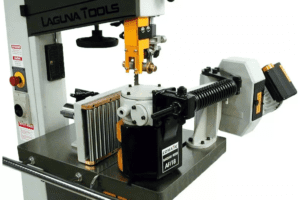

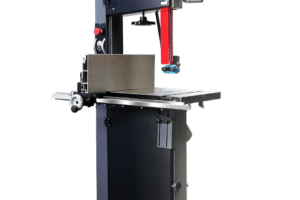

Advanced Features in Precision Resawing:

- Increased HP to 40 to meet higher production needs.

- 16 ¾’’ maximum part capacity.

- Digital set works (PLC) for fast and precise settings (accurate to .002″ automatic position).

- Precision German spring tensioning of the blade for constant tension to the band at 22,000 PSI.

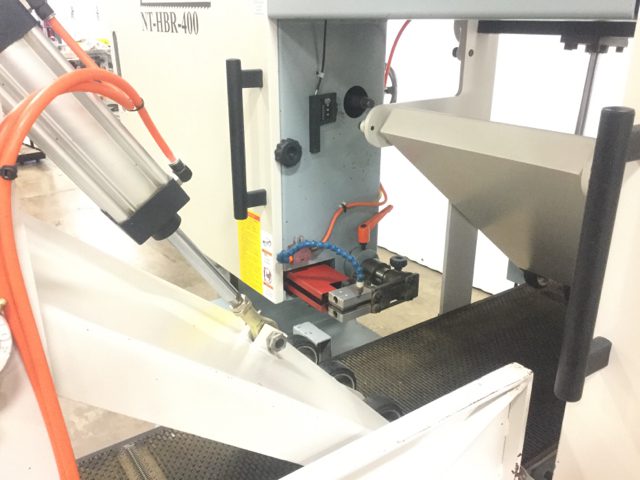

- Auto oil misting system improves blade life by up to 40 – 50% on many materials. (Only activated when the material is present by the sensor.)

- Pneumatic raise & lower of top feed rollers is automatic. When the material is presented, a sensor lifts and lowers onto the material on both sides of the blade. * Prevents material from slamming into the rollers and requires no adjustment within a 4″ ± thickness range. * i.e. random thickness material requires no adjustment.

- Remote and dustproof controls panel allows random placement, conveniently making the material placement and operator position a flexible option.

Specifications:

- Main Motor Hp. = 40 hp.

- Voltage/ Freq. = 460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 52.2 Amps

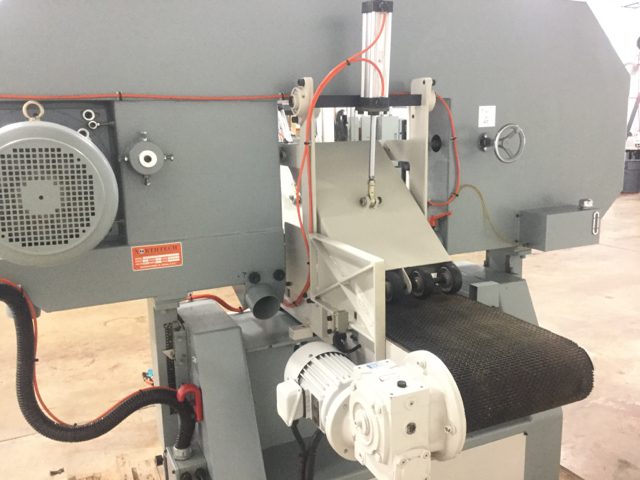

- Feed Hp. = 1.5 Hp.

- Feed System = 15-3/4” Feed Belt

- Drive System = Motor Mated to Gear Box

- Variable Speed = Inverter Controlled

- Elevation Hp. = 1.5 Hp.

- Elevation Style = CH-525 Elevation Control

- Elevation Sys. = (2) Post Jack Screw

- Total Hp. = 43.5 Hp.

