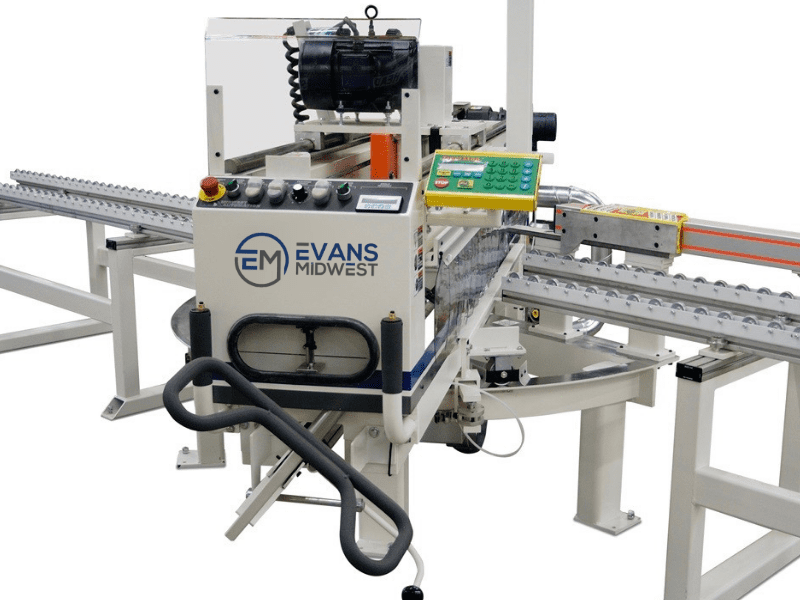

The Evans Midwest CS XLT Signature™ Cutting Station is designed with the same footprint as the CS XL but features an increased cutting height using a 20-inch (508 mm) diameter saw blade. This enhanced cutting capacity allows for a reduced overall cutting length of 50 inches (1360 mm) at a 90° angle of cut and 36 inches (915 mm) at a 45° angle of cut while increasing the maximum backsplash height to 6.875 inches (172 mm) from the bottom of the deck.

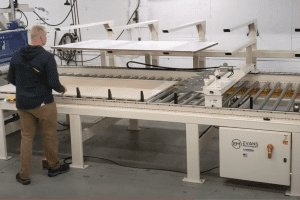

The Evans Midwest Cutting Stations have built a reputation for producing fast, accurate, and precise miter cuts and drawbolt mortises when fabricating postformed kitchen countertops. A single operator can complete a miter joint with drawbolt mortises in under three minutes with the SC XLT countertop saw, significantly reducing handling time, operator fatigue, and product damage.

With over 50 years of experience, Evans Midwest continues to set the industry standard, consistently improving product design as technology advances. The CS XLT Signature™ Cutting Station is available in both CS XL and XLT models, ensuring access to a high-quality machine backed by decades of expertise.

Standard Features:

- Upper and lower frames are machined in a single setup at Midwest’s state-of-the-art manufacturing facility

- Fixed stops at 22.5°, 45°, and 90° (RH & LH side}

- Pneumatic locking pin

- 5 HP saw motor with heavy-duty arbor assembly

- Variable speed forward/reverse drive

- The router system includes four(4) router motors, a guiding template, a rotating template pin with ball bearing

- Two (2) pneumatic hold-down clamps per side

- OSHA-recognized Safety Awareness Barriers

- Heavy-duty rear fence

- Three (3) dust collection hookups

- Plexiglass shield

- Ergonomically designed with low profile control panel and sure-grip operator handles

- Twenty (20) inch (508 mm) saw blade and four (4) router bits

- Safety interlocks and emergency stop

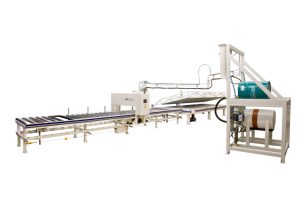

Optional Equipment:

- Standard And Heavy-duty Roller Conveyors

- Special Wheel Conveyors

- Special Fences With Nip-over Stops

- Tigerstop Electronic Fence With Automatic Positioning

- Laser Guideline Kit

- Dust Manifold

- Variable Miter Kit With Digital Readout

- Backsplash Clamps

- Support Rings For Short Parts

- Dust Enclosure Kit

- 5th Router Motor Kit

Evans Midwest Cutting Stations are fabricated, welded, machined, assembled, and tested at Evans Midwest 45,000 square foot manufacturing facility in Minneapolis, Minnesota, using the latest machining and fabrication equipment technology.

This allows Midwest to control the entire process, from ordering raw materials to shipping the machines, ensuring the highest quality standards are met.:

King Pin & Bearing Assembly:

Large diameter kingpin and precision bearing mounted in a machined pocket ensures stability as it rotates on the lower frame.

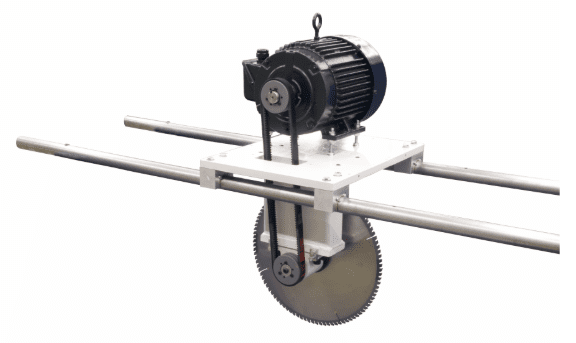

Saw Carriage:

Mounted on turned, ground, and polished rails and bronze bearings for years of dependable service.

Arbor Assembly:

Heavy-duty arbor assembly with two (2) precision ball bearings supported by a machined cast iron housing, pre-assembled and bench-tested to ensure vibration-free operation.

Lower Frame Weldment:

Top surface machined flat to +/-0.005 for smooth operation

Rear Fence:

The front edge is machined straight to +/-0.0025 to ensure cutting accuracy

Mazak CNC Vertical Mill:

Upper and lower frames are machined in a single setup to maintain the highest tolerances