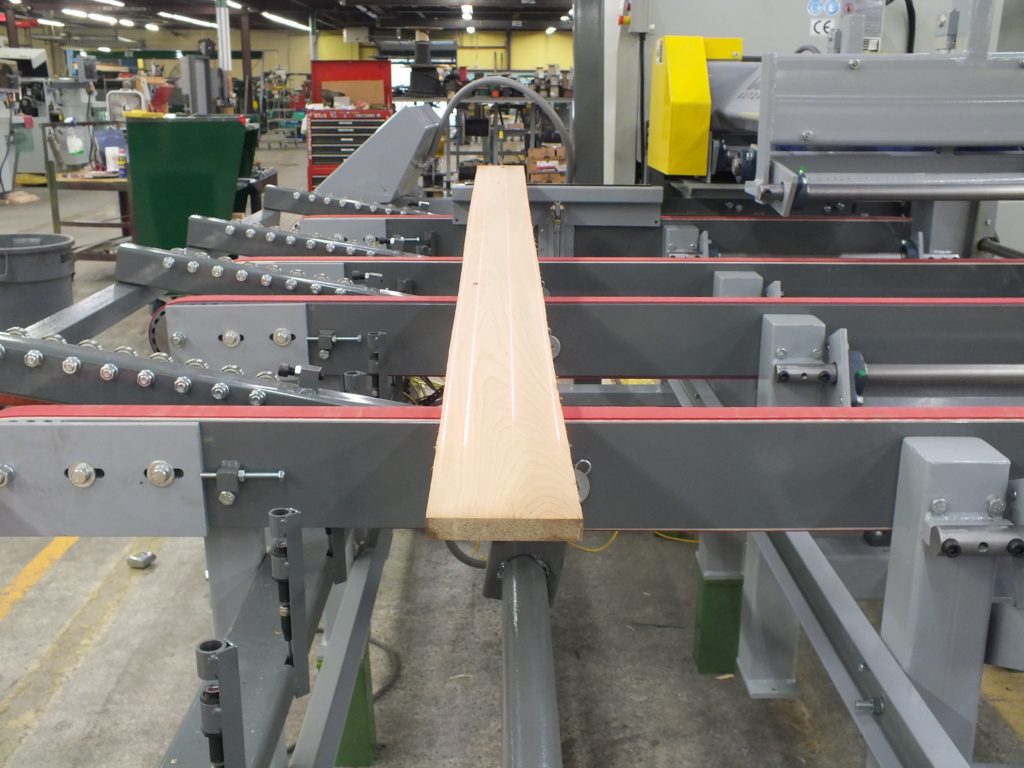

The Quick Rip system works as follows: An operator places the boards, one at a time, on a servo-controlled series of the belts. The belts then accelerate the board to be processed past multiple sensors that measure the board every foot for the length and width, to determine its full profile. Next, the belts accurately position the board under a series of laser lights, presenting the operator with the optimum rip combination based on the measured width.

The operator can then choose an alternate rip pattern, fine tune the positioning and/or skew the board to the angle that will result in the optimum rip. With the optional Auto Skew feature, this can be done automatically while the operator is loading the next board. When the operator is happy with the positioning of the board, a button is pressed and the belts then position the board in front of the rip saw where a series of pinch rollers lift the board and feed it into the saw. A major advantage to this novel method is that lumber can be skewed on the conveyor, resulting in an increase in yield.

Existing gang rip saw optimization systems incorporate a straight fence, usually working in conjunction with cant rollers, to position the lumber before it enters the saw. Unfortunately, this orientation is not always the proper orientation to achieve maximum yield. The Quick Rip solves this problem by using a precision servo-controlled belt system to position the lumber from the belt and feeds it into the saw, maintaining its orientation.

Typical Quick Rip users:

- Moulding & Millwork Shops

- Mid-Size Cabinet Manufacturers

- Window & Door Manufacturers

- Wholesale Lumber Distributor

Production:

- Current Installation Production Rates

- Minimum = 3000 – 4000 bd. ft. per Day

- Maximum = 16,000 – 20,000+ bd. ft. per Day

- Max Production

- Typically Includes a Material Handling Outfeed System

- (1) Operator Loading the Infeed

- Outfeed Chains to Catch Rips and Cross Transfer

- (1 – 2 ) Operators pulling Material from the Chains into Carts

- (10 – 12+) 10 Ft. Long Boards per Minute

- (2) Operators

- (1) Operator loading the Infeed and (1) Operator Tailing the Machine

- (5 – 6) 10 Ft. Long Boards per Minute

- (3) Operators

- (1) Operator Loading the Infeed and (2) Operators Tailing the Machine

- (8 – 10) 10 ft. Long Boards per Minute

Cameron Quick Rip Infeed

- Lumber Capacities

- Standard Machine: 5 Ft. Minimum / 16 Ft. Maximum

- Short Stock Machine: 42″ Minimum / 16 Ft. Maximum

- Thickness Tolerances

- 12″ Saw Blades: 2.5″

- 14″ Saw Blades: 4″

- Maximum Width (Incoming Material)

- 20″ Wide

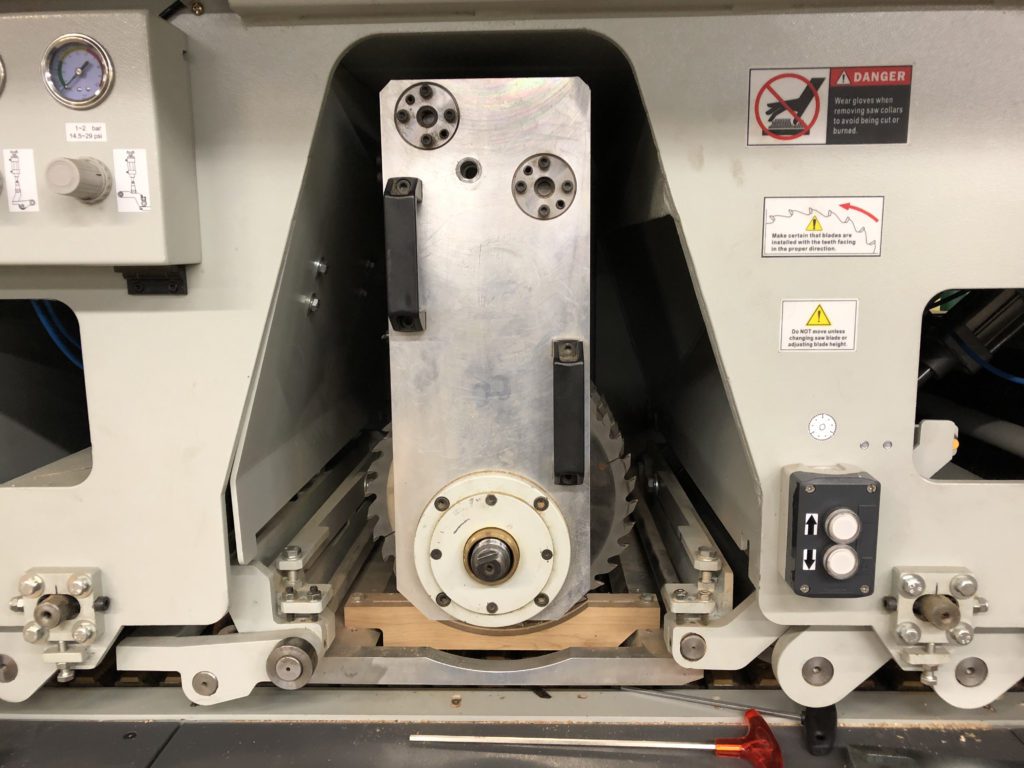

Cameron #413B- Rip Saw (Most Common Package)

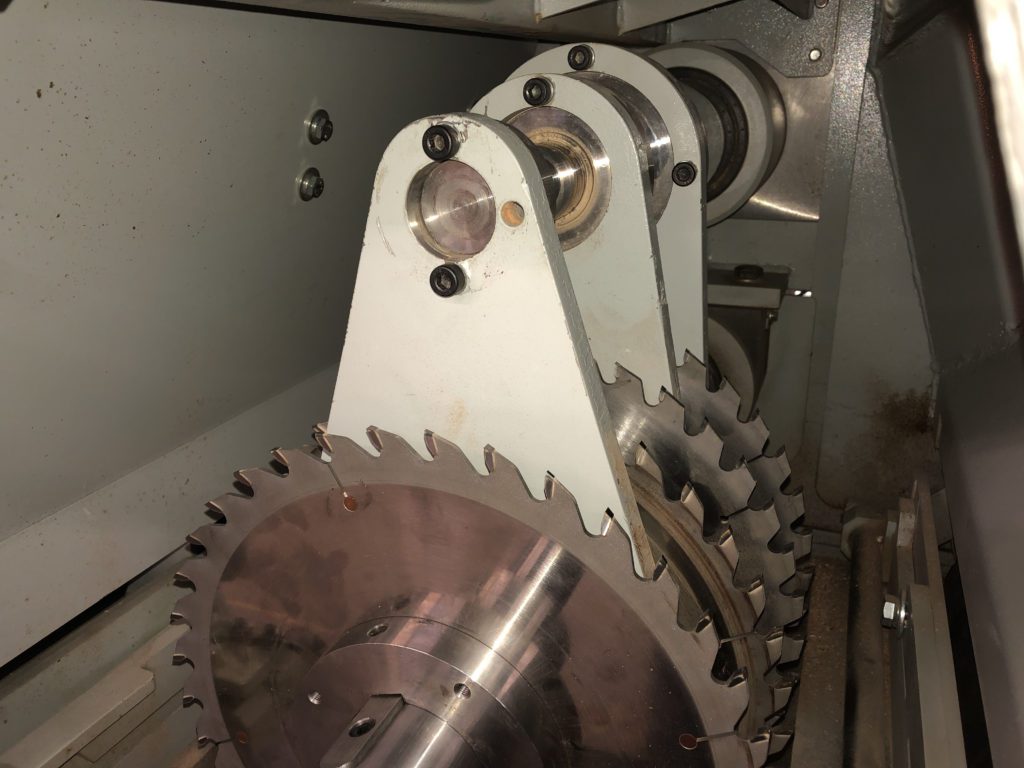

- (3) Servo Controlled Movable Blades

- Multiple Fixed Blades

- Pocket Sizes between Saw Blades

- Between (2) Fixed Blades: 1″

- Between Fixed Blade and 1st Movable Blade: 1″

- Between (2) Movable Blades: 1.875″

- Feed Speed

- Minimum: 26 ft/min (8 m/min)

- Maximum: 180 ft/min (55 m/min)

- Electric Motors:

- Arbor Motor: 60 Hp

- Feed Motor: 5 Hp

- Three (3) sets of anti-kickback fingers

- (4) individual Pneumatic pressure rolls

- Steel Double V dip chain construction with urethane inserts

- Powered out-feed roller

- Automatic lubricator for feed chain.

- Amp meter for monitoring arbor motor running amperage

- Easily accessed v-belt driving saw arbor for reduced vibration and higher tolerances

- Easy access to spindle and blades for maintenance and tooling changes

Cameron Rip Software:

- Yield Improvement over Hand feeding

- Increased Safety for Operator

- Full Production Tracking that includes:

- Production Tallies

- Rough Lumber tracking by length and Yield

- Arbor Optimization (mainly used with large fixed arbor saws)

- Bundle reports on packs of lumber

- Simulation capabilities to simulate jobs before the wood ever hits the infeed

- Product Value Decisions: software can choose rip widths based on which rips are more profitable for your company.

Benefits of a Cameron Rip System:

- Award winning support.

- Software for both the Infeed and Gang Saw is written in house in Poughkeepsie, NY

- Industry leading features with the Auto-Skew and Over/Under design.

- Powerful Software to help improve your business and make you more profitable.

- Significant Yield Increases that go directly to the Bottom Line by decreasing Lumber Bills and Improving Productivity