Cameron Rip Systems:

The Skew is a highly efficient, inexpensive, full featured, rip optimization system designed to fit any 12″ wide gang rip saw and specifically developed for the custom shop. The unique feature of The Skew is the “skewing fence”. It has the ability to twist and feed the board into the saw to get the best yield. The Skew also has all the features of the high-end optimization systems like: lumber tallying, pack reporting, bundle reporting, yield calculations, simulations, and much more. The greatest benefit of The Skew is the Return on Investment, which can be well under 1 year. Many Skew Systems include a Cameron (2) or (3) Moving Blade Rip Saw

The Quick Rip is fenceless and has Auto Skewing for achieving highest possible yield. Our sensors read the width, the length, and the shape of the boards. If a board has crook or taper, our software can determine if the board should be skewed for higher yield. If so, it happens automatically. This adds up to an additional 3% yield over systems with a fence. Quick Rips can be paired with Moving Blade Saws that come with (2), (3) or (4) Moving Blades Depending on your Cut Bill and Lumber. The Cameron Opti-Rip software is written in-house allowing changes, improvements and free upgrades to happen on a regular basis.

The Automated Opti-Rip optimization system is very adaptable to many material handling systems. As Cameron Automation’s Largest Infeed for the High Production Lumber Mills and Large Woodworking Factories. Some of our systems are fed manually from a scissor lift of planed lumber, some systems have a landing deck and are fed from the outfeed conveyor of a planer and some systems are fed by destackers and singulation machines. The Automated Opti-Rip automates the whole line, allowing one operator to run the system from destacker to Rip Saw.

The Rip-One Scanning Infeed is a complete lumber scanning, optimization, and gang ripping work cell designed for smaller shops. The Rip-One uses high resolution scanning technology to view both sides of a board to capture board dimensions and defects. The high resolution images are used to optimize each and every board going through the system. It also increases productivity dramatically by transforming gang ripping into a single person operation.

