NT 10-1100PRP

• Working Width: 43″

• Planing Heads: (1) * 7″ (6) row helical 30 x 12x 1.5 mm insert cutter head

• Sanding Heads: (2) * (1) 10″ 70 durometer spiral fluted contact drum * (1) 3-1/4” Pad

• Sanding Belt Length: 103″

• Main Spindle Motor: 40HP/40HP/30HP

• Feed Motor: 5HP with Inverter

• Table Movement Motor (PLC Touch Screen): 1HP

• Brush Roller: (1) 1HP

• Configuration: Planer Head-Rubber Roller-Pad

• Size Of Sanding Belt: 43″ x 103″

• Feed Speed: 15 – 60 FPM

• Conveyor Speed Display: PLC Touch Screen

• Table Height 37″ / Table Lift 4.75″ by PLC Touch Screen

• (2) Oscillating Full Coverage Air Cleaners

• HZ & Voltage: 60HZ / 460V, 3PH

• Gross weight: 14000 lbs.

• Packing dimensions: 115″ x 79″ x 99″

- Machine Hp. = 117 hp.

- Voltage/ Freq. = 460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 136 Amps

- Configuration = Planer, Roller, Pad

- 1st Head = 40Hp. 7” Spiral Helical Head

- 2nd Head = 40 Hp. 10” Spiral Fluted Rubb

- 3rd Head = 30 Hp. 3-1/4” Pad

- Brush Motor Hp. = 1 Hp.

- Feed Hp. = 5 Hp.

- Feed System = 43” Rubber Feed Mat

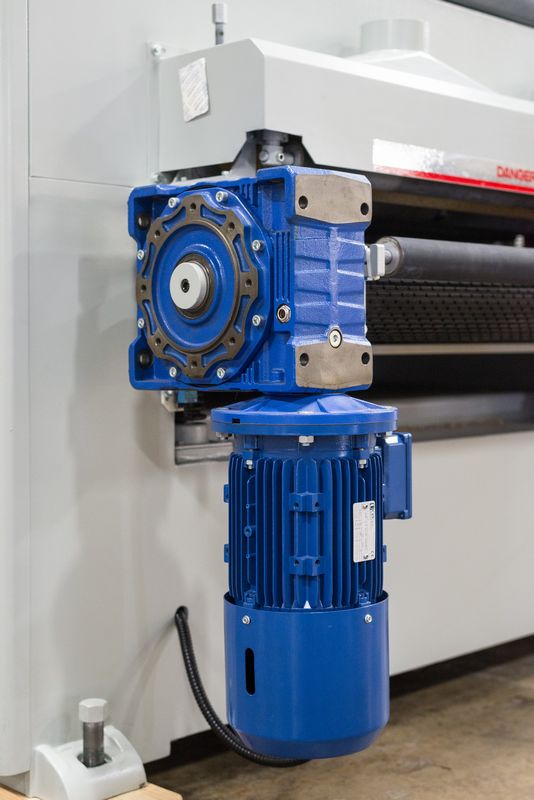

- Drive System = Gear Box Inverter Controlled

- Feed Speed = 15 – 60 FPM

- Variable Speed = Inverter Controlled

- Elevation Hp. = 1 Hp.

