AC 3120 Features:

- Heavy-duty frame with additional cross support beams to reduce flexing

- Rigid rear fence assembly with large-diameter jack screws and seven (7) contact points

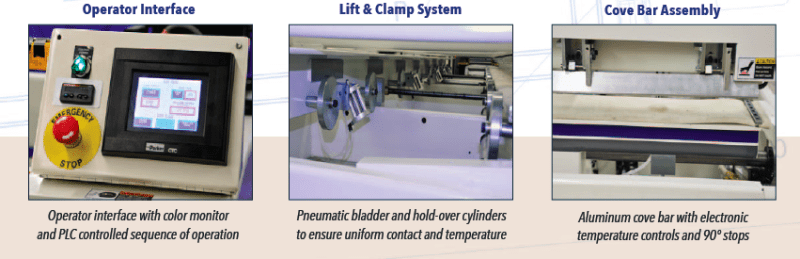

- Pneumatic lift and clamp system with air bladder and hold over cylinders to ensure countertop contact with rear fence and cove bar assembly

- Aluminum cove bar assembly with electronic temperature controls

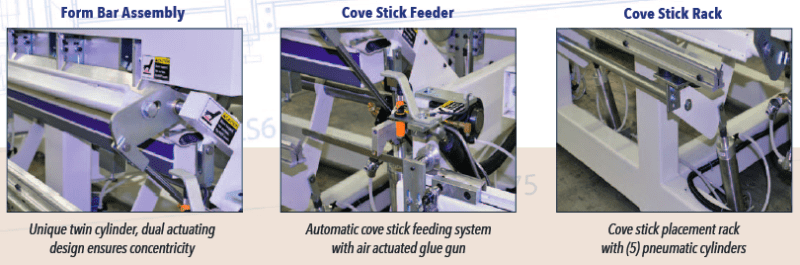

- Automatic cove stick system with electronic linear actuator pusher and variable speed control

- Cove stick placement rack with five (5) pneumatic cylinders

- Nordson Durablue™ Hot Melt System air-actuated glue gun and manifold

- Automatic form bar assembly with unique twin-cylinder, dual-actuating design ensures concentricity

- Ten (10) 90° stops

- Electronically controlled with adjustment

- Operator interface (HMI) with PLC-controlled sequence of operation

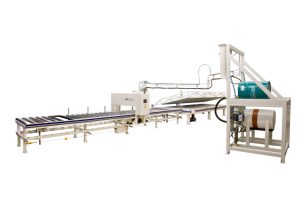

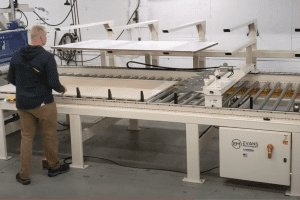

- Special infeed and outfeed conveyors

- Optional automatic load/unload system

[featured_box pos=”left” img=”https://360degreemachinery.com/wp-content/uploads/2021/05/Evans-Midwest-Logo-EM-270×270-1.jpeg” img_width=”” link=”https://360degreemachinery.com/product-category/new-machines/evans-midwest-countertop-machinery/”]

The Evans Midwest family of AutoCove™ Machines is uniquely designed to postform the inside radius of a kitchen countertop or vanity top with a covered backsplash, in high-volume production environments. The key to producing a quality backsplash is a rigid frame and rear fence, uniform contact of the countertop to the heating element, and a concentric forming bar to prevent stretching. The AutoCove™ Coving machine is designed to meet these specific objectives. Midwest machines have been used extensively in the kitchen countertop industries for over 50 years. Evans Midwest helps you laminate better, increase productivity, and improve quality.

[/featured_box]