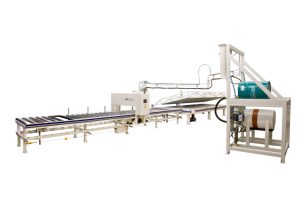

The Taylor Automatic Conveyor-Type Glue Applicator is available in lengths from 16’ to 60’.The felt roll model is designed for use with PVA type adhesives. It is equipped with a stainless steel glue pan, doctor roll, and outfeed cross bars. The glue roll is felt covered to provide even glue spread and is quickly removed for easy cleaning.

The length of the Glue Applicator depends on the loading area of the Clamp Carrier. For instance, an 8 1/2’ wide Clamp Carrier is usually equipped with a 16’ (8’ infeed, 8’ outfeed) Glue Applicator. Conversely, a 14-1/2’ Clamp Carrier is usually equipped with a 28’ (14’ infeed, 14’ outfeed) Glue Applicator. The width of the Glue Applicator depends on the thickness of the panel. Generally, 3/4 and 4/4 stock only require a 13’ wide glue roll. Thicker material, 5/4, 6/4 and above, require our 26″ or 39″ machines.

To produce the best Glue Applicator on the market, we have concentrated our efforts in three key areas:

- Precise and adjustable glue spread: The Taylor Glue Applicator is equipped with a fully adjustable live doctor roll. The doctor roll spins in the opposite direction (from the glue roll) which provides a controllable even spread. Thumbscrews and locking nuts are used to independently adjust both ends of the doctor roll.

With each machine, Taylor provides a wet film thickness gauge for measuring glue thickness. More importantly, it is our Live Doctor Roll design that allows each customer to fine tune the spread to their specifications. - Easy and fast clean up: We have equipped the Glue Applicator with a nightly storage system to save glue and clean up time. The glue pan cover fits tightly over the top of the glue pan and a large sponge is fitted to the roof of the cover. When soaked with water, the sponge keeps the cavity of air moist and prevents skimming of the glue during the night. During weekends and vacations, the glue pan and glue roll should be removed and cleaned. This job is completed quickly because the glue pan drops out with the removal of two pins. The glue roll slides out of the top of the Glue Applicator for cleaning

- Durability: The machine is designed with components which stand up to the rigors of a high production gluing operation. In addition, an adjustable safety clutch protects the conveyor chain against damage when careless operation results in wood jamming in the conveyor. This feature reduces down time and is self-healing so the machine returns to normal function once the jammed stock is removed

- Daily: The Conveyorized Glue Applicator is equipped with a stainless steel glue pan cover. Our system seals the glue area and keeps the glue roll moist. Nightly storage of adhesive minimizes clean up time and extends production time 1/2 hour per machine per day.

- Weekend: The Taylor system again minimizes clean up. The Applicator features a removable glue roll. The glue pan and roll are easily removed, cleaned and replaced, ready for production the following week.