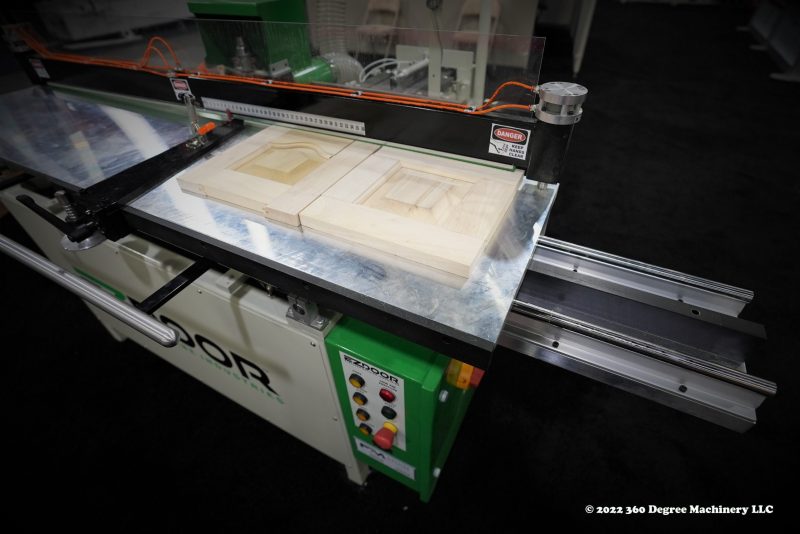

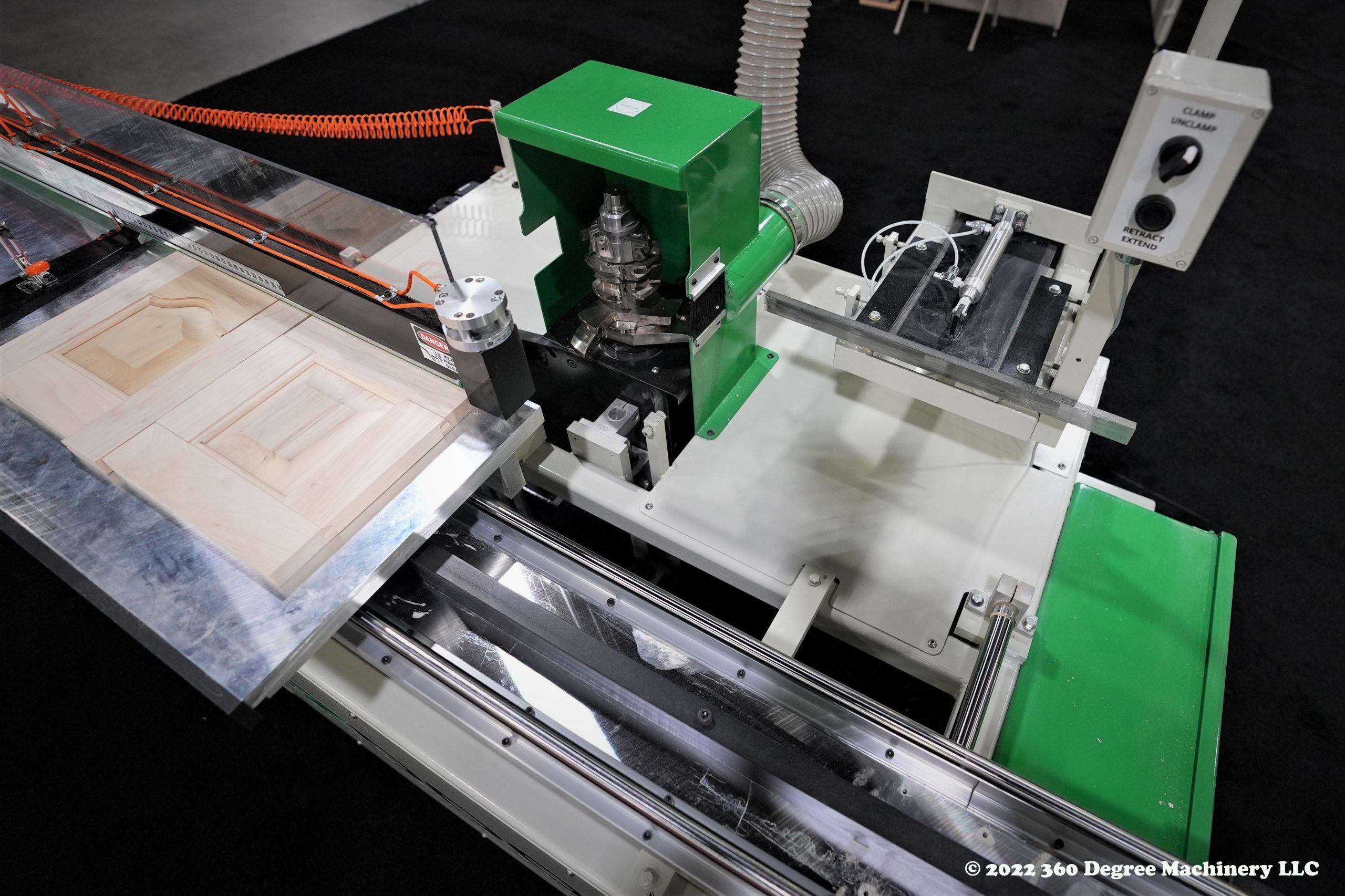

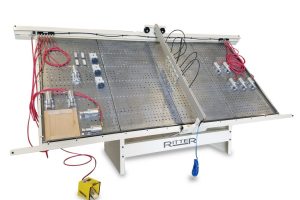

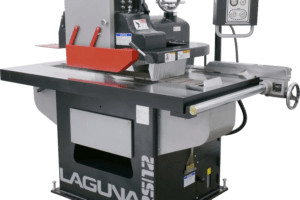

Fletcher EZ Door Machine Overview

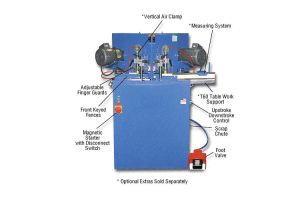

The Fletcher EZ Door Machine is engineered to meet the demands of cabinet shop owners and woodworking professionals who require precision, speed, and safety in their production processes. Specifically designed for crafting high-quality raised panel cabinet doors, this machine combines cutting-edge features with robust construction to deliver exceptional performance in woodworking environments.

