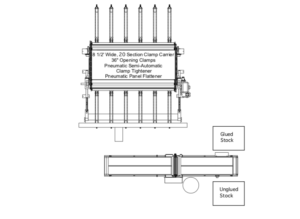

The Swing Style Clamp Tightener is the most economical system. The push button controls provide easy and rapid tightening and loosening of the clamps. The carriages ride on an overhead beam. Clamp pressure is fully adjustable up to 3,000 lbs. per clamp. Engagement is smooth and easy. The Flattener operation is also push button and pressures are adjustable. The two units are moved to the left or right side of the machine when rotating to the next row of clamps. The front rest is manual and the rotation is pneumatic.

(This system is only available in a pneumatic version.)

The Taylor Panel Flattener is designed to hold the stock flat while each clamp is tightened. The flattener rides on ball bearings on an overhead beam and is activated by a 3” air cylinder and is interlocked with the Semi-Automatic Tightener for a rapid safe operation. The flattener stays energized until the operator lifts up on the lever. At 90 psi, the downward force on the stock exceeds 625 lbs. which produces high quality flat panels.

Operation of a Gluing Cell

- Glue is applied with a Converyorized Glue Applicator

- The Operator places the material in the clamps and aligns the edges with glue on them

- The Clamp Tightener and Panel Flattener are used to tighten the clamps and flatten the material

- When all of the clamps are tight, the operator can index the machine to the next section by using the joystick valve

- the clamp tightener is used to loosen all of the clamps, and the cured panels or laminations are removed

- The loading procedure is then repeated

Typical end users:

Custom Cabinet Door Shop

Architectural Moulding and Millwork

Custom Stair Components

Smaller Furniture Manufacturer