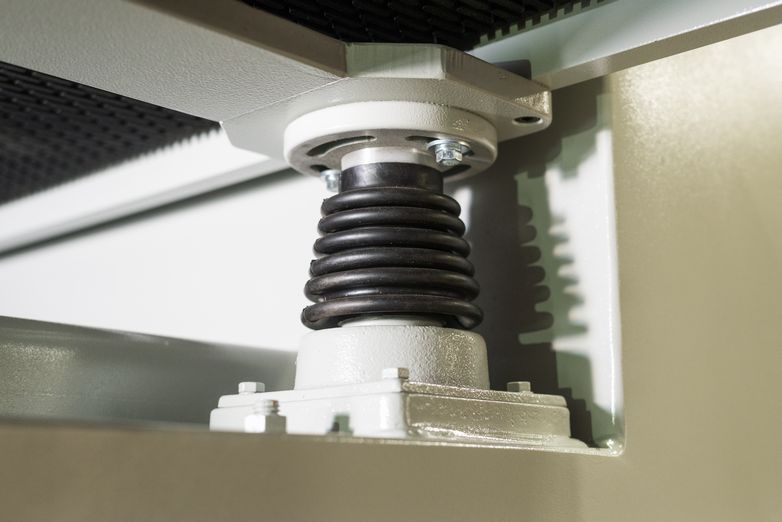

- Elevation Sys. = (4) Post Jack Screw

- Elevation Style = Auto Touch Screen Control

- Total Hp. = 117 Hp.

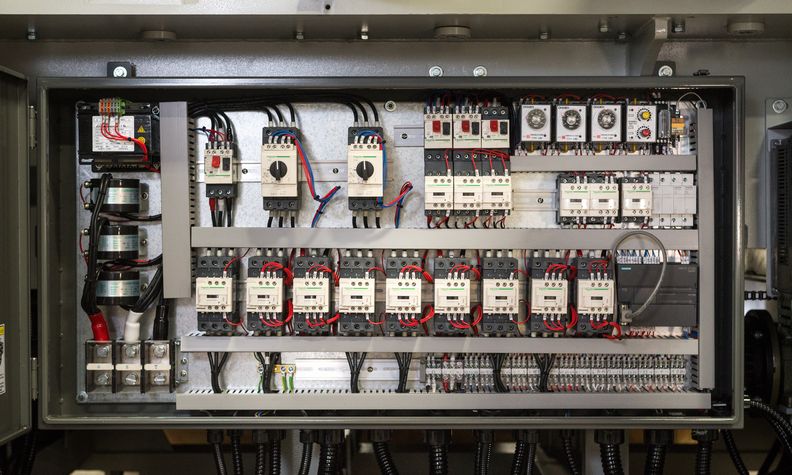

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 230 Volt

- Programmable = Elevation

- Touch Screen = 8” Digital Touch Screen

- Min. Length = 20”

- Max. Width = 43”

- Min. Thickness = .372”

- Max. Thickness = 4-3/4”

- Tooling = 30 x 12 x 1.5 mm

- Head Type = Dynamically Balanced Helical Head

- Cutter Head Dim = 7” x 44-1/4”

- Cut Head Matl. = Alloy Steel

- Rows of Cutters = 6 Rows

- No. of Inserts = 264

- Insert Size = 30 x 12 x 1.5 mm

- Sandpaper Size = 43” x 103”

- Platen Specs. = 4” x 44-1/2” with 8” Graphi

- 1st Belt Speed = 5000 FPM

- 2nd Belt Speed = 2700 FPM

- Oscillation Sty = Pneumatic Controlled

- Oscillation Rte = 20 Cycles/Minute

- Oscillation Trv = 1/2”

- Cleaning System = Oscillating Jet Blow Off

- Tracking Style = Pneumatic Dust Proof Eye

- Tension Style = Pneumatic

- Dust Collection = (13) 5” @ 8853 CFM

- Dust Port Out = 5”

- Digital Display = Touch Screen 8”

- Conveyor = Seamless

- Idle Rollers = (12) Hold Down Rollers

- Pressure Shoes = 9” 12” 10” 5-1/2” x 48”

- Hold Down Style = Spring Loaded Pressure Shoes

- Kickback Finger = (45) 1/4” Fingers

- Emergency Stop = (1) Push Putton (2) Bars

- Brake System = (3) Pneumatic Dual Caliper Dis

- Frame Const. = 1” Steel Construction

- Decible Rating = 78 dB

- Net Weight = 13228

- Gross Weight = 14000

- Machine Dims. = 104” x 74” x 92”

- Packaging Dims = 115” x 79” x 99”