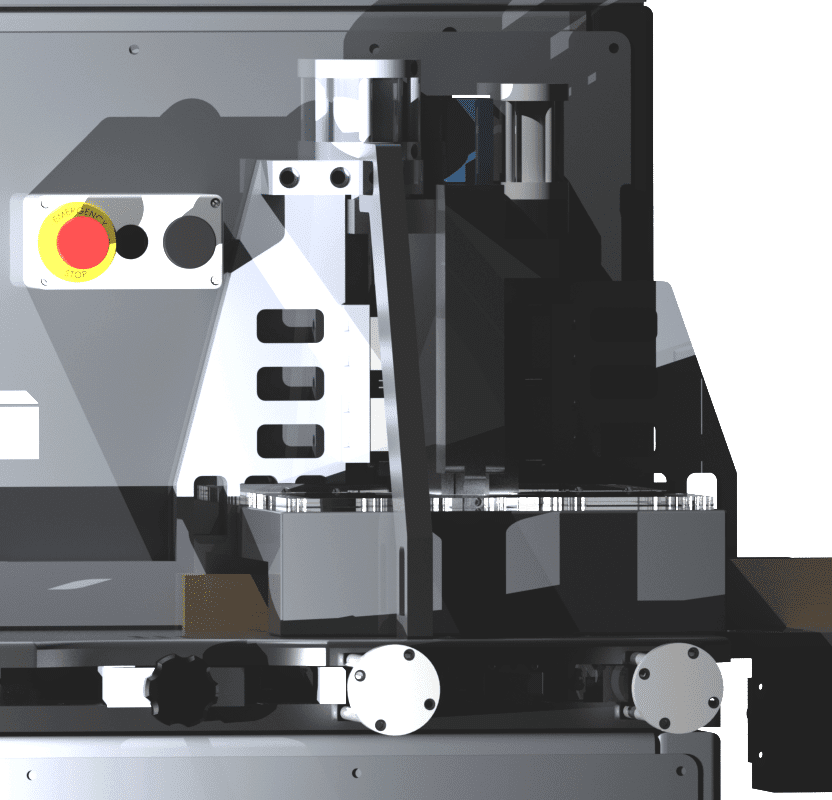

Transform your woodworking shop with the Pillar HMJ, a CNC machining center engineered for crafting high-quality haunch joints in beaded face frames for cabinets and furniture. Recognized as an IWF Challengers semi-finalist, this jump haunch machine miters profiles on stiles and rails with precision, producing self-aligning joints that ease assembly. Its ability to stack two parts for simultaneous cutting doubles output, while its compact footprint fits seamlessly into any shop. With a user-friendly touchscreen and servo-driven controls, the Pillar HMJ delivers speed, accuracy, and efficiency for woodworking professionals.

