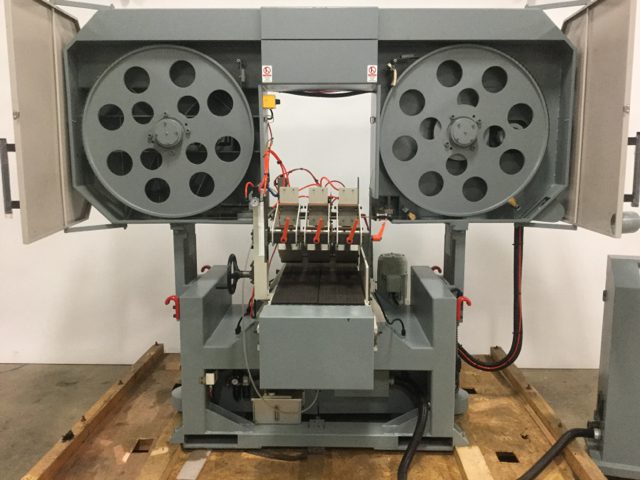

Features:

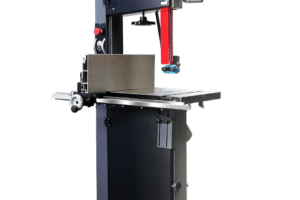

- Maximum cutting capacity: W 16″ x H 10.75″

- Minimum thickness: 2mm (.07″)

- Saw wheel diameter: W 2″ x H 36″

- Saw blade length: 6060mm (238 ½”)

- Saw blade width: 75mm (3″), (2″ is optional)

- Steel chain conveyor belt: 400mm (16″)

- Conveyor height (from the floor): 926mm (36 ½”)

- Feed speed: 5-55 FPM

- Feed inverter motor: 3HP with 5HP variable frequency drive

- Saw wheel motor: 40HP with 50HP variable frequency drive

- Blade lift motor: ¾ HP on precision ball screw lifting system

- 1HP pump for hydraulic blade tensioning system

- Dust ports: (2) 4″

- Dust collection requirements: 450 CFM @ points of extraction

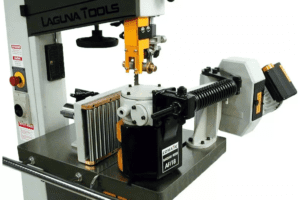

- Touch screen control panel

- Precision blade guides from tungsten carbide

- Power return conveyor (Optional)

- All machines are tested stateside prior to shipment providing trouble-free start-up.

Specifications:

- Main Motor Hp. = 40 hp.

- Voltage/ Freq. = 460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 56.67 Amps

- Feed Hp. = 3 Hp.

- Feed System = 16” Chain Feed

- Drive System = Chain Drive

- Feed Speed = 5 – 55 FPM

- Variable Speed = Inverter Controlled

- Elevation Hp. = 3/4 Hp.

- Elevation Style = Auto Touch Screen Control

- Elevation Sys. = (2) Post Jack Screw

- Total Hp. = 44.5 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 230 Volt

- Programmable = Feed Speed / Blade Speed

- Touch Screen = 7” Digital Touch Screen

- Operator Panel = Mobile Cabinet

- Min. Length = 14”

- Min. Width = 2″

- Max. Width = 16”

- Min. Thickness = .07”

- Max. Thickness = 10-3/4”

- Blade Size = 238-1/2”

- Tooth Spacing = 1”

- Blade Kerf = .086 In.

- Blade Speed = 3850 – 7150 FPM

- Tracking Style = Manual Adjustment

- Tension Style = Hydraulic Tension

- Vertical Travel = .07” – 10-3/4”

- Dust Collection = (2) 4” @ 900 CFM

- Dust Port Out = 2 4” Top

- Conveyor = 16” Chain Conveyor

- Chain Adj. = Manual

- Hold Down Style = 3 Front 2 Rear Pneumatic

- FLR Included = Filter, Lubricator, Regulator

- Recommended CFM = 872 Total CFM

- Emergency Stop = Push Button

- Rear E Stop = Push Button

- Guarding = Full Cabinet Enclosure

- Oiler = Auto Oiler

- Blade Guide = Precision Tungsten Carbide

- Wheel Dims. = 2” x 36”

- Wheel Cnstr. = Steel Construction

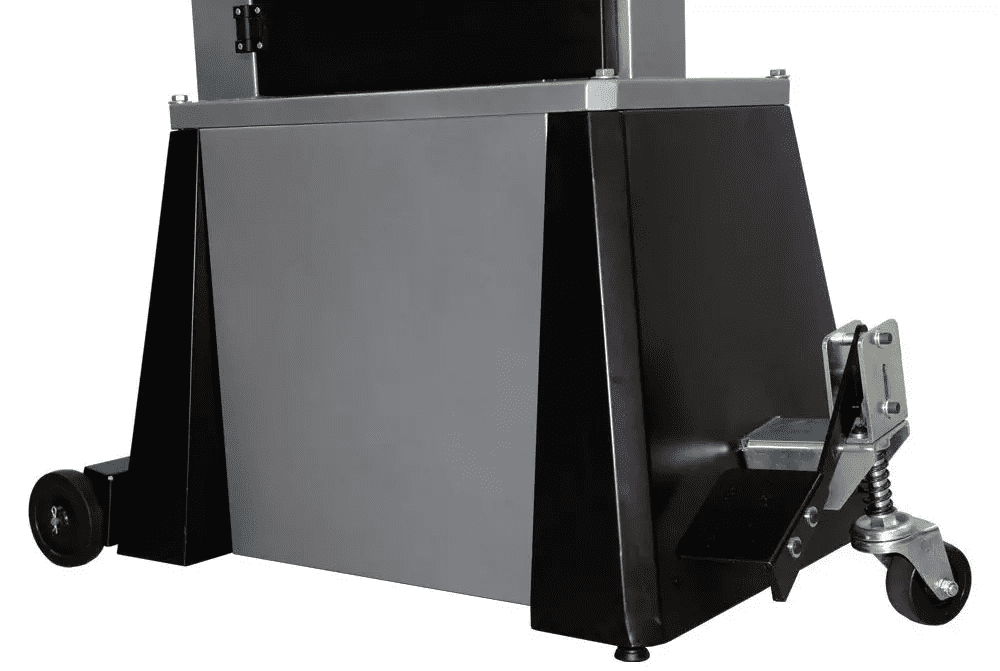

- Frame Const. = 1/4” Steel Construction

- Worktable Dims. = 16” x 85-1/2”

- Decible Rating = 76 dB

- Net Weight = 4321 Lbs.

- Gross Weight = 4762 Lbs.

- Machine Dims. = 107” x 87” x 91”

- Packaging Dims = 109” x 90” x 100”