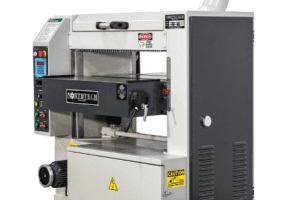

Cutter Heads:

- Cutterhead Motor: 10HP, 3PH 230V

Features:

- Solid cast iron construction

- 20 Segmented infeed rollers and chip breakers

- 10HP cutter head drive

- Heavy-duty jack lifting screws

- Solid steel outfeed roller

- High polished cast iron feed bed with ball bearing bed rollers

- All gear feed system

- All surfaces are precision ground providing years of smooth and accurate surfacing

- Dust hood is included (4″ outlet)

- DC/VS Variable feed speed 0 – 70′ min

- Manual table elevation for fast and convenient thickness setting, with M-10 LED Electronic Readout for Table Height

- 3″ diameter cutter head with 3 ¼” cutting circle; 6,850RPM

- 15x15x2.5 straight insert knives; 6 rows (120 total knives)

- Stock thickness: 3/16″ – 8″

- Maximum depth of cut: ¼” Table size is 21″ x 27 ¼”

- Gross weight: 1,140 lbs.

- One year parts warranty

- Includes operator’s manual and parts book.

- All machines are tested stateside prior to shipment providing trouble-free start-up.

Specifications:

- Top Head Hp. = 10 Hp.

- Voltage/ Freq. = 230 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 25 Amps

- Feed Hp. = 1 Hp.

- Feed System = Segmented Roller / Power Rolle

- Drive System = Belt

- Feed Speed = 0 – 70 FPM

- Variable Speed = Inverter Controlled

- Elevation Hp. = 1 Hp.

- Elevation Style = Manual Wheel Adjustment

- Elevation Sys. = (2) Post Jack Screw

- Total Hp. = 11 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 230 Volt

- Operator Panel = Adjustable Operator Panel

- Min. Length = 9”

- Min. Width = 1″

- Max. Width = 20”

- Min. Thickness = 3/16″

- Max. Thickness = 8”

- Cutter Head RPM = 6850 RPM

- Tooling = 15 x 15 x 2.5 mm

- Head Type = Dynamically Balanced Helical Head

- Cutter Head Dim = 3” x 20”

- Cut Head Matl. = Alloy Steel

- Rows of Cutters = 6 Rows

- No. of Inserts = 120 Inserts

- Insert Size = 15 x 15 x 2.5 mm

- Dust Collection = 436 CFM @ Extraction Point

- Dust Port Out = 4” Top

- Powered Rollers = 2 Top Powered Rollers

- Idle Rollers = (2) Idle Bed Rollers

- Pressure Shoes = 20” Spring Loaded Pressure

- Frame Const. = 1/4” Steel Construction

- Decible Rating = 77 dB

- Net Weight = 1060 Lbs.

- Gross Weight = 1140 Lbs.

- Machine Dims. = 33” x 41” x 57-1/2”

- Packaging Dims = 32” x 48” x 45”