Standout Features and Advantages

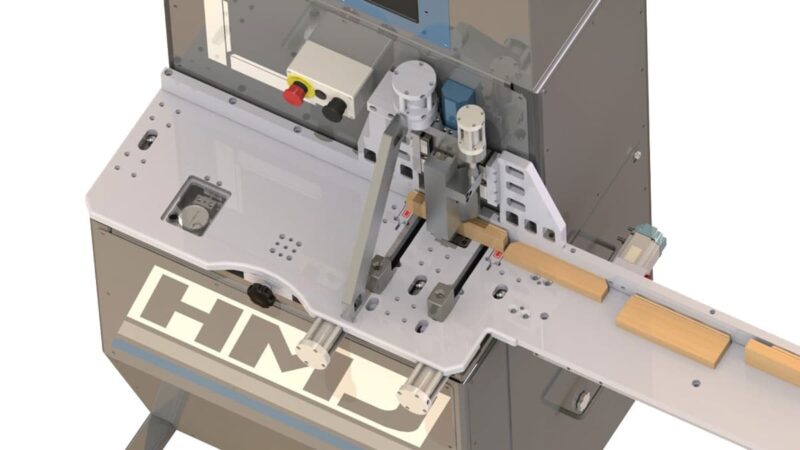

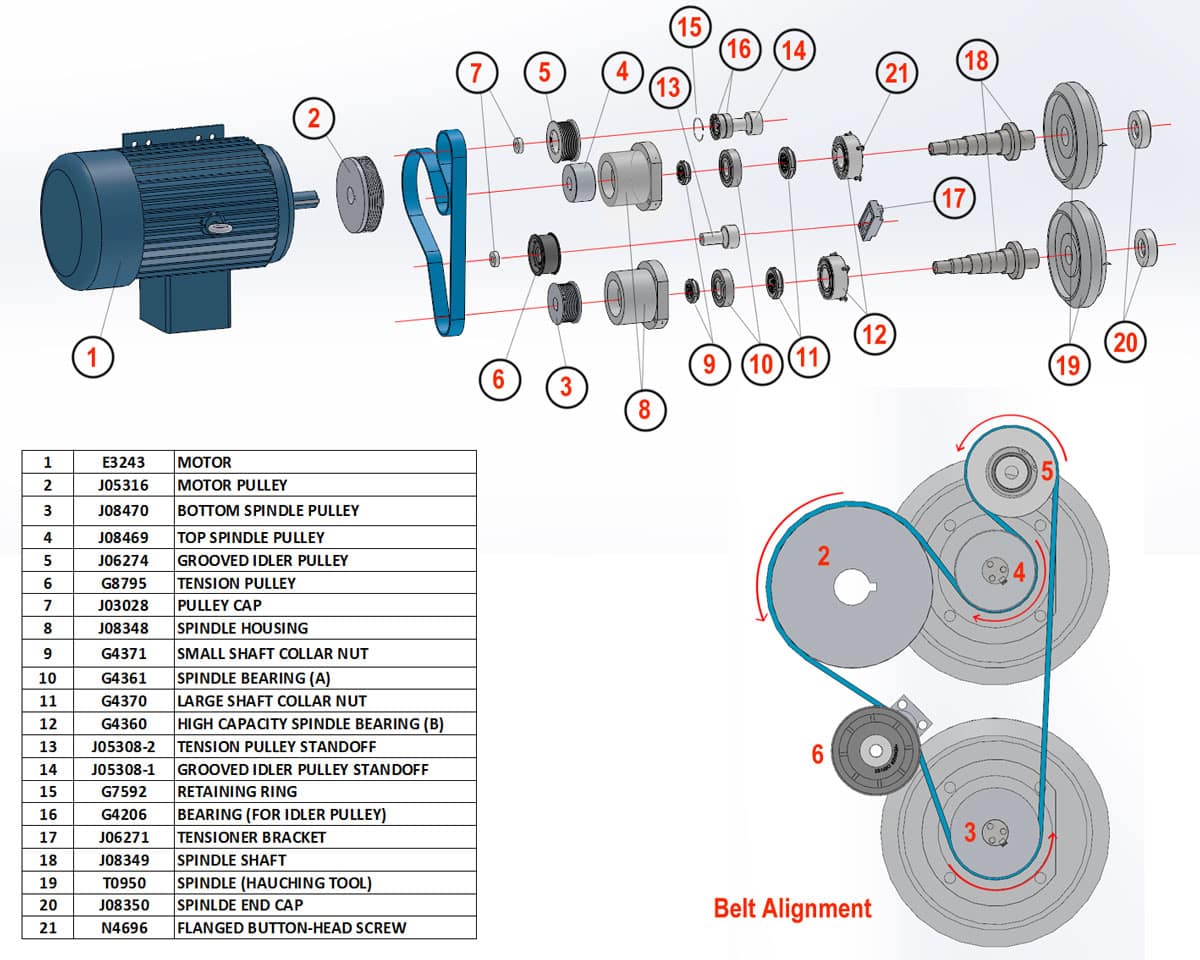

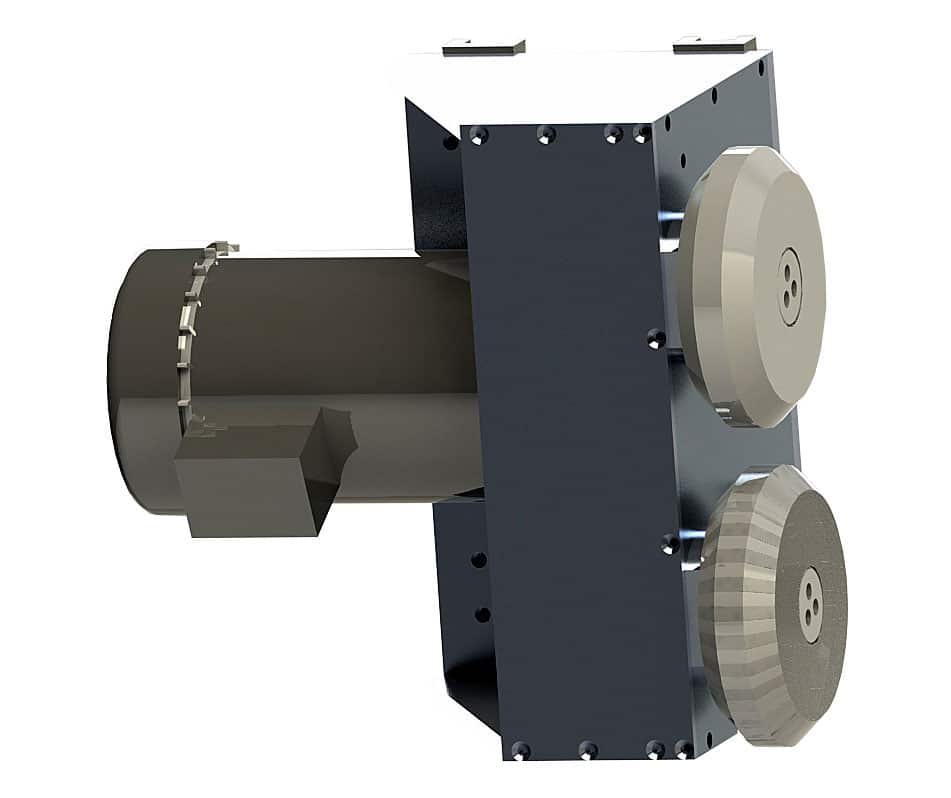

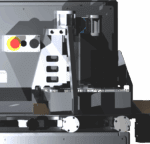

- CNC Haunch Precision: Servo-driven X-axis with belt control miters profiles for tear-out-free haunch joints on beaded face frames.

- Doubled Output: Stacks two stiles or rails for simultaneous cutting, boosting production without extra labor.

- Self-Aligning Joints: Produces joints that simplify assembly, reducing time and effort in cabinet and furniture construction.

- Compact Footprint: Measures 177″ W x 37″ D x 82″ H, ideal for shops with limited space yet needing high output.

