Features:

- Maximum working size: 11-3/4” W x 11” H using hold-downs

- Minimum thickness of part: 3/16”

- Maximum cutting height: 11”

- 70 durometer (L) 216” x (W) 11-1/4”

- 3 Ply heavy duty industrial grade conveyor for long life

- Saw blade size: 1” or 1 ¼” x 168”

- Blade speed: 6850fpm

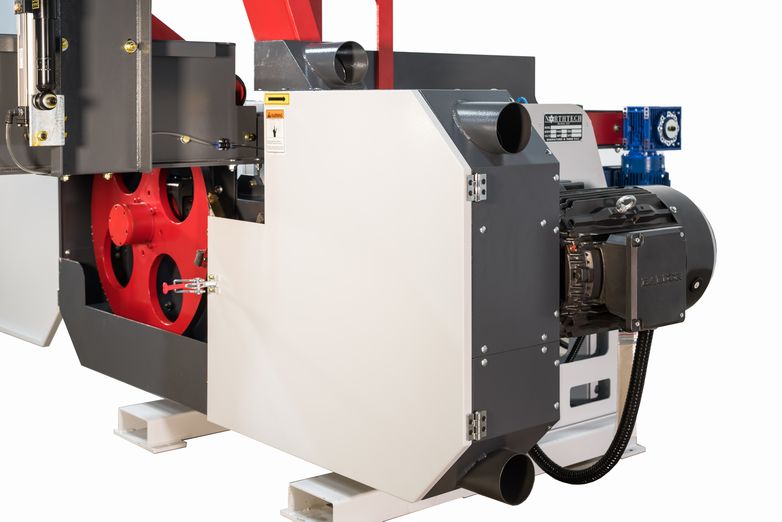

- Dual voltage 20HP Baldor motor is UL / CE approved

- 2HP feed motor

- VFD drive control of 0 – 97fpm is mated to a precision gearbox drive for optimum power delivery

- Frame is constructed of CNC machined steel

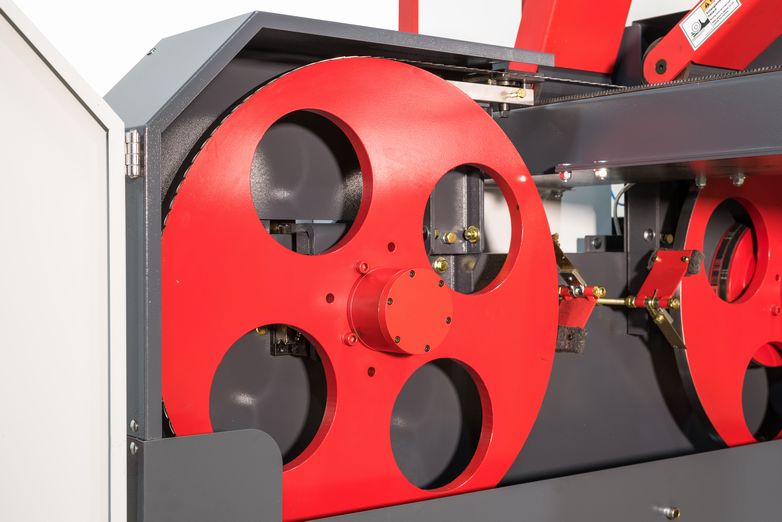

- 1” x 28” special heat-treated steel saw wheels, CNC ground, and balanced for vibration-free performance.

- (2) Oversized precision bearings on each saw wheel shaft ensure long term cutting accuracy

- (4) 4” dust ports requiring 436 CFM at each point of extraction

- A precision blade guide system with steel inserts ensures consistent quality of cut.

- Outside guide on a spring-tensioned lineal rail keeping guide next to each part

- Air cylinder tensioned infeed roller with heavy-duty spring control.

- Adjustable weighted outfeed roller securely holds part to the belt.

- Mechanical spring blade tensioning

- Electrical controls are neatly arranged into a dustproof cabinet

- Manual raise bed

- Machine dimensions (LxWxH) / Weight: 109” x 80” x 53” / 1,916lbs

- Machine Packing (LxWxH) / Weight: 87” x 46” x 45” / 1,690lbs

- Conveyor Table Packing (LxWxH) / Weight: 116” x 28” x 36” / 608lbs

- Tool box and (1) year parts warranty included

- Northtech offers a full line of dust collectors for any application.

- All machines are tested at our corporate headquarters in Indiana prior to shipment providing trouble-free start-up.

Specifications:

- Main Motor Hp. = 20 hp.

- Voltage/ Freq. = 208 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 70.3 Amps

- Feed Hp. = 2 Hp.

- Feed System = 11-1/4” Rubber Feed Mat

- Drive System = 2 Hp. Motor / Gear Box

- Feed Speed = 0 – 95 FPM

- Variable Speed = Inverter Controlled

- Elevation Style = Manual Crank Adjustment

- Elevation Sys. = Scirror Lift

- Total Hp. = 22 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 220V Control Voltage

- Operator Panel = Fixed

- Pass-Line = 35-3/8”

- Cut Envelope = 11-3/4” W x 11” H

- Min. Length = 12”

- Min. Width = 3/4”

- Max. Width = 11-3/4”

- Min. Thickness = 3/16″

- Max. Thickness = 11”

- Blade Size = 1” x 168”

- No. of Teeth = 192 Tooth

- Tooth Spacing = 7/8”

- Blade Kerf = 1mm

- Blade Speed = 6850 FPM

- Cleaning System = Scraper / Felt Pad

- Tracking Style = Manual Adjustment

- Tension Style = Manual Adjustment

- Vertical Travel = 4-5/8”

- Dust Collection = (4) 4” @ 1744 CFM

- Hold Down Style = Pneumatic / Gravity

- FLR Included = Filter, Lubricator, Regulater

- Recommended CFM = 1/4” Line @ 90 PSI

- Emergency Stop = Push Button

- Guarding = Full Cabinet Enclosure

- Oiler = Blade Oil Mister

- Fence Type = Fixed Fence

- Fence Dims. = 6-3/4” x 34-1/2”

- Blade Guide = Bearing Blade Guide

- Wheel Dims. = 1” x 28”

- Wheel Cnstr. = Steel Construction

- Frame Const. = Steel Construction

- Table Const. = Steel

- Decible Rating = 75 dB

- Net Weight = 1930 Lbs.

- Gross Weight = 2298 Lbs.

- Machine Dims. = 109” x 80” x 53”

- Packaging Dims = 2 Skids