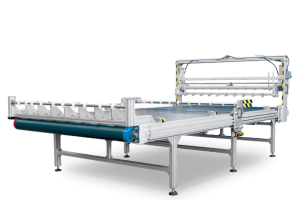

The S2R two roller gluer is without doubt a good starting point for those applying glue by roller for the first time. Easy to use, simple to clean at the end of each shift and suitable for small and medium-sized businesses, this unit can also work in an automatic line when fitted with the required accessories.

The standard version includes two applicator rollers and respective glue regulation reservoirs.

Single drive with chain transmission, fixed speed of 18 metres/min, protection guards inside the structure in zinc-coated sheet steel, as also the washing water collection tanks.

185 mm diameter spreader rollers, which can be ground and lined up to three/four times before being rubber-coated again, thanks to the thickness of the rubber coating and the hardness of the materials used.

Roller lining can be customised according to the type of production envisaged.

The working width ranges from 400 mm up to 1600 mm with a reinforced structure and a 1 HP drive. We can also design units outside our 800 mm/1400 mm standard range.

Optional accessories: forward speed adjustment with a mechanical variable-speed drive or a 1:5 ratio electronic inverter,

automatic top roller lift to adjust the thickness, with digital monitor position reading, support-mounted castors with locking brake, track wheels for working inline, manual or automatic roller washing systems, stainless steel parts such as the glue regulation reservoirs, collection tanks, etc.

Internally perforated rollers, connection to heat conditioner, possibility of glue feed using our ACM 11 and CLT-A Mixer.