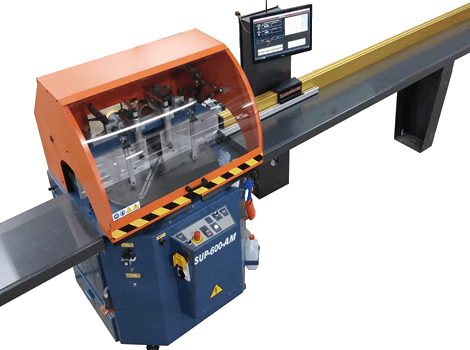

AngleMaster Computerized Miter Saw Features:

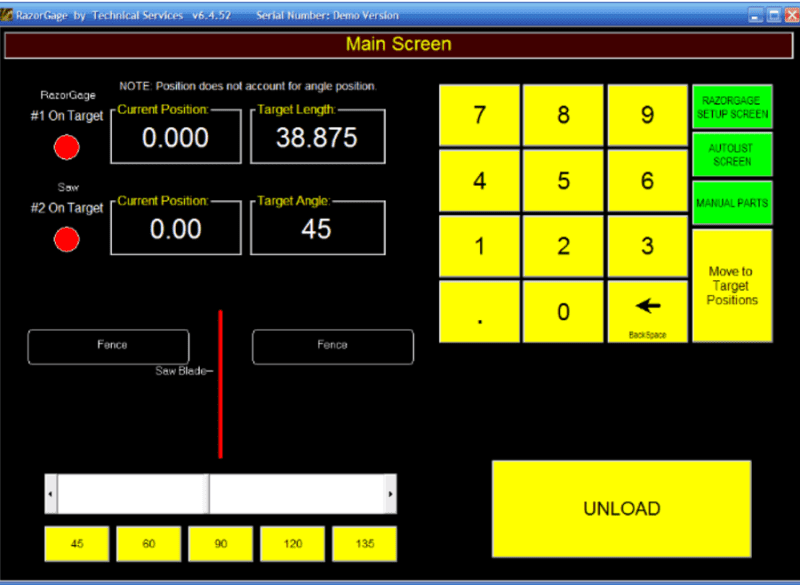

- Windows Tower PC operation on a large, color touch-screen monitor

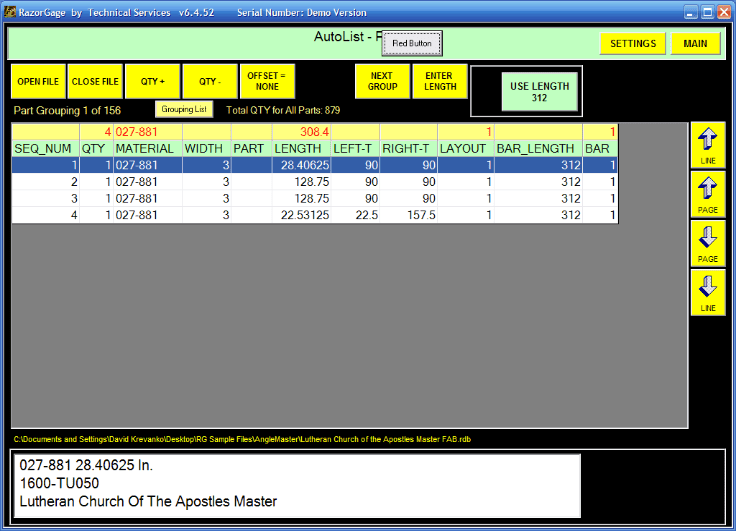

- Download cutlists directly to the RazorGage AngleMaster computer via Wi-Fi or wired Ethernet cable

- Store thousands of cutlists on the computerized miter saw software. Optimize and sort cutlists into thousands of groups according to various criteria

- Label printer option available

- AngleMaster Angle Saw System comes with a PVC tabletop, but optional steel or PVC rollers are available

- Optional articulated pusher mounted gripper

- Blade mist lubrication standard for cutting aluminum

Using the AngleMaster Semi-Automatic Miter Saw:

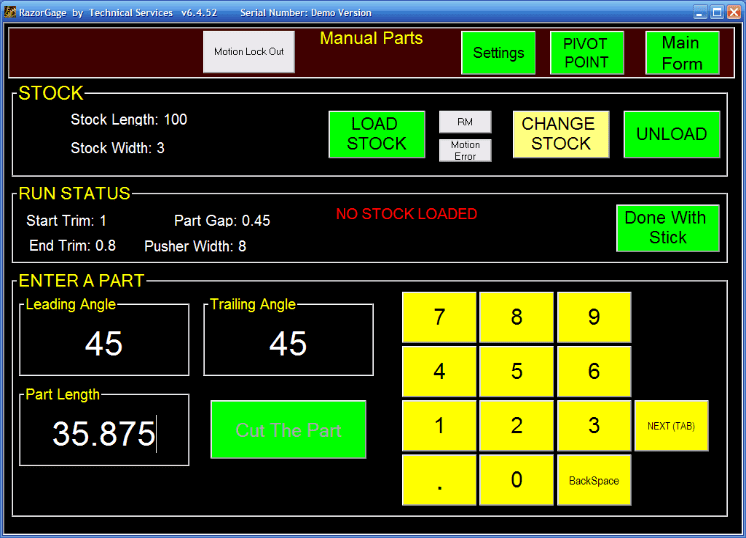

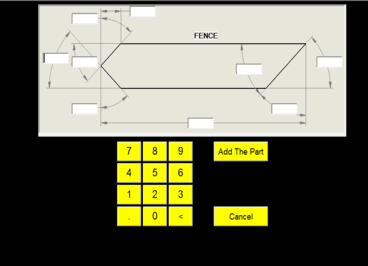

The operator selects a cutlist from those downloaded from the office or manually enters the leading and trailing angles, length, & width, required for a single part. The RazorGage positioner advances the material and rotates the saw to the correct leading angle. The operator makes sure the clamps are adjusted correctly, cycles the saw, clears any small jam-prone drops from the table, and clicks DONE on the touch screen. The RazorGage positioner then advances the material and rotates the saw to make the trailing edge cut. Once the positioning of material and blade is complete, the operator makes sure the material is against the fence and the pusher, engages the clamps, and cycles the saw. Repeat the process.

At RazorGage, safety is the top priority. To use the AngleMaster computerized miter saw, the operator must clear each cut part and drop before the machine will advance the material for the next cut. Using the touch screen interface to control the AngleMaster is simple and intuitive. Other safety features include the two-hand anti-tie-down buttons. After ensuring that the clamps are not in the path of the saw blade and the blade has automatically rotated to the proper angle, the operator uses the two-hand anti-tie down buttons to cycle the saw. This unique safety feature protects operators and prevents potential accidents.

RazorGage provides free two-day installation and training with the purchase of all AngleMaster automatic miter saw systems (US or Canada only) to get your new AngleMaster up and running quickly, safely, and efficiently so you can start enjoying its features.

[row ]

[col span=”1/2″ ]

Specifications:

- Accurate angles from 22º to 160º

- 5.5 HP 3000 rpm 230 or 460Vac 3ɸ (Must Specify)

- Stock Capacities up to 56 feet.

- Push Force: 200 lb at 10 inches per second.

- Max Speed: 40 inches per second.

- Dust Collection: 2 x 4” Diameter Port; 600 CFM

- Compressed Air Required: 80~120 psi; 5 CFM

- Blade: 600mm Diameter x 132 Tooth; 50mm arbor

- Coolant Tank W/Mist Lubrication & 1 Gal Coolant

- Blade Wrench

- Air Hose

- 2 Horizontal & 2 Vertical Pneumatic Clamps

- Adjustable Feed Rate on Saw Head

- Dual Palm Buttons

- Blade Door Interlock and Hood Interlock Switches

[/col]

[col span=”1/2″ ]

Cut Capacity:

- 7” Round Tube at 90°

- 6” Round Tube at 45°

- 4” Round Solid at 90°

- 4.75” Round Solid at 45°

- 6” Square Tube at 90°

- 4.75” Square Tube at 45°

- 11.75” x 5” Rectangular Tube at 90°

- 5.75” x 4.75” at 45°

[/col]

[/row]

[featured_box title=”” pos=”left” img=”https://360degreemachinery.com/wp-content/uploads/2021/03/Built-in-The-USA.png” img_width=”120″ link=””]

The RazorGage Product Line is manufactured in Ames, Iowa, USA, by Technical Services, Incorporated.

Technical Services, Inc. has been developing custom specialized machinery for more than 40 years that speeds and improves the manufacture of automotive components, recreational vehicles, appliances, windows, doors, cabinets, water testing products, and more. The RazorGage product line draws from those decades of widely varying experiences to bring to market the finest positioning system in its price range available today.

[/featured_box]