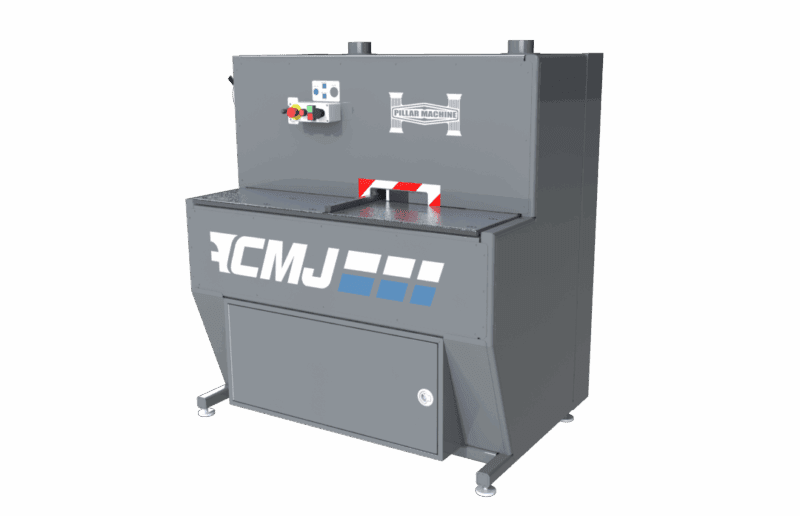

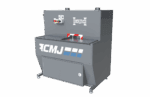

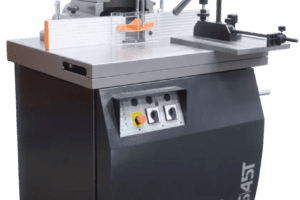

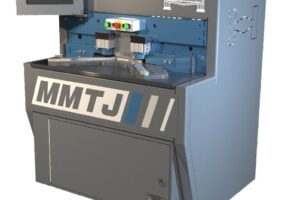

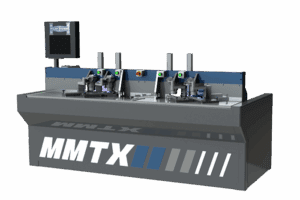

Pillar CMJ: Coping Machine for Precision Rail End Finishing

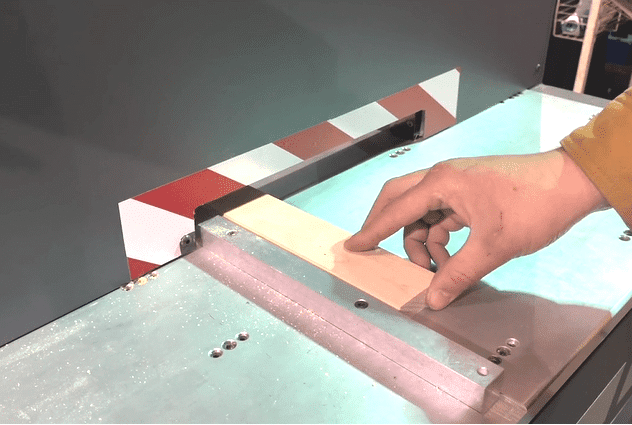

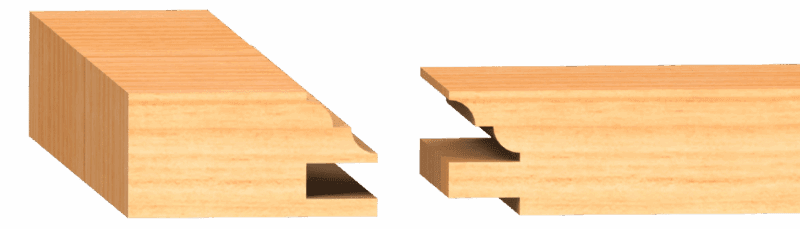

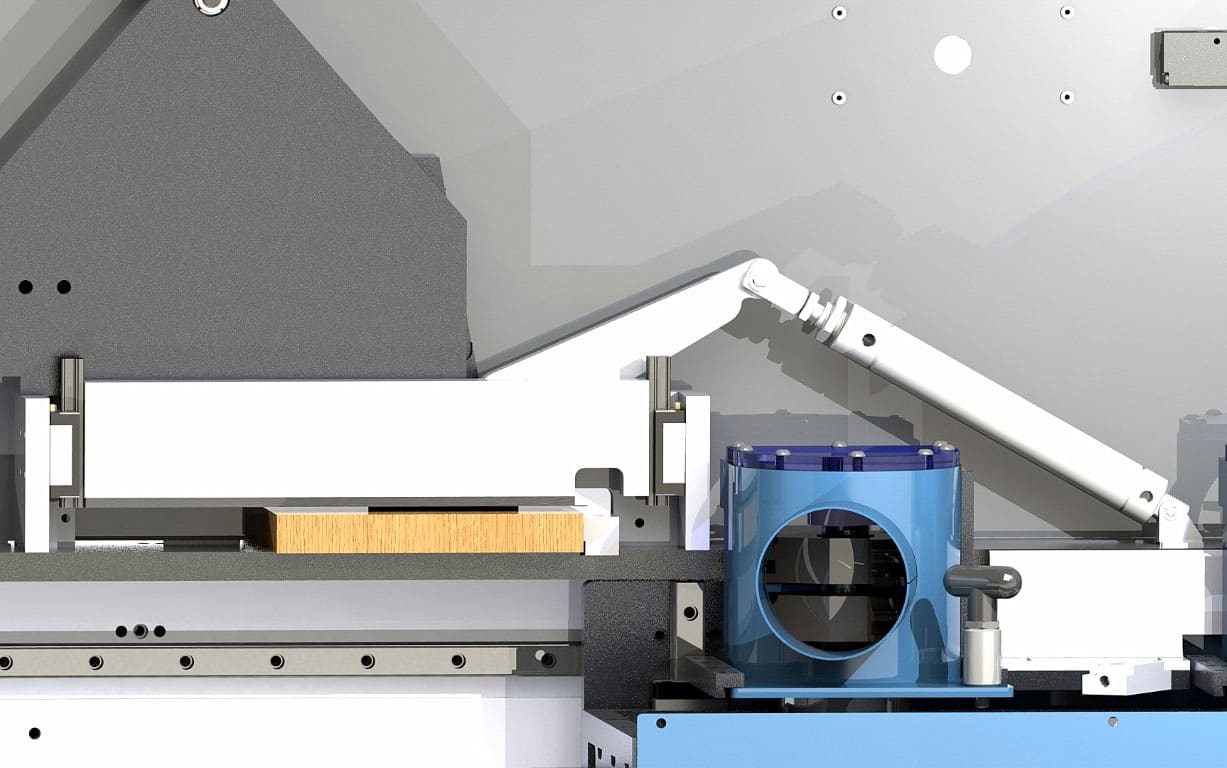

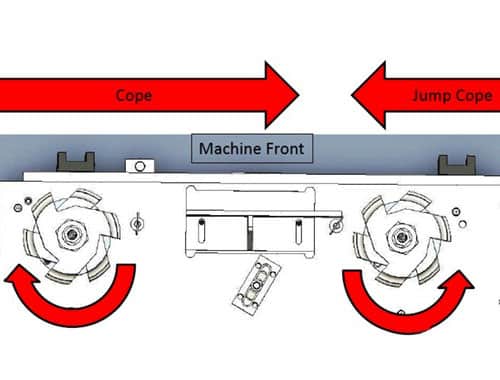

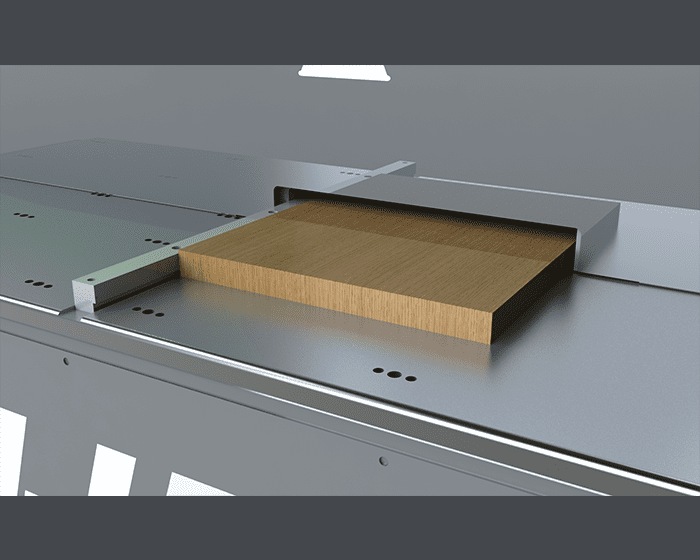

Revolutionize your cabinet door production with the Pillar CMJ, a high-performance coping machine designed for chip-free end coping, tenoning, finger jointing, and end matching. Perfect for woodworking shops, this machine processes square or profiled rail ends without backer blocks or chip breakers, delivering tear-out-free results in a swift 6-8 second cycle. Its dual counter-rotating spindles and PLC controls ensure simplicity and precision, while the ability to switch between two profile tools with a single flip of a switch boosts versatility. With a compact footprint and robust construction, the Pillar CMJ is your key to enhancing shop productivity and quality.

Standout Features and Advantages

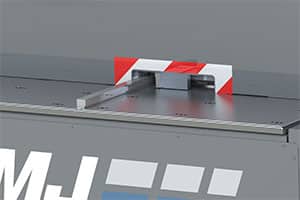

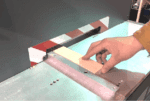

- Chip-Free Precision: Two counter-rotating vertical spindles clear the leading edge and process the full width, ensuring clean, tear-out-free cuts every time.

