- Return on Investment: With our competitive pricing, the payback period is very fast. The cost of a new machine is typically less than one year’s wages.

- Quality and Innovation: Taylor’s 105 years in business and our four Challenger Awards assures a U.S.-made machine high on quality and long on innovation

- Fast Delivery and Easy Setup: All machines are built in our Upstate New York factory in eight weeks or less. Every machine is fully assembled here and ships 80-90% assembled. You will be up and running in hours

- Sales and Support: Because we design, build, test and ship at one facility, we understand the needs of the customer. Year in and year out, we are regarded as one of the best sales support companies in the woodworking industry

When you buy a Taylor Return Conveyor, you buy more than a machine, you buy into a company that partners with you to make your company productive. Cameron Automation is a division of James L. Taylor which has served the woodworking industry for over 100 years. In that time, we have developed and maintained a level of customer service and products that are second to none.

Our machines are American made. From where Terry unloads raw steel from trucks to where Monty packs a completed machine for shipping, it’s all done here in the US. We maintain a large inventory of parts ready for next day delivery. We support our customers with an available and knowledgeable service staff. Our service is second to none. Just ask any of our thousands of satisfied customers

|

Base Model

|

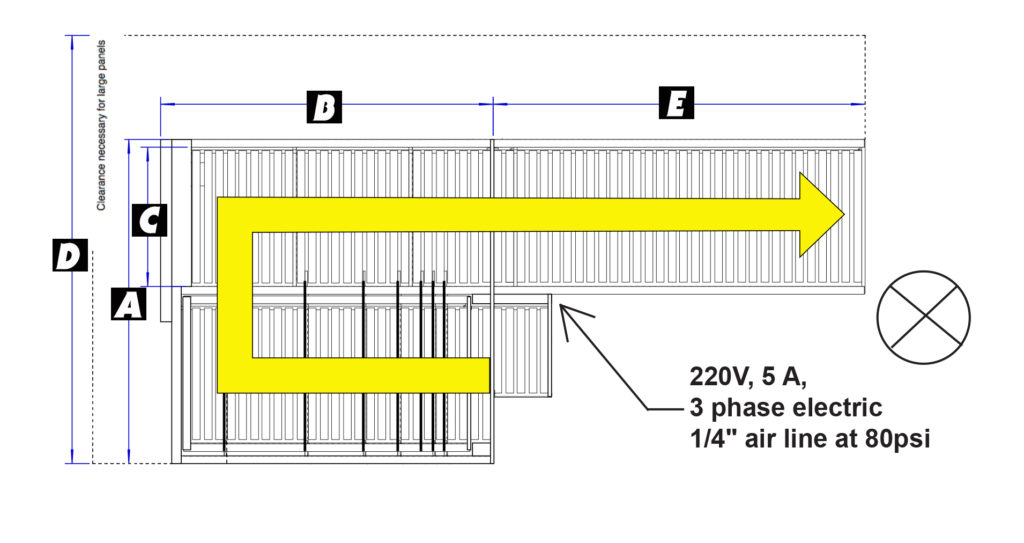

A | B | C | D | E |

| #38A-24C-24R-5L Model

24” Wide Receiving Rollers and 24” Wide Return Rollers Returns Panels up to 36” Wide and 60” Long |

60″ | 62″ | 24″ | 64″ | Any |

| #38A-36C-36R-5L Model

36” Wide Receiving Rollers and 36” Wide Return Rollers Returns Panels up to 50” Wide and 60” Long |

84″ | 62″ | 36″ | 112″ | Any |

| #38A-36C-36R-7L Model

36” Wide Receiving Rollers and 36” Wide Return Rollers Returns Panels up to 50” Wide and 84” Long |

84″ | 74″ | 36″ | 112″ | Any |

| #38A-36C-36R-8L Model

36” Wide Receiving Rollers and 36” Wide Return Rollers Returns Panels up to 50” Wide and 96” Long |

84″ | 86″ | 36″ | 112″ | Any |

- Components exit your edgebander, sander, or rip saw

- Our catch is equipped with powered rollers which feed the component completely onto the catch section

- A sensor is used to activate cylinder and lower the catch and place the component onto traverse belts

- Traverse belts carry the component sideways onto the return section

- The return is equipped with powered rollers to start the component back to the operator

- The return extension carries the component back to the infeed end