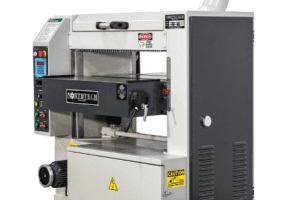

Cutter Heads:

- Cutterhead motor: 15HP, 3PH 230V or 460V

Product Dimensions:

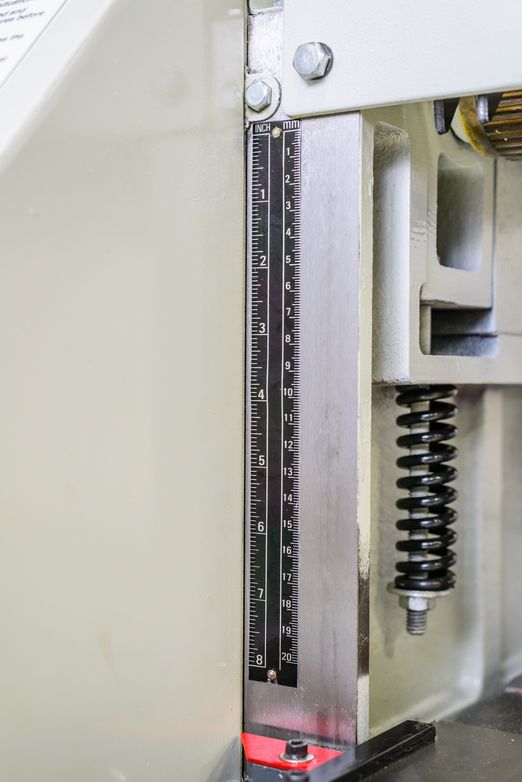

- Stocking thickness range: 3/16″ – 7.874″

- Max depth of cut: 5mm (3/16″)

- Max. width of stock: 610mm (24″)

- Cutterhead diameter: 80mm (3-1/4″)

Feed System:

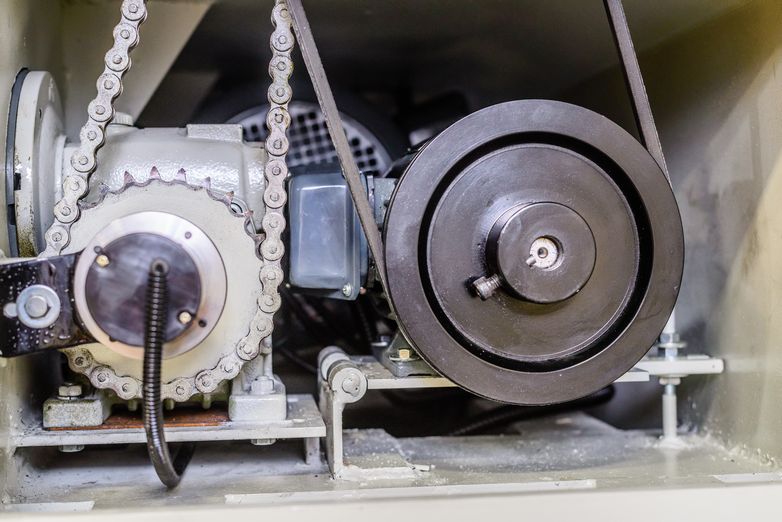

- Power table motor: 1HP

- Feed drive motor: 1HP

Features:

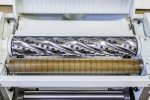

- 24″ Helical Head with (6) rows of 15 x 15 x 2.5mm 4-way carbide inserts.

- The spiral cutter head provides a high chip removal rate and superior surface finish at low noise levels.

- Range of feed speed: 0-75 ft./min. variable inverter.

- Quick-adjust bed rollers

- Powered table elevation for fast and convenient thickness setting via digital control.

- Extra-heavy rib-reinforced cast iron table with a precision ground surface.

- Corrugated sectional infeed roller has independent sections for running strip stock of varying thicknesses.

- Table area: 25″ x 27-1/4″ (635 x 692mm)

- Net weight 1,525 lbs. Gross weight 1,630 lbs.

- Packing dimensions: (L) 49″ x (W) 36″ x (H) 54″

- (1) Toolbox

- The warranty is one-year parts

- All machines are tested stateside prior to shipment providing trouble-free start-up.

Specifications:

- Top Head Hp. = 15 Hp.

- Voltage/ Freq. = 230/460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 39/19.5 Amps

- Feed Hp. = 1 Hp.

- Feed System = Segmented Roller / Power Rolle

- Drive System = Belt

- Feed Speed = 5 – 70 FPM

- Variable Speed = Inverter Controlled

- Elevation Hp. = 1 Hp.

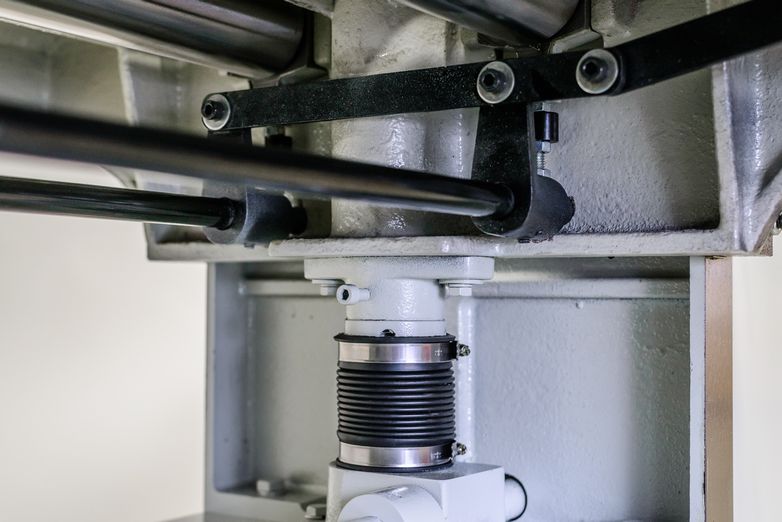

- Elevation Style = REC 727M Elevation Control

- Elevation Sys. = (2) Post Jack Screw

- Total Hp. = 17 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 110 Volt

- Programmable = REC 727M Elevation Control

- Min. Length = 10”

- Max. Width = 24”

- Min. Thickness = 3/16″

- Max. Thickness = 7-3/4”

- Cutter Head RPM = 5250 Rpm

- Tooling = 15 x 15 x 2.5 mm

- Head Type = Dynamically Balanced Helical Head

- Cutter Head Dim = 3-3/4” x 24”

- Cut Head Matl. = Alloy Steel

- Rows of Cutters = 6 Rows

- No. of Inserts = 144 Inserts

- Insert Size = 15 x 15 x 2.5 mm

- Dust Collection = 981 CFM @ Extraction Point

- Dust Port Out = 6” Top

- Digital Display = Elevation and Feed Speed

- Powered Rollers = 2 Top Powered Rollers

- Idle Rollers = (2) Idle Bed Rollers

- Pressure Shoes = 24” Spring Loaded Pressure

- Frame Const. = 1/4” Steel/Cast Iron Construc

- Infeed Table = 15-1/2” 3 Roll Infeed Table

- Decible Rating = 77 dB

- Net Weight = 1525 Lbs.

- Gross Weight = 1630 Lbs.

- Machine Dims. = 43” x 45” x 55”

- Packaging Dims = 36” x 49” x 54”