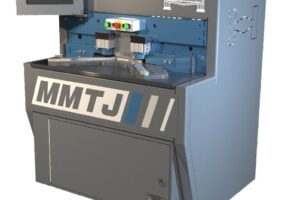

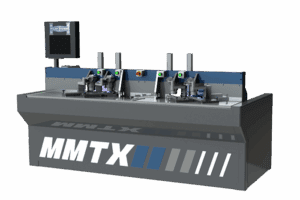

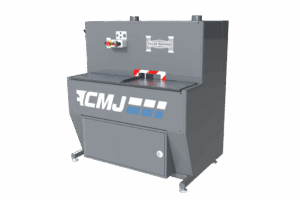

Tenon Cutterhead

- Both top and bottom tenon heads can be individually or simultaneously vertically adjusted.

- Individual cross adjustment in 1″ distance.

- Helical and straight tenon cutter heads on the 152 series provide excellent quality results on a range of materials.

Cope Head

- For fitting with pattern cutter producing various end patterns.

- The cope spindle may be vertically or crosswise adjusted.

- Vertical movement distance is 3.625”

- Forward and backward movement distance is 3.4”.

Cutoff Saw

- The saw mechanism is mounted in front of tenon heads for cutting stock to the desired length.

- The saw blade may be vertically adjusted.

- The saw head accepts a 12″ maximum blade diameter.

Sliding Table

- Table slides on precision machined “V” ways, precise sliding accuracy is assured.

- The bearing support permits for effortless hand moving of the table.

Extended Aluminum Ruler

- Use the extendable aluminum ruler to measure the required length of the workpiece.

- Equipped with two work stops for convenient repetitive cutting.

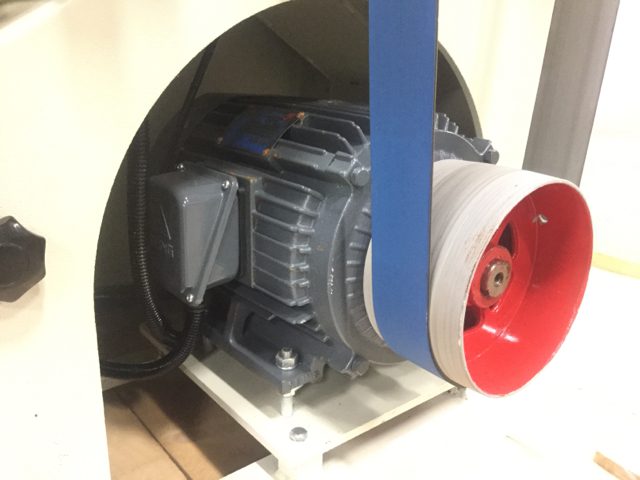

Saw Blade Guard and Dust Filter

- An added saw blade guard offers added safety for the operator.

- A filter screen is provided in front of the dust hood to prevent chips from entering the dust collector.

Specifications:

- Machine Hp. = 12.5 hp.

- Voltage/ Freq. = 230 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 36.6 Amp

- Spindle Diam. = (3) 1-1/4”

- 1st Head = 12” 2900 Rpm 100T Cutoff Saw

- 2nd Head = 4” x 6” 3400 RPM Tenon Head

- 3rd Head = 4” x 6” 3400 RPM Tenon Head

- 4th Head = 6” 6000 RPM Cope Head

- Feed System = Sliding Table

- Drive System = Manual

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 110 Volt

- Pass-Line = 32”

- Cut Envelope = 4-1/8” x 14-1/2”

- Min. Length = 8”

- Max. Length = Infinite

- Min. Width = 1″

- Max. Width = 14-1/2”

- Min. Thickness = 3/16″

- Max. Thickness = 4-1/2”

- Rows of Cutters = 6 Rows

- No. of Inserts = 39 Inserts

- Insert Size = 15 x 15 x 2.5 mm

- Dust Collection = (3) 4” @ 1308 CFM

- Dust Port Out = (3) 4” Outlets

- Hold Down Style = Pneumatic Clamp

- FLR Included = Filter, Lubricator, Regulater

- Recommended CFM = 1350 Total CFM

- Emergency Stop = Push Button

- Guarding = High Visibility Guarding

- Operation Style = Manual

- Fence Type = Adjustable Fence

- Fence Dims. = 2” x 72”

- Sliding Table = 43-3/4” Travel

- Frame Const. = 1/2” Steel Construction

- Worktable Dims. = 39” x 15-1/2” x 32”

- Table Const. = Machined Steel

- Measure Meth. = Digital Position Readout

- Decible Rating = 82 dB

- Net Weight = 1322 Lbs.

- Gross Weight = 1587 Lbs.

- Machine Dims. = 94” x 72” x 58”

- Packaging Dims = 66” x 30” x 53”