- Lightning-Fast Cycles: Completes coping or tenoning in 6-8 seconds, capable of processing up to 4000 rails per shift when cutting two parts at once.

- Tool Versatility: Supports two sets of profile tools simultaneously, with quick switching for seamless transitions between setups.

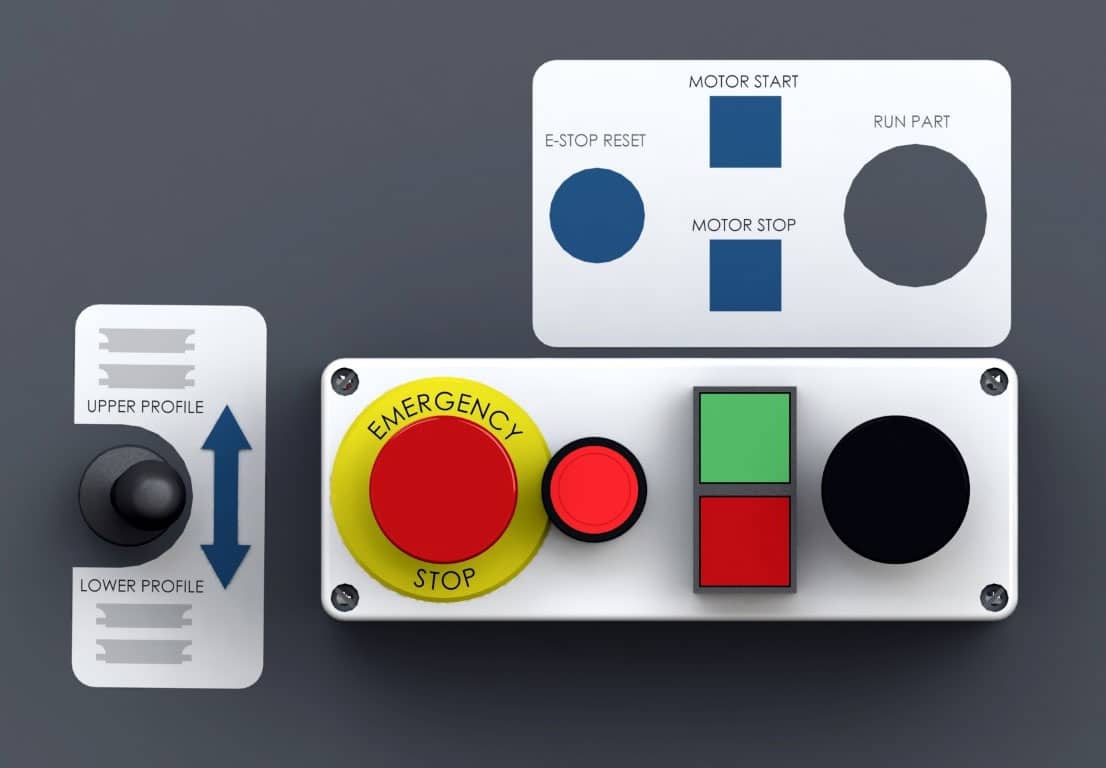

- Simple Operation: PLC controls with intuitive settings make it easy for operators to achieve consistent results, even with minimal training.

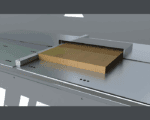

- Compact Design: Measures 52″ W x 30″ D x 57″ H, fitting efficiently into shops with limited space.

- Durable Build: 1,200 lb. frame with high-precision square rail guides ensures long-lasting performance in busy environments.

Perfect For

The Pillar CMJ is ideal for:

- Cabinet shops needing fast, precise coping and tenoning for door rails.

- Woodworkers processing pre-profiled or square parts without backer blocks.

- Manufacturers seeking a compact, high-output machine for medium to large runs.