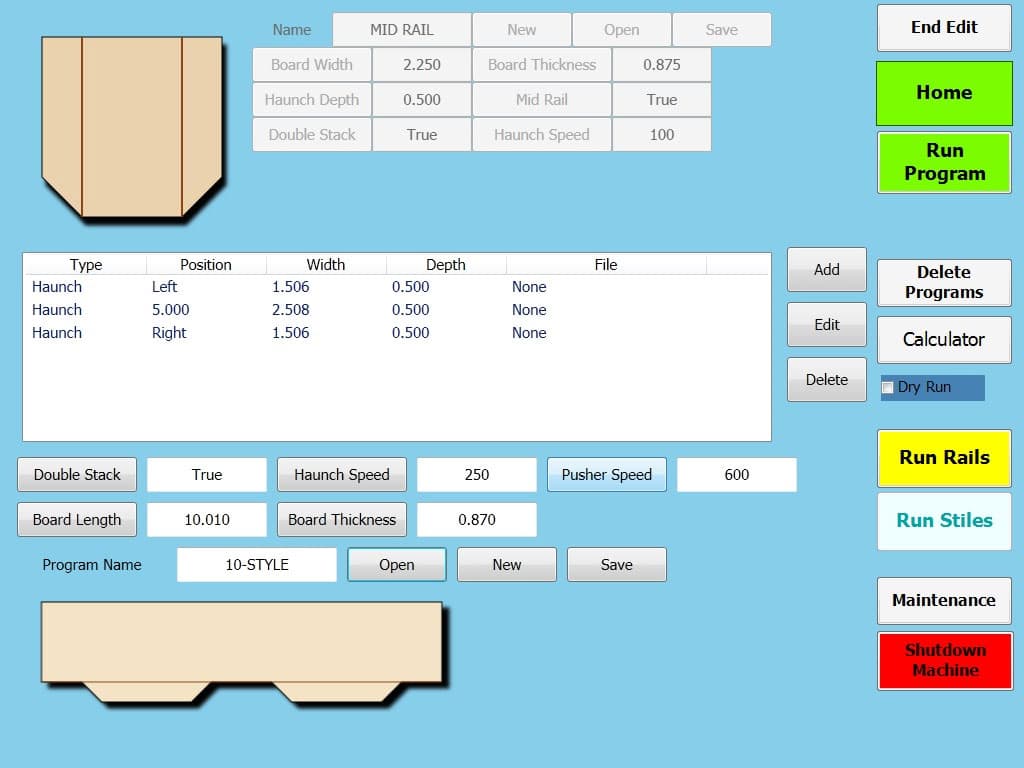

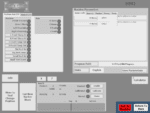

- Intuitive Interface: A 15″ industrial touchscreen with open-architecture software enables quick program setup and unlimited storage.

- Rugged Durability: 1,400 lb. frame with high-precision square rail guides ensures reliable performance in demanding environments.

Perfect For

The Pillar HMJ is tailored for:

- Cabinet and furniture shops crafting beaded face frames with haunch joints.

- Manufacturers seeking to automate manual haunching for faster, more accurate production.

- Workshops needing a compact, high-efficiency CNC machine for medium to large runs.