Efficient Door Production

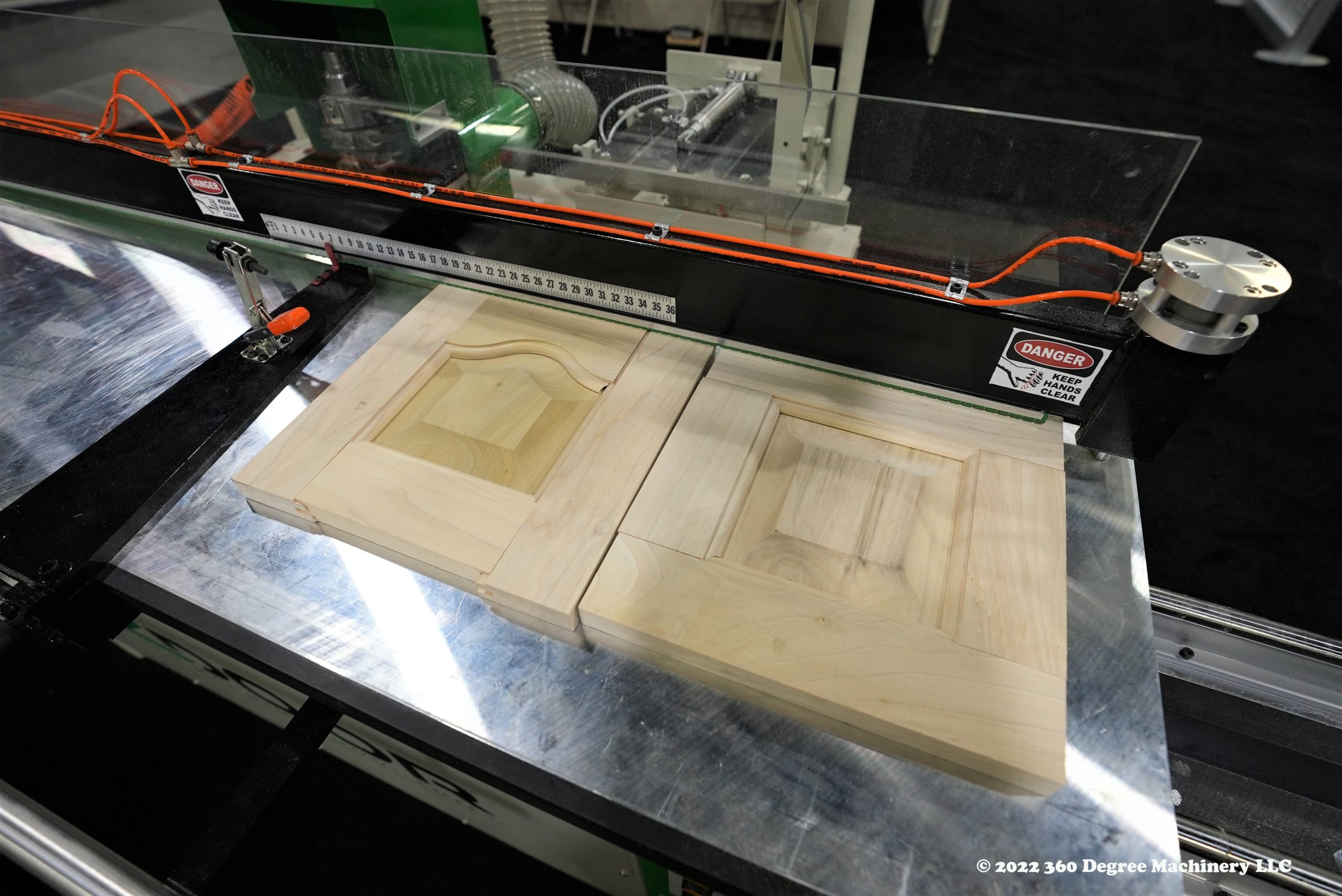

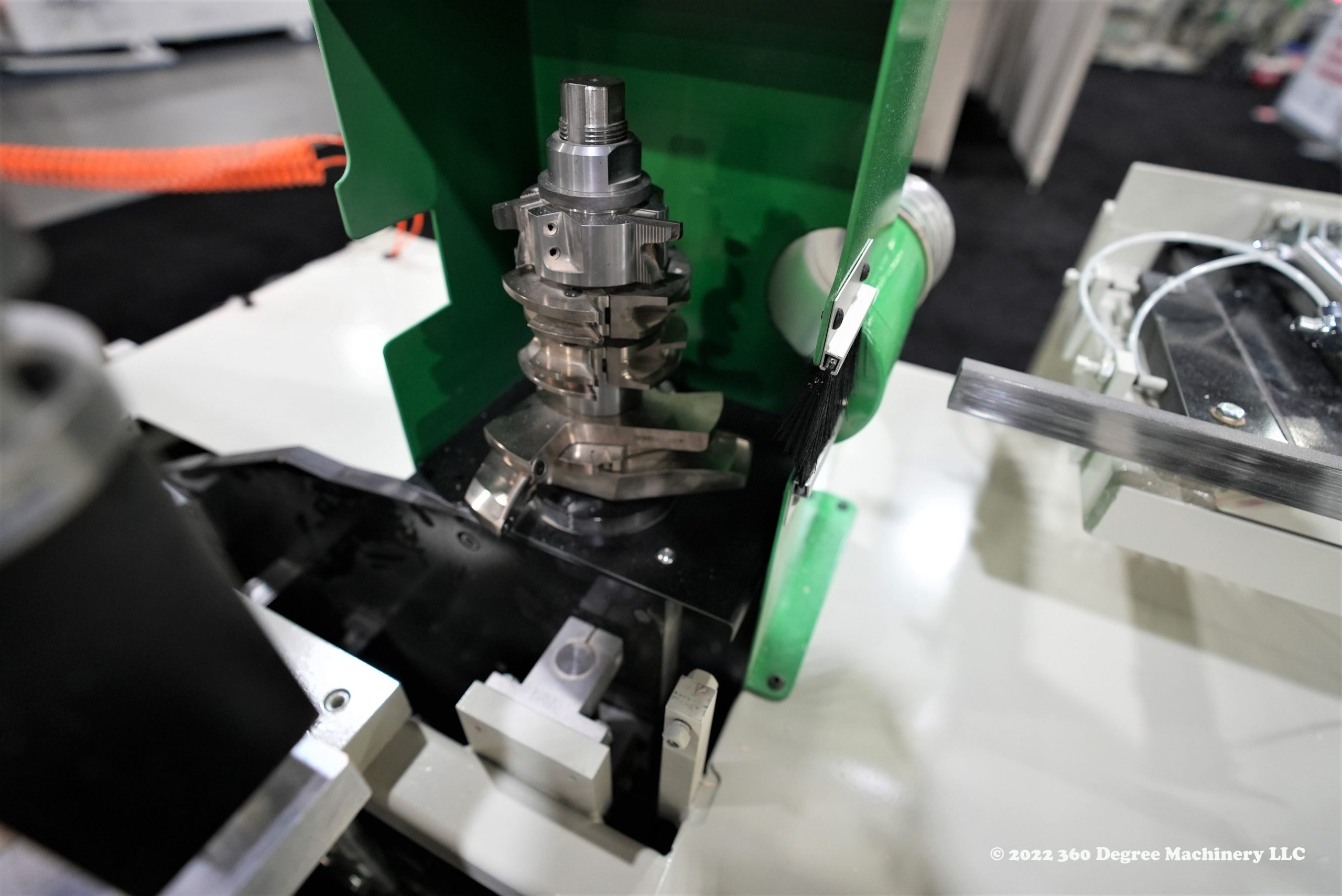

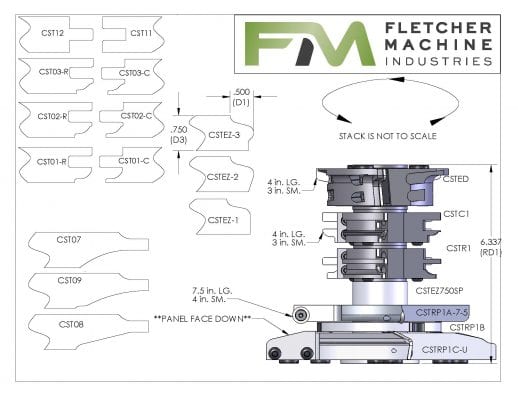

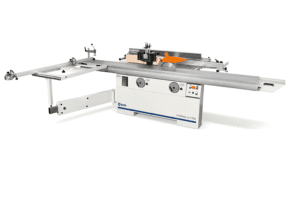

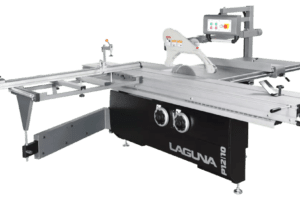

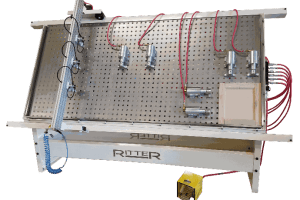

