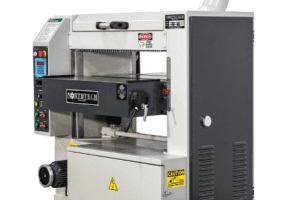

Cutter Heads:

- Cutterhead Motor: 25HP, 3PH 230/460 Volt

Features:

- Helical 4″ cutterhead provides a high chip removal rate, superior surface finish & low noise level (under 85 dba).

- A powerful 25 HP cutterhead motor and 2HP feed motor makes this planer ideal for heavy-duty planing and meets high production requirements. Arranged with Y-Delta soft start controls (Square D).

- The main motor is Nema-rated and standard with a 2-year warranty and service throughout North America.

- Digital positioning controller for convenient thickness setting (with memory control to 99 thickness settings).

- Variable feed speed is driven by a VFD and TECO inverter duty DC motor (0-90′ min) with an LED readout of feeding speed.

- Powered table elevation for fast and convenient thickness setting. The opening has been increased to 12″ on NT-660S series planers vs. 8″ on the standard NT-660 planers.

- Extra heavy, rib-reinforced cast iron table is surface precision ground. 660S-20HCVS has (4) precision 35mm jackscrews to support the planer’s rugged construction.

- Adjustable bed rollers ensure fast and proper positioning with regard to rough lumber to finished glue panels.

- UV rubber outfeed roller provides an optimum finish with reduced vibration.

- Corrugated sectional infeed roller has an independent yield for running strip stock of varying thicknesses without the danger of kickback.

- Anti-kickback fingers equipped at the infeed end provide added safety for the operator.

- Raising and lowering limit controls for powered table elevation

Specifications:

- Top Head Hp. = 25 Hp.

- Voltage/ Freq. = 230/460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 58/29 Amps

- Feed Hp. = 2 Hp.

- Feed System = (2) Segmented/(1) Rubber Roll

- Drive System = Belt

- Feed Speed = 5 – 75 FPM

- Variable Speed = Inverter Controlled

- Elevation Hp. = 1 Hp.

- Elevation Style = REC 727M Elevation Control

- Elevation Sys. = (4) Post Jack Screw

- Total Hp. = 28 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 110 Volt

- Programmable = REC 727M Elevation Control

- Min. Length = 10”

- Min. Width = 1”

- Max. Width = 26″

- Min. Thickness = 3/16″

- Max. Thickness = 12”

- Cutter Head RPM = 1800 Rpm

- Tooling = 15 x 15 x 2.5 mm

- Head Type = Dynamically Balanced Helical Head

- Cutter Head Dim = 4” x 26”

- Cut Head Matl. = Alloy Steel

- Rows of Cutters = 6 Rows

- No. of Inserts = 156 Inserts

- Insert Size = 15 x 15 x 2.5 mm

- Dust Collection = (1) 6” @ 981 CFM

- Digital Display = Elevation and Feed Speed

- Powered Rollers = (3) Top Powered Rollers

- Idle Rollers = (2) Idle Bed Rollers

- Pressure Shoes = 26” Spring Loaded Pressure

- Frame Const. = 1/4” Steel/Cast Iron Construc

- Decible Rating = 70 dB

- Net Weight = 2420 Lbs.

- Gross Weight = 2770 Lbs.

- Machine Dims. = 44” x 39” x 55”

- Packaging Dims = 52” x 51” x 55”