Technical Breakdown

| Feature | Specification |

|---|---|

| Machine Type | CNC haunch machine for beaded face frames |

| Production Capacity | Stackable parts for doubled output |

| Material Compatibility | Beaded face frame stiles and rails |

| X-Axis Control | Servo belt-driven part stop |

| Guides | High-precision square rail guides and bearings |

| Display | 15″ industrial touchscreen |

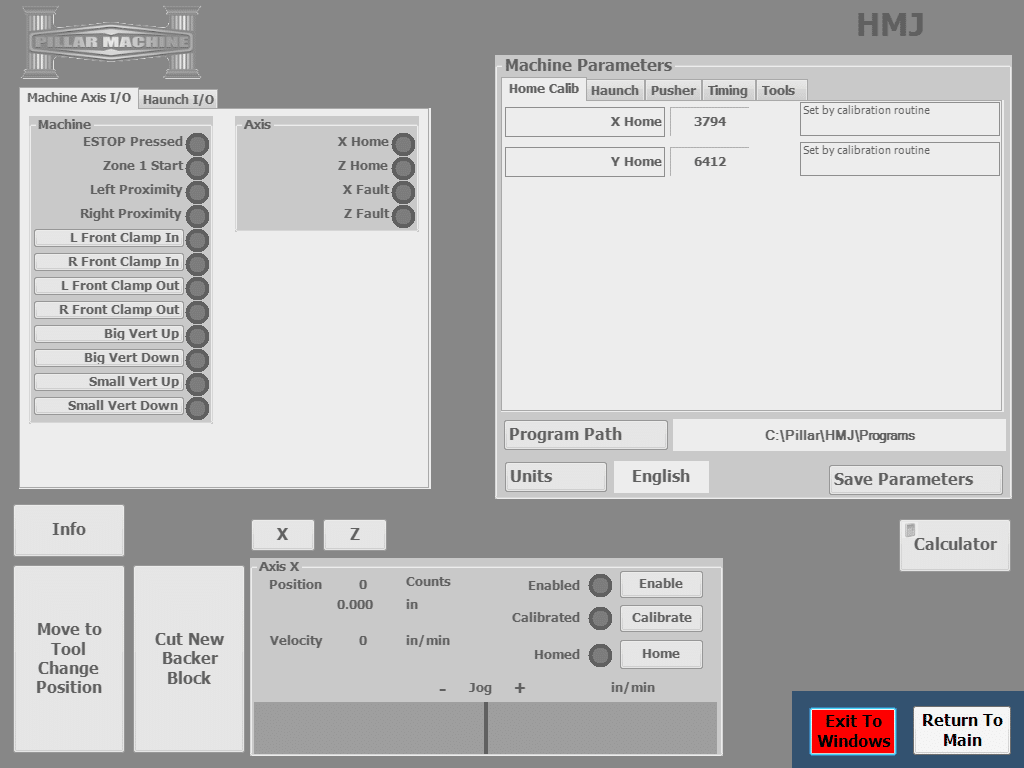

| Software Tools | Parametric programming, unlimited program storage, online diagnostics |

| Dimensions | 177″ W x 37″ D x 82″ H |

| Weight | 1,400 lbs. (approx.) |

| Electrical | 3-phase, 208-230V, 60 cycles, 20 amps |

| Compressed Air | 90 PSI at 5 CFM |

| Dust Collection | 2 x 4″ ports, 696 CFM total |

Smart Software & Interface

The Pillar HMJ’s 15″ touchscreen is a control hub designed for simplicity, allowing program setup in seconds. Its open-architecture software supports .xml file imports or barcode scanning (optional reader required), ensuring a smooth workflow. Key features include:

- Visual guides for haunch joint placement.

- Parametric programming for custom setups.

- Unlimited program storage and online diagnostics (with internet).

Available HMJ Options

Additional Guarding

Adds welded tube‑steel and expanded‑mesh panels with hinged access doors for enhanced safety and a more enclosed work area—ideal when the machine’s back will be exposed.

Automatic Oiler System

Automatic Oiler System

Includes a pneumatic automatic oiler that delivers oil-lubricated compressed air to key linear bearings (X‑axis, drill‑spindle, groove‑spindle) whenever the spindle runs. Helps prevent dust-related wear. Note: may affect lead time.

Fixed‑Mount Barcode Reader

Enables operators to scan barcodes on parts to automatically load the correct program via the included software. Comes with one fixed reader. Note: may affect lead time

Why Pillar Excels

Built in Salt Lake City, Utah, every Pillar HMJ reflects American engineering excellence, backed by a one-year warranty and free online training. Pillar’s innovative designs and direct factory support ensure lasting value, trusted by woodworking professionals for precision and reliability.

Request Your Customized Quote from 360 Degree Machinery

Ready to streamline your face frame production? Click the “Add to quote” button above or call 630-229-6705 to request a customized quote for the Pillar HMJ today!