Production is based on cycle time and panel size. Assuming that each section is curing 3 panels whose dimensions are 24″ x 24″ (60cm x 60cm) and assuming a cycle time of 75 seconds, production per shift equals:

One Panel:

=4 ft^2 (.36 m^2)

One Section:

=12 ft^2 (1.1 m^2)

One Cycle:

=75 seconds

=48 cycles/hour

=384 cycles/shift

Production output:

=12 ft^2 x 320 cycles or 4608 ft^2/shift

=1.1 m^2 x 320 cycles or 422 m^2/shift

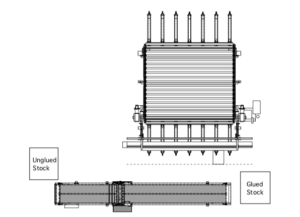

Automated Tightener / Flattener & Overhead Loosening System

The Taylor Automated Front End is designed to double the operators production (pictured above and left). The Taylor Super Automated front end Increases that already doubled production by another 20% by utilizing an overhead loosener (pictured above and to the right) that loosens the clamps a section ahead. Utilizing PLC software and sensors, the Tightener / Flattener will index across the series of clamps, and automatically engage, flatten, and tighten the clamps while the operator is organizing the next batch of material for the Glue Applicator. While this is happening, the loosener is working, up above, and loosening a section ahead. The software also has a “Sequencing Program” that allows you to set a distinct path for the Tightener setting an order of clamps to tighten that makes the most sense for your products. Adjustable tightening and flattening pressure make this machine the most versatile and efficient design in Taylors’ arsenal.

Motor Drive for Rotation of the Sections:

The motor drive rotates the Clamp Carrier from section to section. It is offered with a pneumatic or hydraulic (shown) motor. The Motor Drive worm gear reducer insures controlled indexing from section to section, even when rotating an unbalanced load. The Motor Drive is controlled by a Joystick, on the Front Rest of the machine, and can rotate forward or reverse. The Motor Drive speeds rotation of the machine with precise control and minimizes operator fatigue.

High End, American Made Hydraulic System

The Clamp Carrier hydraulic system incorporates a proportional valve controlled by the programmable controller. By using a series of sensors and inputs, the controller monitors and measures the traverse speed of the Clamp Tightener carriage, the rotational speed of the Clamp Tightener, and the speed of the Clamp Carrier rotation. These measurements are taken on every cycle during normal operation and speeds are automatically adjusted up or down without operator or maintenance intervention. This upgrade take a huge step towards a maintenance free machine

- The operator removes glued panels from one section of the Clamp Carrier and refills the section with stock taken from the out- feed of the Glue Applicator

- The operator adjusts the rear jaws of the clamps (if necessary), and presses the “Tighten” button on the control stand. The machine does all the rest

- All panels are flattened and clamps tightened automatically until the Tightener/ Flattener carriage comes to a stop at the end of the front rest. The front rest then slides out to provide clearance for the clamps, the Motor Drive indexes the Clamp Carrier to the next section of clamps, and the front rest returns. The Loosener carriage then traverses, stopping and loosening clamps that it finds along the way, while the operator repeats step 1