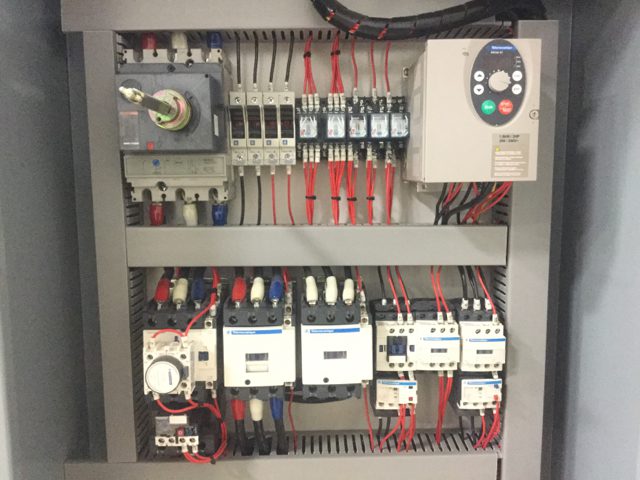

- Electronics = CE Approved Components

- Control Voltage = 220V Control Voltage

- Assisted Start = Wye-Delta

- Programmable = Elevation

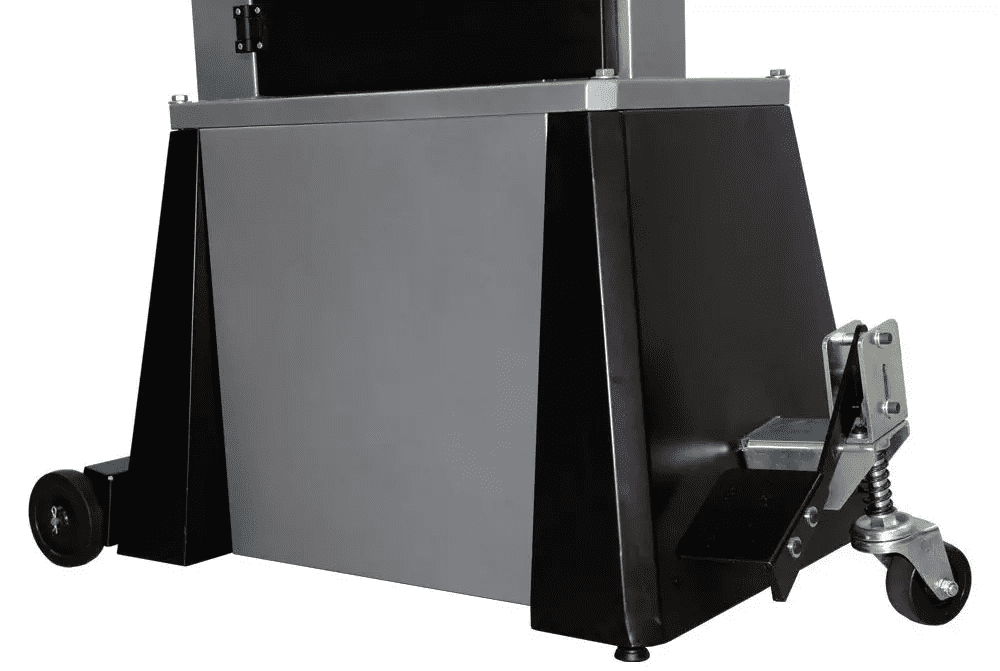

- Operator Panel = Mobile Cabinet

- Pass-Line = 40-3/8”

- Throat Capacity = 11-3/4” x 8”

- Min. Length = 30” Between Hold Downs

- Min. Width = 1-1/2”

- Max. Width = 16-3/4”

- Min. Thickness = 1/4”

- Max. Thickness = 17”

- Blade Speed = 6150 FPM

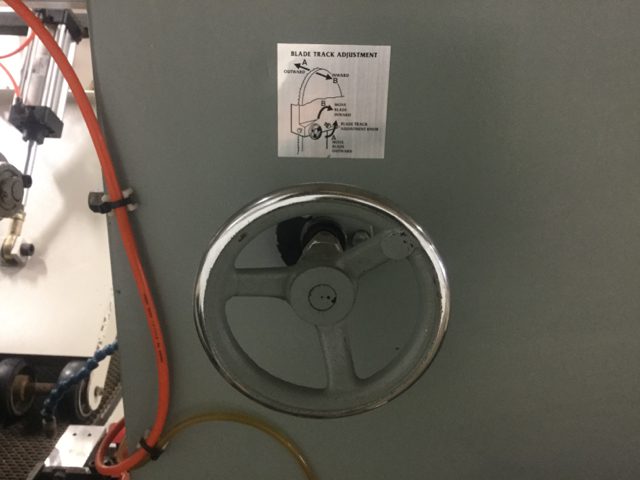

- Tracking Style = Manual Adjustment

- Tension Style = Manual Adjustment

- Vertical Travel = 10-3/8”

- Dust Collection = (2) 4” @ 900 CFM

- Digital Display = Elevation

- Hold Down Style = (1) Infeed (1) Outfeed Pneumat

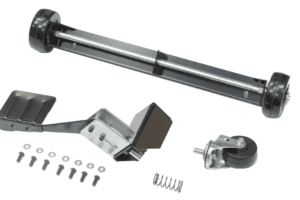

- FLR Included = Filter, Lubricator, Regulator

- Recommended CFM = 3/8” Supply Line @ 90 Psi

- Emergency Stop = Push Button

- Oiler = Blade Oil Mister

- Fence Type = Fixed Fence

- Fence Dims. = 8-1/2” x 18”

- Blade Guide = Steel Blade Guides

- Wheel Dims. = 1-7/8” x 31-1/2”

- Wheel Cnstr. = Steel Construction

- Frame Const. = 1/2” Steel Construction

- Infeed Table = 17” x 42-1/2”

- Net Weight = 4321 Lbs

- Gross Weight = 4761 Lbs.

- Machine Dims. = 104” x 125” x 90”

- Packaging Dims = 89” x 68” x 84”