Features:

- Close link chain vs. traditional open (pinch point)

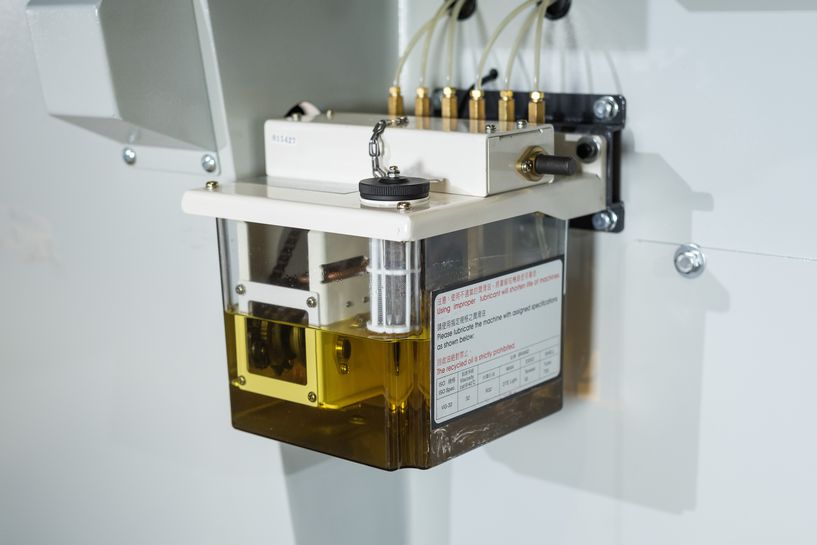

- Auto lube system oiler has twice the number of lube points (critical)

- Can cut up to 3-15/16″ with MRS-12 12″ blade.

- Bottom kickback fingers for added safety

- Glue line rip capable

- Speed of saw blade 3550 RPM

- Variable feed speed 30’ – 125’ per minute

- Include (1) carbide blades: 12″ x 36T x 70mm x 3.5mm kerf

- Net Weight: 3,300 lbs.

- Packing Weight: 3,525 lbs.

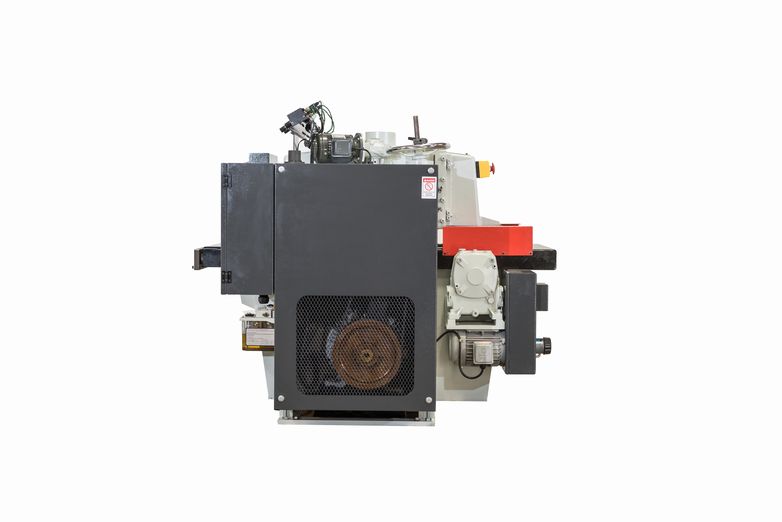

- Dimensions: 72”L x 62”W x 64”H

- (1) Toolbox

- Warranty is one-year parts

- All machines are tested stateside prior to shipment providing trouble-free start-up.

Outstanding Features:

- Exclusively designed lubricator provides excellent performance.

- Close link feed chain for added operator safety protection.

- Short stock hold-down shoes allow for the cutting of small or thick materials.

- (2) rows anti-kickback fingers at infeed.

- Power raise & lower of the top pressure group is an optional feature.

- The machine is ruggedly constructed throughout for maximum stability.

- A precision saw arbor gives an accurate and smooth cut.

Specifications:

- Main Motor Hp. = 40 hp.

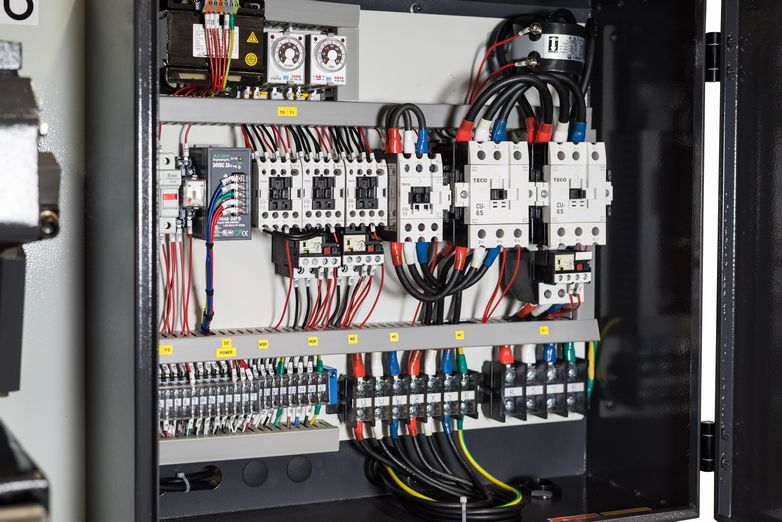

- Voltage/ Freq. = 230460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 100/50 Amps

- Feed Hp. = 2 Hp.

- Feed System = 12” Dip Chain

- Drive System = Variable Speed Pulley

- Feed Speed = 30 – 125 FPM

- Variable Speed = Mechanical Wheel Adjustment

- Elevation Hp. = 1/4 Hp.

- Elevation Style = Push Button

- Elevation Sys. = Jack Screw / Linear Guides

- Total Hp. = 50 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 110 Volt

- Assisted Start = Wye-Delta

- Pass-Line = 29-1/2”

- Min. Length = 7” Butt Feed 12” Single

- Min. Width = 1/2”

- Max. Width = 12”

- Min. Thickness = 1/4”

- Max. Thickness = 3-15/16”

- Arbor Rpm = 3550 Rpm

- Blade Size = 12” Tungsten Carbide Tipped

- No. of Teeth = 36 Tooth

- Tooth Spacing = 1-3/16”

- Blade Kerf = 3.5 mm

- Cleaning System = Brush on Chain

- Vertical Travel = 1/4” – 4-3/16”

- Dust Collection = (2) 6” @ 1962 CFM

- Arbor Diameter = 70 mm

- Hold Down Style = (6) Rollers Throat Plate

- Kickback Finger = (48) Top (30) Bottom

- Emergency Stop = Push Button

- Rear E Stop = Push Button

- Safety Feature = Safety Interlock Switch

- Guarding = High Visibility Guarding

- Oiler = Auto Oiler

- Low Oil Warning = Low Oil Shut-off

- Frame Const. = 1/4” Steel Construction

- Worktable Dims. = 21-1/2” x 67”

- Infeed Table = 99-1/2”

- Laser = 100mw Laser Light & Mount Bracket

- Decible Rating = 76 dB

- Net Weight = 3266 Lbs.

- Gross Weight = 3466 Lbs.

- Machine Dims. = 67” x 57” x 57”

- Packaging Dims = 72” x 40” x 31”