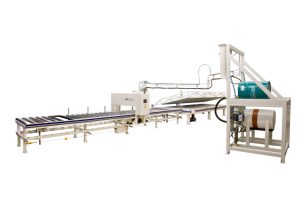

The Taylor Laser Opti-Sizer is a computerized panel selection machine which is used with a Conveyorized Glue Applicator system. The Opti-Sizer saves both material and labor when compared with either sizing panels by hand or at the straight line rip saw.

The Opti-Sizer automatically selects random width (3/4″ to 6″) parallel ripped boards to produce panels of a specified width, thus eliminating manual board selection. The Opti-Sizer will consistently size panels within 1/8″ at a rate of up to 7 panels per minute.

Random width stock is then placed into the infeed slots of the Opti-Sizer. Laser sensor is used to read the height of random width boards on edge in the slots on the Opti-Sizer. These values are fed into a computer. Based on the desired panel width, the computer rapidly calculates and evaluates the thousands of combinations of board selection. When the solution is found it advances those boards selected onto the Conveyorized Glue Applicator. After a batch of boards has been sent onto the Conveyorized Glue Applicator, if a usable combination of measured boards is still left in the Opti-Sizer, another panel will be sent out before scanning again.

| Material | Machine Size |

|---|---|

| For 4/4 – 5/4 | 13 Slot & 21 Slot |

| For 4/4 – 6/4 | 11 Slot & 18 Slot |

| For 4/4 – 8/4 | 15 Slot

|

- Fast Sizing Operation

- Tallies Panels, Boards, & Board Feet

- Reliable Accuracy

- Delivers Boards to the Glue Applicator

- Available in Various Sizes: 11 to 21 Slots, 6′ to 9′ Lengths

- Upgrade available for older models