Technical Breakdown

| Feature | Specification |

|---|---|

| Machine Type | Coping, tenoning, finger jointing, end matching machine |

| Cycle Time | 6-8 seconds per part |

| Production Capacity | Up to 4000 rails per shift (dual parts) |

| Material Compatibility | Square or profiled parts |

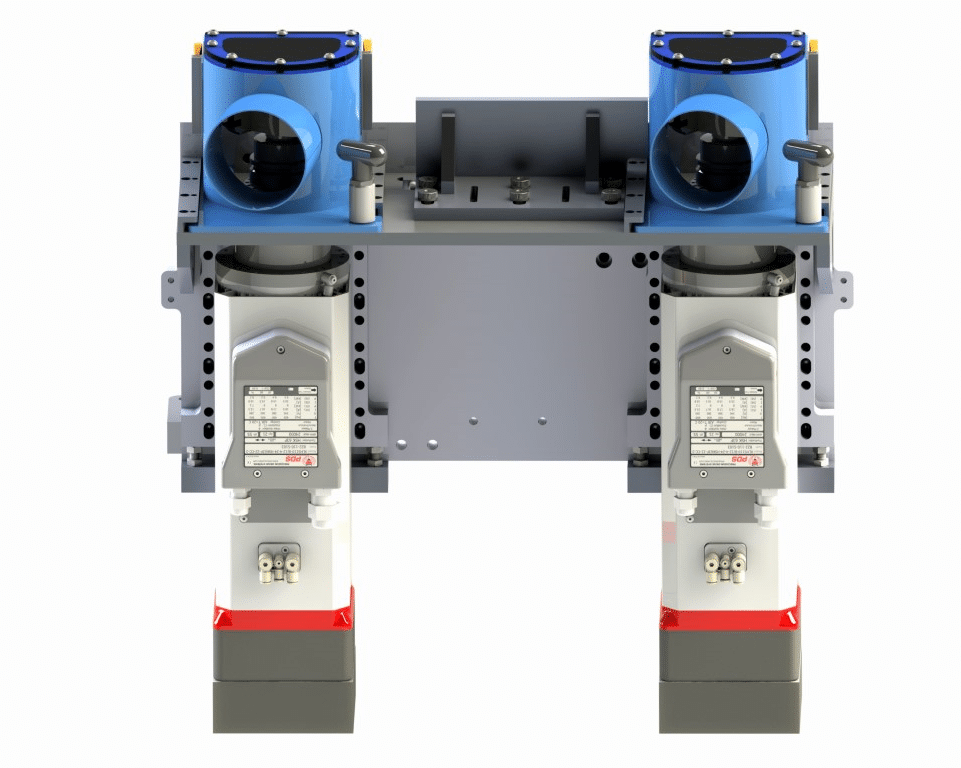

| Spindles | 2 counter-rotating vertical spindles, 5 HP motor |

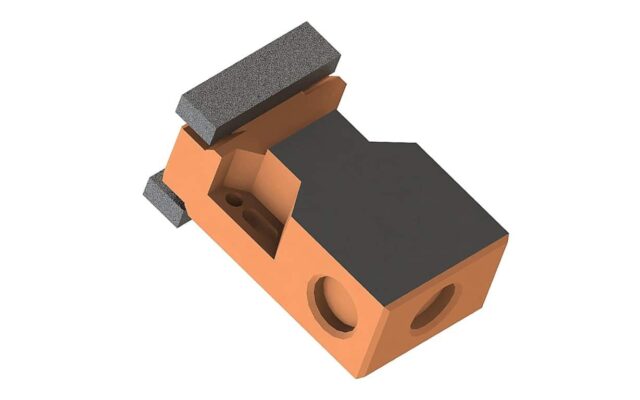

| Clamp Force | Scissor lock clamp, up to 600 lbs. |

| Controls | PLC with programmable settings |

| X-Axis Guides | High-precision square rail guides and bearings |

| Electrical | 3-phase, 208-230V, 60 cycles, 30 amps |

| Compressed Air | 90 PSI at 5 CFM |

| Dust Collection | 2 x 4″ ports, 696 CFM total |

| Dimensions | 52″ W x 30″ D x 57″ H |

| Weight | 1,200 lbs. (approx.) |

Available CMJ Options

Rear Guarding Upgrade

Includes hinged tube‑steel and expanded‑mesh access doors at the back for enhanced safety and visibility. Note: Welded-on, may extend lead time and increase machine depth to 40 inches.

Keyed Electronic Interlock

Integrates into rear guard doors to function as an emergency stop switch. Note: may extend lead time.

Foot Pedal Control

Replaces the palm-button start with a floor pedal, allowing hands-free operation. Note: may extend lead time.

HSK Spindle Option Package

Upgrades to two dedicated 11 HP HSK-63F spindles.

Automatic Oiler System

Delivers adjustable, pressurized lubrication to bearings (8 total: 4 × X‑axis, 4 × under spindles). Operates whenever the spindle runs. Note: may extend lead time.

12-Inch Part Width

Increases the CMJs’ maximum width capacity from the standard 8″ to a maximum of 12″ to accommodate wider components.

Why Pillar Excels

Handcrafted in Salt Lake City, Utah, every Pillar CMJ embodies American engineering excellence, backed by a one-year warranty and free online training. Pillar’s legacy of innovation and direct factory support ensures your machine delivers lasting value, trusted by woodworking professionals for its precision and reliability.

Request Your Customized Quote from 360 Degree Machinery

Ready to speed up your rail end finishing? Click the “Add to quote” button above or call 630-229-6705 to request a customized quote for the Pillar CMJ today!