The standout feature of the Fletcher EZ Door Machine is its button-operated four-position spindle, which allows for seamless transitions between cutting tasks. Whether you’re shaping rails, stiles, panels, or outside edges, the single-button selection system repositions insert blades and material stops quickly, minimizing downtime and boosting productivity.

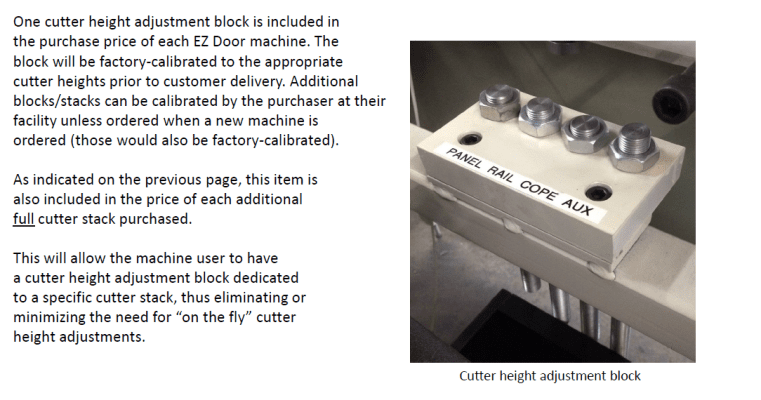

- Quick-Change Cutter Height Adjustment: Eliminate the hassle of manual adjustments with a pre-calibrated block that adapts to each cutter stack, saving time on every job.

