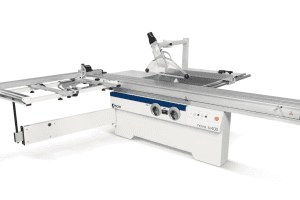

Click here to Download Minimax SI X and Elite S range PDF Brochure

Incredible cutting thanks to the saw unit with a blade (not included) that has a maximum diameter of 315 mm with the scoring blade installed

Optimal support also to larger pieces, with the sliding table 360 mm wide. The guides are secured with a procedure of aluminum riveting, so that to ensure an exceptional precision and smoothness

The planer infeed roller has a helicoidal profile to guarantee firm and constant work piece feed, while the outfeed roller, in sandblasted steel, maintains the perfect post-processing finishing

SCM Thundercut App for mobile devices: optimizer/sequencer even for not skilled workers

Maximum stability and rigidity in all working conditions, thanks to a large spindle moulder column made entirely of cast iron

Technical data

| cu 410c | ||

| Working width (thicknessing planer) | mm | 410 |

| Surfacing tables total length | mm | 1800 |

| Max. sawblade diameter with scoring blade installed | mm | 315 |

| Max. sawblade projection from table at 90°/45° | mm | 100/78 |

| Cutting widh on parallel fence | mm | 900 |

| Max. useful spindle length | mm | 100 |

| Max. tool diameter when profiling | mm | 210 |

| Spindle moulder speed (a 50 Hz) | rpm | 3500/7000/10.000 |

| Three-phase motors starting from | kW/Hz | 5 (6) / 50 (60) |