Features & Benefits:

- Simple Mechanical Design: Ensures reliability and ease of maintenance.

- Foot Pedal Actuation: Improves operational safety and efficiency.

- Honeycomb Pattern Grid: Applies the perfect amount of glue evenly across materials.

- No Nightly Clean Up: Anodizing process preserves the glue overnight without cleanup.

- Versatile Size Options: Available in multiple sizes to suit various production scales.

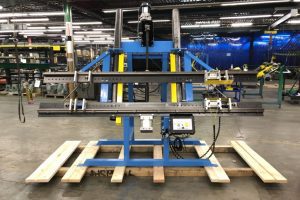

Efficient Design for Every Use

The Taylor (JLT) #138B Glue Plate Spreader streamlines the glue application process. It features a foot pedal operation that lowers the glue pan for even adhesive application. Its mechanical design is tailored for ease of use and durability, making it ideal for repetitive tasks in small- to medium-sized production environments.

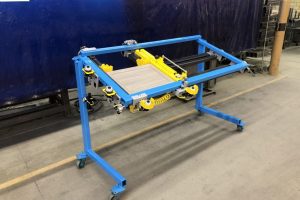

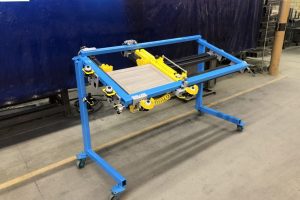

Innovative Glue Application System

This spreader uses a honeycomb pattern grid to apply an even coat of glue across various materials. The foot pedal activation allows for hands-free operation, increasing safety and efficiency on the production floor.

Maintenance-Free Operation

One of the standout features of the #138B is its no nightly cleanup requirement. The machine’s components are designed to submerge back into the glue, preserving the glue’s condition overnight through an anodizing process. This feature saves time and reduces waste, enhancing overall productivity.

Versatility Across Sizes

Available in multiple sizes, the #138B can accommodate different scales of production needs, from 6 to 20-section clamp carriers. This versatility makes it suitable for various businesses, including furniture makers and cabinet producers, ensuring it meets diverse operational demands.