- Versatile Cutting Capabilities: Create square or arched doors, including mullions for glass panels, with ease—perfect for custom cabinetry projects.

Durable Construction

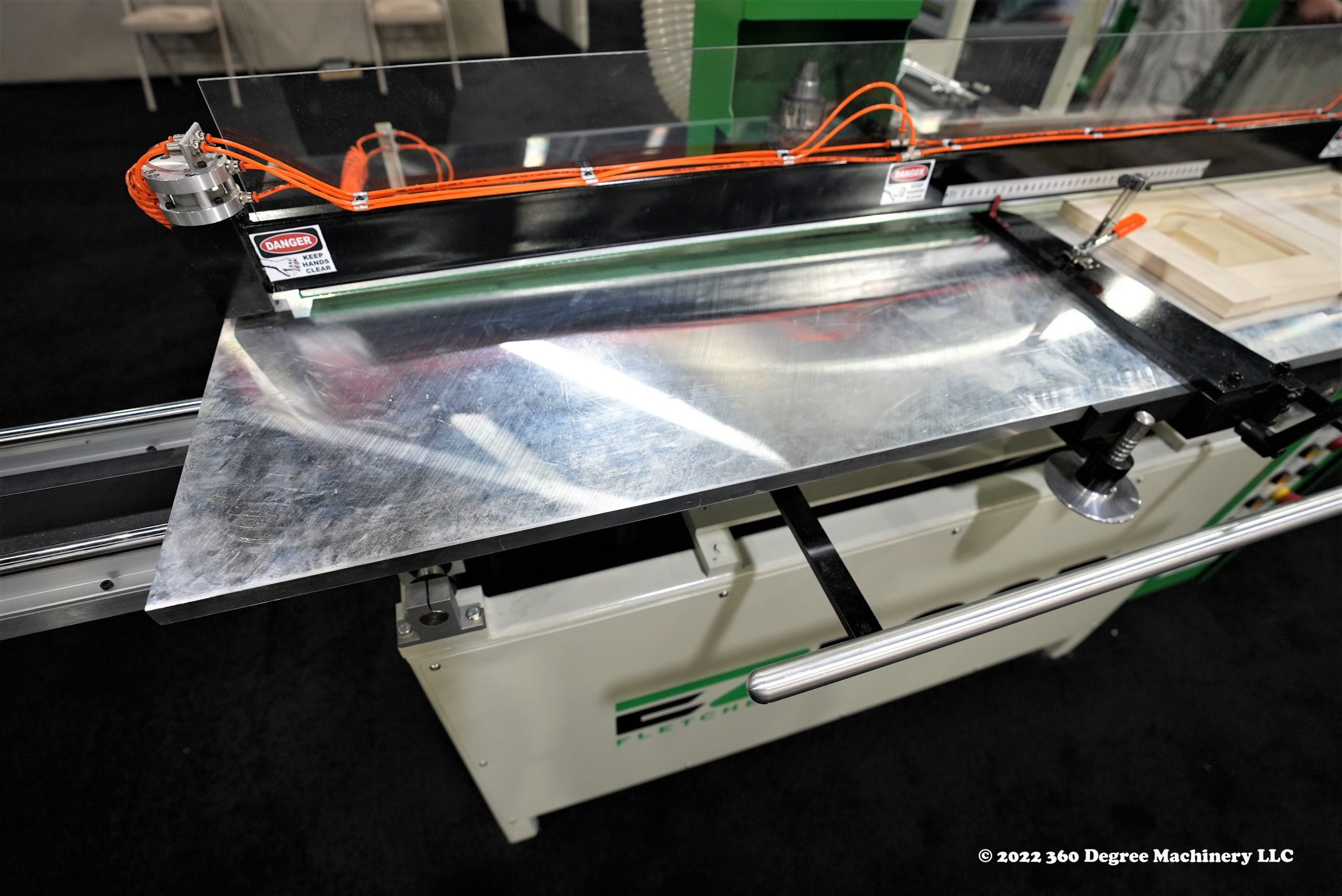

Constructed with 2-inch heavy wall steel tube framing, the Fletcher EZ Door Machine is built to endure the toughest workloads. Its sturdy design ensures long-term reliability and stability, making it a valuable addition to any professional woodworking shop.

