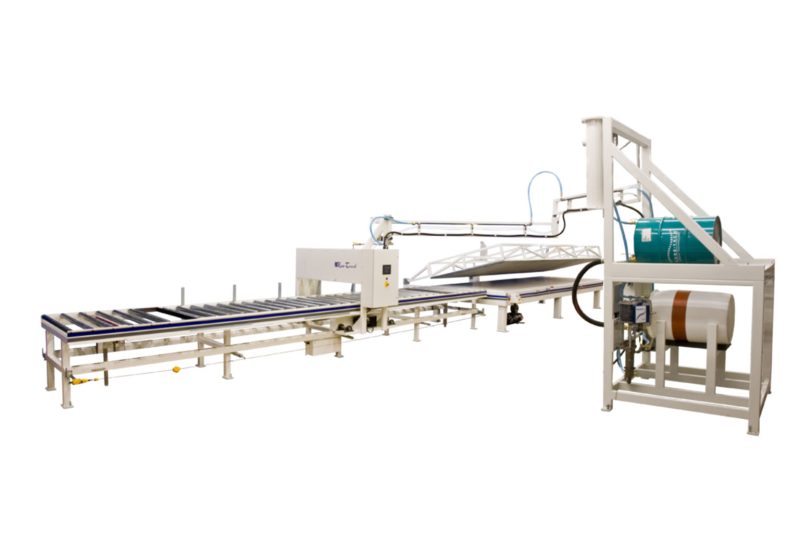

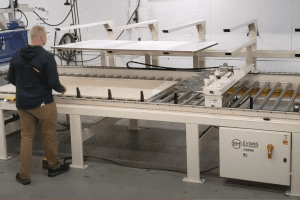

Discover the BE 418T 4′ X 8′ SIP Laminating System by Evans Midwest, an advanced laminating system specially designed to dispense one-part, moisture-cure polyurethane adhesives for materials that are not compatible with a roll coating process. This system has been meticulously designed as a structural adhesive for laminating oriented strand board (OSB) to expanded polystyrene (EPS) cores, making it perfect for use in structural insulated panel (SIP) construction.

Features:

- A bulk adhesive stand with a day barrel

- Zenith BE 418T traversing gantry with a water spray system

- An on-board electrical enclosure with PLC-controlled sequence of operation

- Operator interface (HMI) with a color monitor

- A heavy-duty transport conveyor with power rollers and stainless steel drip pans

- VP 418C vacuum press(es) with Busch™ vacuum pumps

- Capable of handling a maximum panel size of 4 ft X 8 ft (2.4 X 7.3 m)

Benefits:

Building with SIP panels has numerous benefits, including the conservation of natural resources, healthier indoor living environments, energy efficiency, solid and lasting durability, and significant savings in construction time and money.

Options:

The BE 418T 4′ X 8′ SIP Laminating System is available with Eco-Track, Acu-Track, or Xtreme-Track dispensing heads. Evans Midwest is dedicated to helping you laminate better, increase productivity, and improve quality, offering you a top-quality laminating system backed by years of expertise.

[featured_box pos=”left” img=”https://360degreemachinery.com/wp-content/uploads/2021/05/Evans-Midwest-Logo-EM-270×270-1.jpeg” img_width=”” link=”https://360degreemachinery.com/product-category/new-machines/evans-midwest-countertop-machinery/”]

Evans Midwest and strategic partner OMMA offer the widest variety of water-based laminating solutions in the world today. Whether you require a simple 2-roller glue spreader with a single cold pinch roll press for laminating high-pressure laminates or a very precise 4-roller glue spreader embedded in an automated system, Evans Midwest has the machinery to meet your requirements.

Evans Midwest Machines have been used extensively in the kitchen countertop, office furniture, architectural woodwork, and store fixture industries.

Bottom line: Evans Midwest helps you laminate better, increase productivity, and improve quality!

[/featured_box]