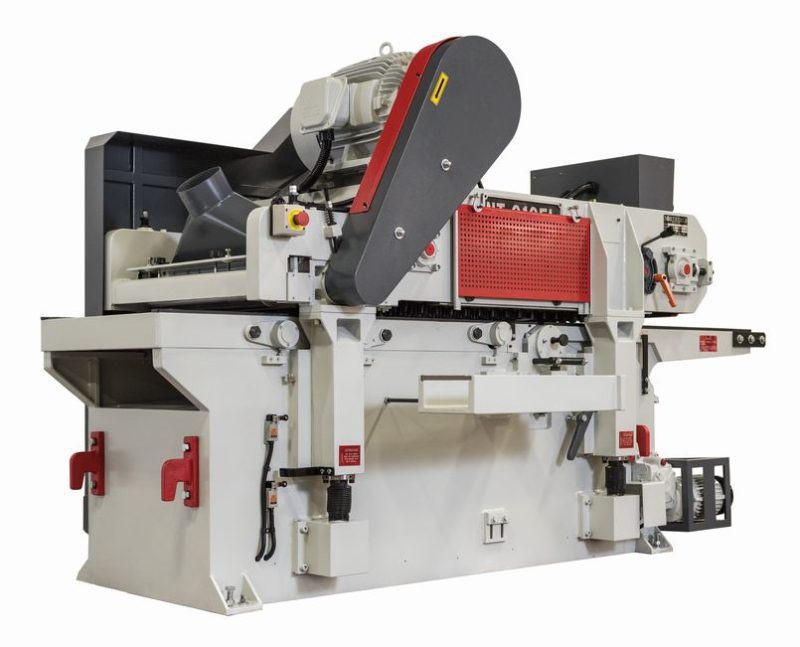

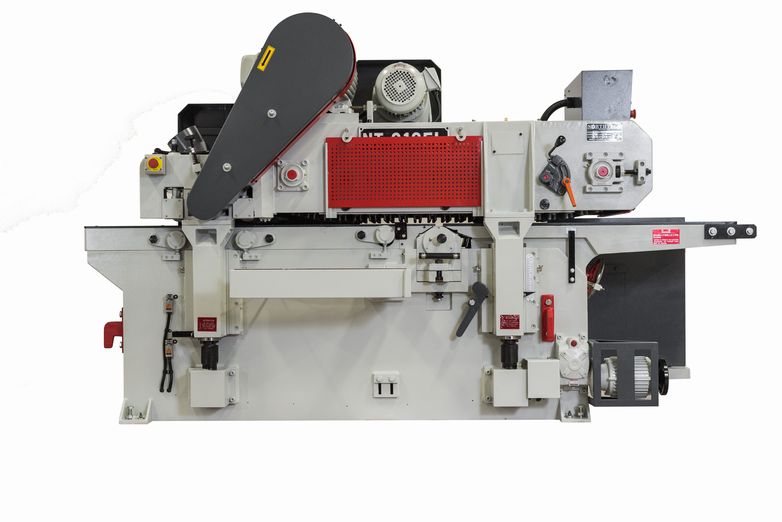

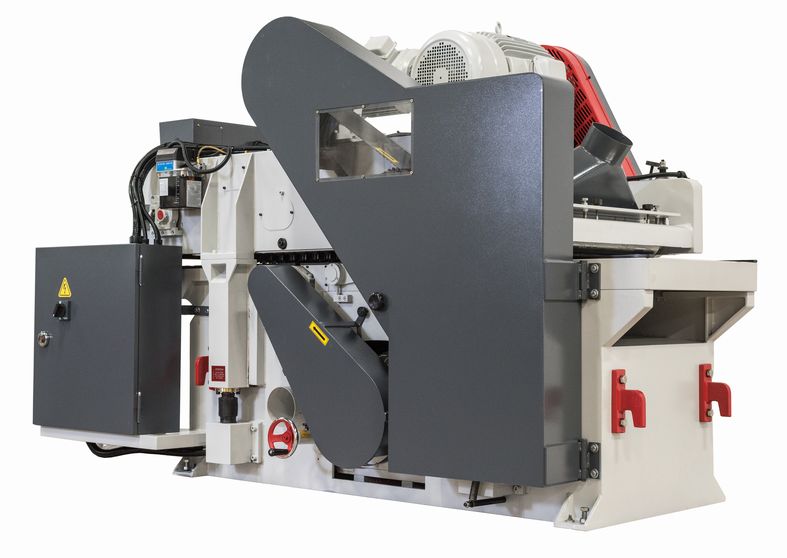

Cutter Heads:

- 30HP Top, 25HP Bottom

- Dual (6) Row Helical Cutterhead with double-sided 30 x 12 x 2.5mm inserts

- 5000 RPM solid steel cutter heads with Class 7 NSK bearings

- Cutterhead decibel rating of 75 dB or less

Product Dimensions:

- Working thickness 10 – 155mm (3/8” – 6-1/2”)

- 15” min working length

- 24” maximum width

Feed System:

- 5HP feed motor

- Carpet feeding spike system with 1100 spikes

- Feed speed 25 – 95 ft/min

Features:

- Mechanical variable speed

- Digital control panel with 3 amp meters

- Chrome bedplate .01mm (.004”) thick

- Amperage requirement: 230V @ 200AMP, 460V @ 100AMP

- (2) 6” dust ports requiring 1000 CFM @ each point of extraction

- Automatic lubricating system with low level shut off

- UL/CE Certified electrical components

- Includes operator’s manual and parts book

- Machine dimensions: 112” L x 46” W x 74” H

- Packing dimensions: 117”L x 52”W x 78”H

- Machine gross / net weight: 7,680 lbs. / 8,300 lbs

- One-year parts warranty

- All machines are tested stateside before shipment providing trouble-free start-up

Specifications:

- Top Head Hp. = 30 Hp.

- Bottom Head Hp. = 25 Hp.

- Voltage/ Freq. = 230/460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 175/87.5 Amps

- Feed Hp. = 5 Hp.

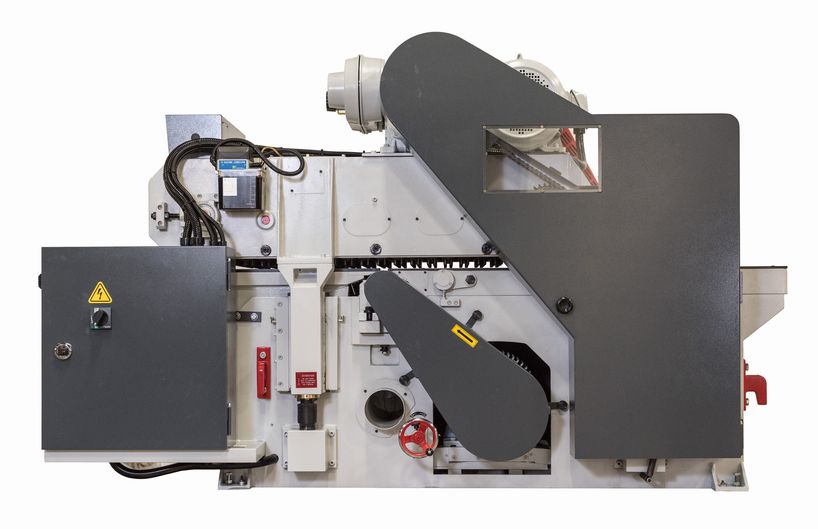

- Feed System = Carpet Feed / Powered Rollers

- Drive System = Chain with Slip Clutch

- Feed Speed = 25 – 95 FPM

- Variable Speed = CVT Adjustable Drive

- Elevation Hp. = 1 Hp.

- Elevation Style = DP-626S Elevation Control

- Elevation Sys. = (4) Gibbed Dovetail Slideways

- Total Hp. = 61 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 110 Volt

- Min. Length = 15”

- Min. Width = 1.5”

- Max. Width = 24”

- Min. Thickness = 3/8”

- Max. Thickness = 6-1/2”

- Cutter Head RPM = 5100 Rpm

- Tooling = 30 x 12 x 2.5 mm

- Head Type = Dynamically Balanced Helical Head

- Cutter Head Dim = 5-1/4” x 25”

- Cut Head Matl. = Alloy Steel

- Rows of Cutters = 6 Rows

- No. of Inserts = 105 Inserts

- Insert Size = 30 x 12 x 2.5 mm

- No. of Heads = 2

- Dust Collection = (2) 6” @ 1962 CFM

- Dust Port Out = (2) 6” Ports

- Digital Display = Elevation

- Powered Rollers = (4) Powered Rollers

- Idle Rollers = (1) Idle Roller

- Hold Down Style = Chip Breakers/ Pressure Plate

- No. of Spikes = 1100 Spikes

- Rear E Stop = Push Button

- Guarding = High Visibility Guarding

- Oiler = Auto Oiler

- Low Oil Warning = Low Oil Shut Off / Warning

- Frame Const. = 1/2” Steel/Cast Iron Construc

- Chrome Bed = .004” Chrome Plated Bed

- Decible Rating = 80 dB

- Machine Dims. = 112” x 46” x 74”

- Packaging Dims = 116” x 51” x 78”