- Heavy-Duty Build: Engineered to handle daily use without compromising performance.

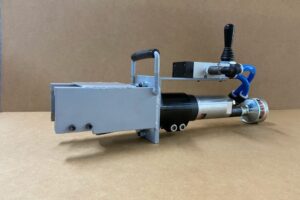

- Precision Components: Features a rigid lubricated spindle assembly and recirculating ball bearing slides for smooth, accurate cuts.

User-Friendly Operation

Designed with safety and simplicity in mind, the Fletcher EZ Door Machine is easy to operate and maintain, even for woodworkers with minimal experience.

- Pneumatic Clamping Fence: Keeps hands safely away from cutters, enhancing operator safety.

- PLC-Controlled Pneumatics: Delivers repeatable stops and precise control, free from dust or chip interference.

- Intuitive Design: Quick to learn, allowing your team to maximize productivity with minimal training.

Applications

The Fletcher EZ Door Machine excels in:

- High-volume cabinet door production for busy shops.

- Custom woodworking projects requiring precision and flexibility.

- Businesses aiming to improve efficiency and safety standards.

Why Choose the Fletcher EZ Door Machine?

- Speed: Craft a complete 5-piece door in minutes, accelerating your workflow.

- Safety: Prioritizes operator protection with thoughtful design features.

- Customization: Adapts to various door styles using a quick-change template system.

- Reliability: Built tough to withstand demanding production schedules.

Specifications*

| Specification | Value |

|---|---|

| Spindle Size | 1-1/4″ diameter with 6″ capacity |

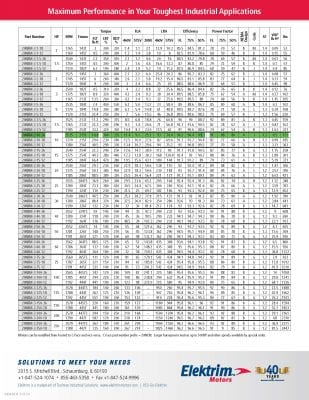

| Motor Power | 10 HP, 6,500 RPM |

| Table Travel Length | 62″ |

| Maximum Cut Length | 59″ for rails, 55″ for panels |

| Maximum Material Thickness | 1″ |

| Maximum Arch Width | 24-1/2″ for standard templates |

| Maximum Arch Height | 7/8″ to 2″ for standard templates |

| Minimum Rail Material Width | 1-1/2″ plus depth of cut |

| Positions on Spindle | 4 |

| Selection | Single button for rail/stile, cope, panel, and outside edge |

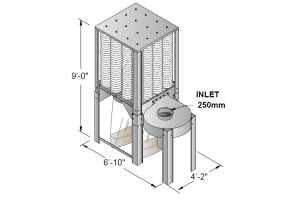

| Dust Extraction | (1) 4″ diameter outlet (392 CFM) |

| Air Requirements | Minimum 70 PSI |

| Electrical Requirements | 20 full load amps @ 230 volt 3-phase |

| Machine Footprint | 41″ x 96″ |

| Floorspace Required | 48″ x 129″ |

| Machine Weight | 1,250 lbs |

Contact 360 Degree Machinery

Elevate your cabinet door production with the Fletcher EZ Door Machine. Contact 360 Degree Machinery today to explore how this innovative tool can transform your woodworking business. Call us at 630-229-6705 for more details, a demo, or to place your order.

*The EZ-Door machine can be customized per your specifications. Call or email us to learn more. Specifications are subject to change.

Door Tooling (one stack/set included/Brand: Hi Definition Tooling/note”: most profiles fit same heads with a few exceptions):

Motor Specifications: