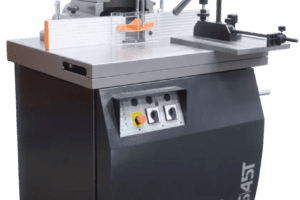

Features:

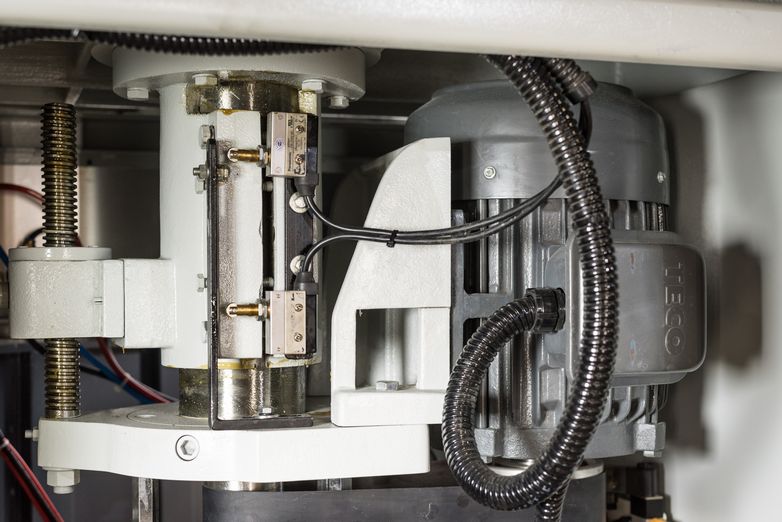

- 3,000 – 13,350 RPM, 10HP inverter controlled spindle

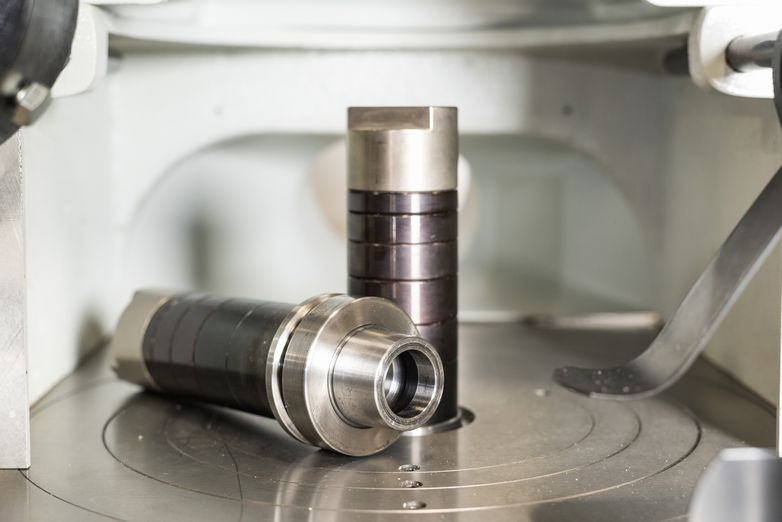

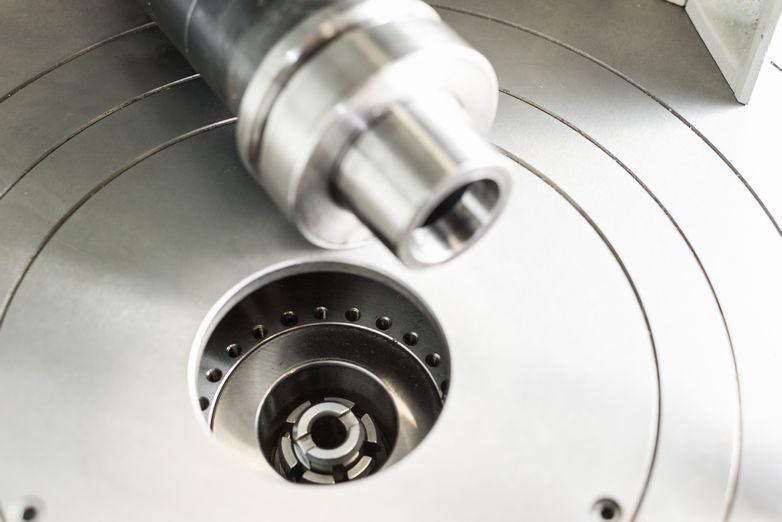

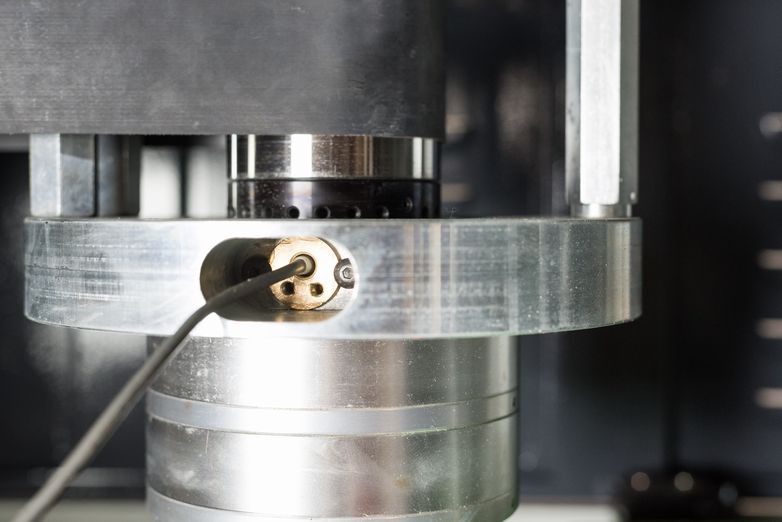

- (1) 1-1/4” HSK-63F spindle included

- HSK-63F spindle release system is developed by Andi CNC Machining Centers

- Spindle tolerance of .0001″ *

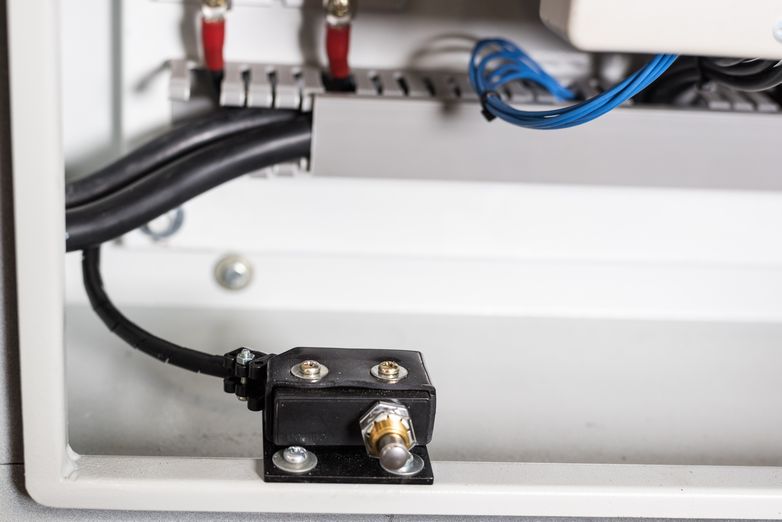

- Includes sensor light to ensure proper mating of the chucks as well as correct full pneumatic pressure for safety

- Moveable overarm control panel

- 35″ Ergonomically designed precision-milled table

- Optional sliding table has 58” of sliding ability 29” Left 29” Right

- (1) Toolbox

- Warranty is one-year parts

- All machines are tested stateside prior to shipment providing trouble-free start-up.

Specifications:

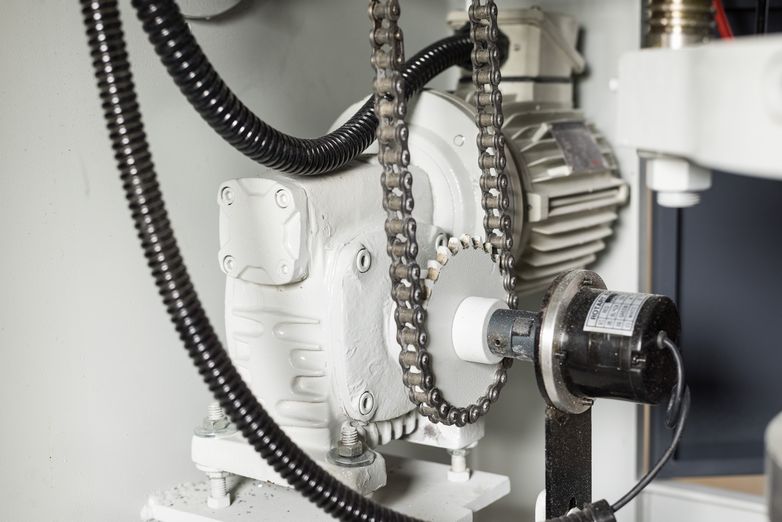

- Main Motor Hp. = 10 hp.

- Reverse Motor = Reversible

- Voltage/ Freq. = 230 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 30 Amps

- 1st Spindle = 1-1/4” x 4” Spindle

- Spindle Diam. = 1-1/4”

- Spindle RPM = 13350 Rpm Adjustable

- Under Nut Cap. = 4”

- Elevation Hp. = 1 Hp.

- Elevation Style = Push Button

- Elevation Sys. = Jack Screw / Quill Housing

- Total Hp. = 11 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 110 Volt

- Programmable = Elevation

- Operator Panel = Adjustable Operator Panel

- Pass-Line = 35”

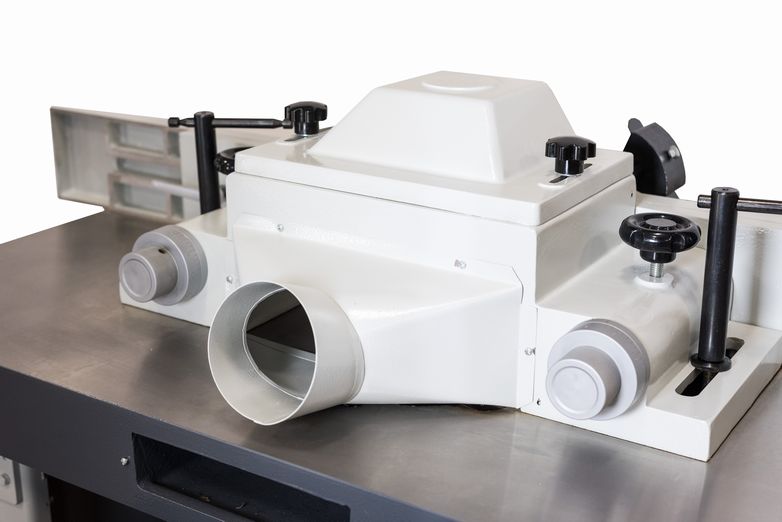

- Dust Collection = (1) 4” (1) 5” @ 1117 CFM

- Dust Port Out = (1) 4” (1) 5”

- Digital Display = Elevation

- FLR Included = Filter, Lubricator, Regulator

- Recommended CFM = 1/4” Line @ 90 PSI

- Emergency Stop = Push Button

- Fence Type = Adjustable

- Fence Dims. = (2) 5-1/2” x 24”

- Micro Fence = Micro-Adjustable

- Brake System = Electronic Braking

- Frame Const. = 1/4” Steel Construction

- Worktable Dims. = 61” x 38” x 35”

- Table Const. = Cast Iron

- Measure Meth. = Precision Encoder

- Decible Rating = 80 dB

- Net Weight = 1690 Lbs.

- Gross Weight = 1890 Lbs.

- Machine Dims. = 62” x 43” x 67”

- Packaging Dims = 68” x 47” x 75”