Production is based on cycle time and panel size. Assuming that each section is curing 3 panels whose dimensions are 24″ x 24″ (60cm x 60cm) and assuming a cycle time of 2 minutes, production per shift equals:

One Panel:

=4 ft2 (.36M2)

One Section:

=12 ft2 (1.1M2)

One Cycle:

=2 minutes

=30 cycles/hour

=210 cycles/shift

Production output:

=12 ft2 x 210 cycles or 2520 ft2/shift

=1.1 M2 x 210 cycles or 231 M2/shift

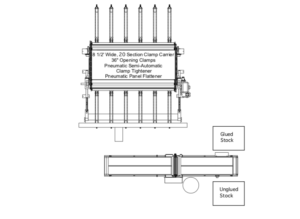

Semi Automatic Clamp Tightener:

- The Semi Automatic Clamp Tightener provides rapid and uniform clamping force up to 3,000 lbs (at 90 psi) on each clamp.

- The Tightener is offered in either Pneumatic or Hydraulic. It uses a motor, which provides a more uniform pressure that an impact type of Tool.

- The Semi Automatic Tightener’s ergonomic design reduces operator effort and increases productivity. The tightener carriage rides on ball bearings for quick and easy positioning to clamp on the front rest. A simple push or pull of the lever allows the Tightener to engage the clamp for tightening or loosening.

Pneumatic Panel Flattener:

- The Taylor Panel Flattener is designed to hold stock flat while each clamp is tightened

- The Flattener rides on ball bearings on an overhead beam and is energized by a push button. The push button to energize the cylinder is interlocked with the Semi Auto Tightener for a rapid and safe operation. The Flattener will stay energized until the operator pushed the button to release pressure.

- At 90 psi, the downward force on the stock exceeds 625 lbs, which produces high quality and flat panels.

Motor Drive for Rotation of the Sections:

- The motor drive rotates the Clamp Carrier from section to section. It is offered with a pneumatic or hydraulic (shown) motor. The Motor Drive worm gear reducer insures controlled indexing from section to section, even when rotating an unbalanced load. The Motor Drive is controlled by a Joystick, on the Front Rest of the machine, and can rotate forward or reverse. The Motor Drive speeds rotation of the machine with precise control and minimizes operator fatigue.

- Glue is applied with a Converyorized Glue Applicator

- The Operator places the material in the clamps and aligns the edges with glue on them

- The Clamp Tightener and Panel Flattener are used to tighten the clamps and flatten the material

- When all of the clamps are tight, the operator can index the machine to the next section by using the joystick valve

- the clamp tightener is used to loosen all of the clamps, and the cured panels or laminations are removed

- The loading procedure is then repeated