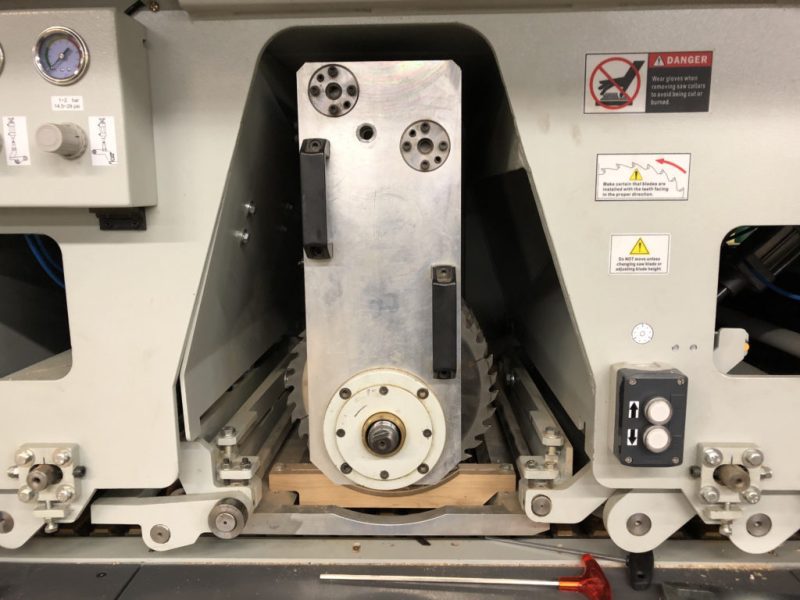

Cameron #413A- Rip Saw

- 12″ Wide Solid Arbor

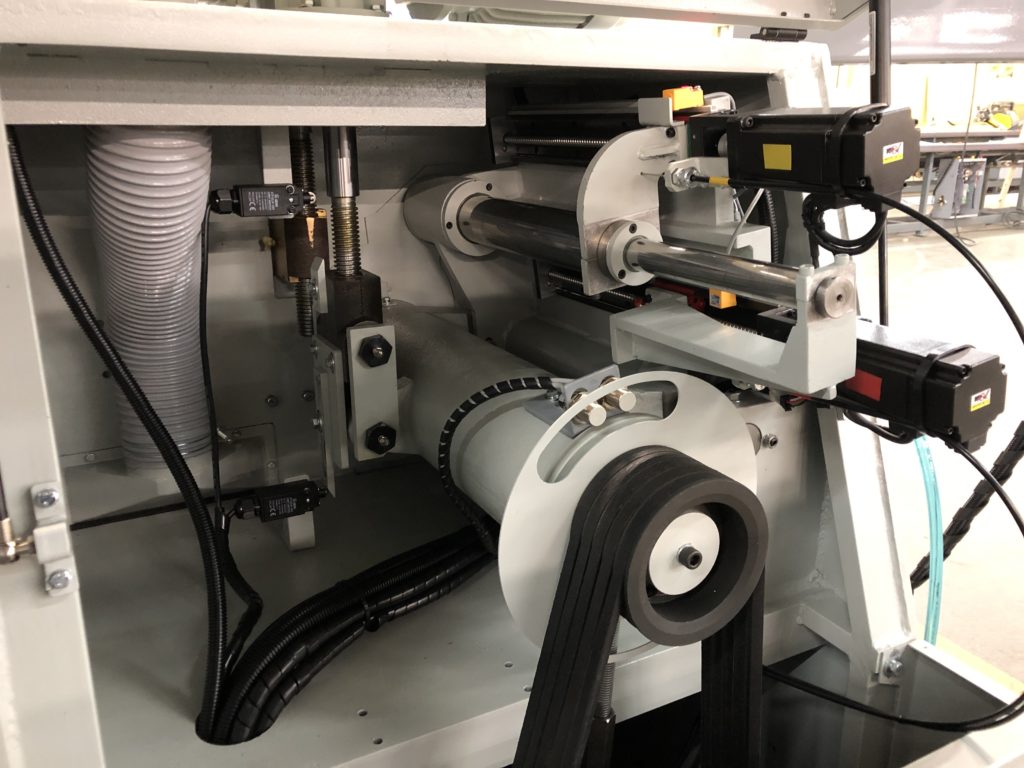

- (2) Servo Controlled Movable Blades

- Multiple Fixed Blades

- Pocket Sizes between Saw Blades

- Between (2) Fixed Blades: 1″

- Between Fixed Blade and 1st Movable Blade: 1″

- Between (2) Movable Blades: 1.875″

- Feed Speed

- Minimum: 26 ft/min (8 m/min)

- Maximum: 130 ft/min (40 m/min)

- Electric Motors:

- Arbor Motor: 50 Hp

- Feed Motor: 3 Hp

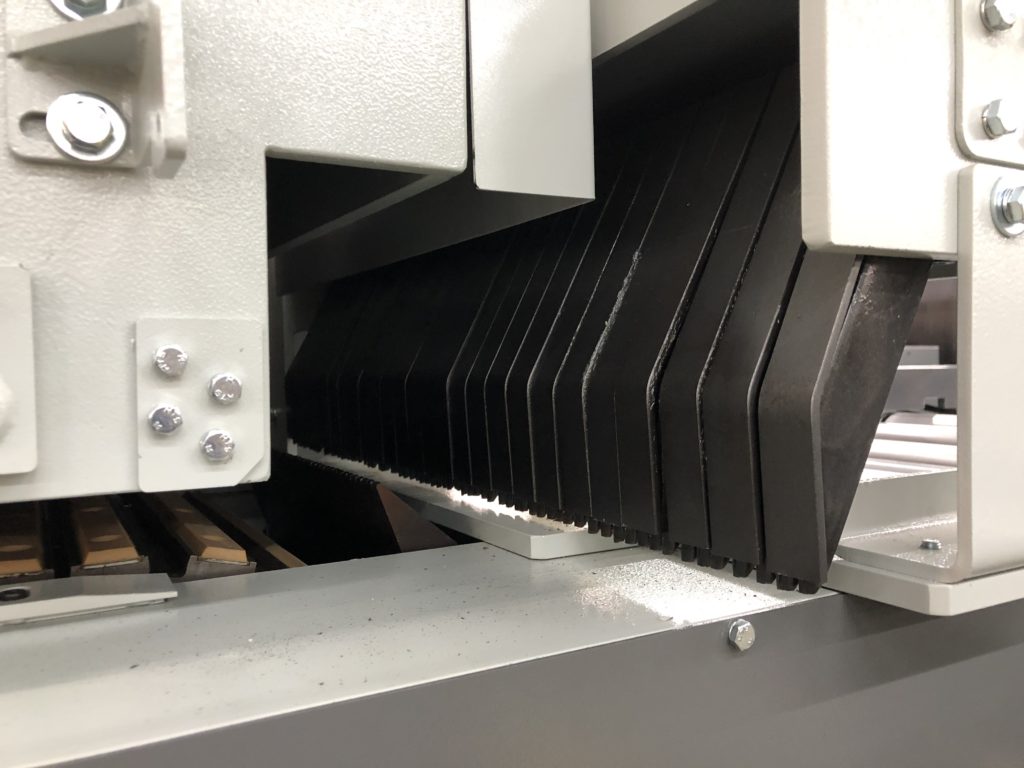

- Three (3) sets of anti-kickback fingers

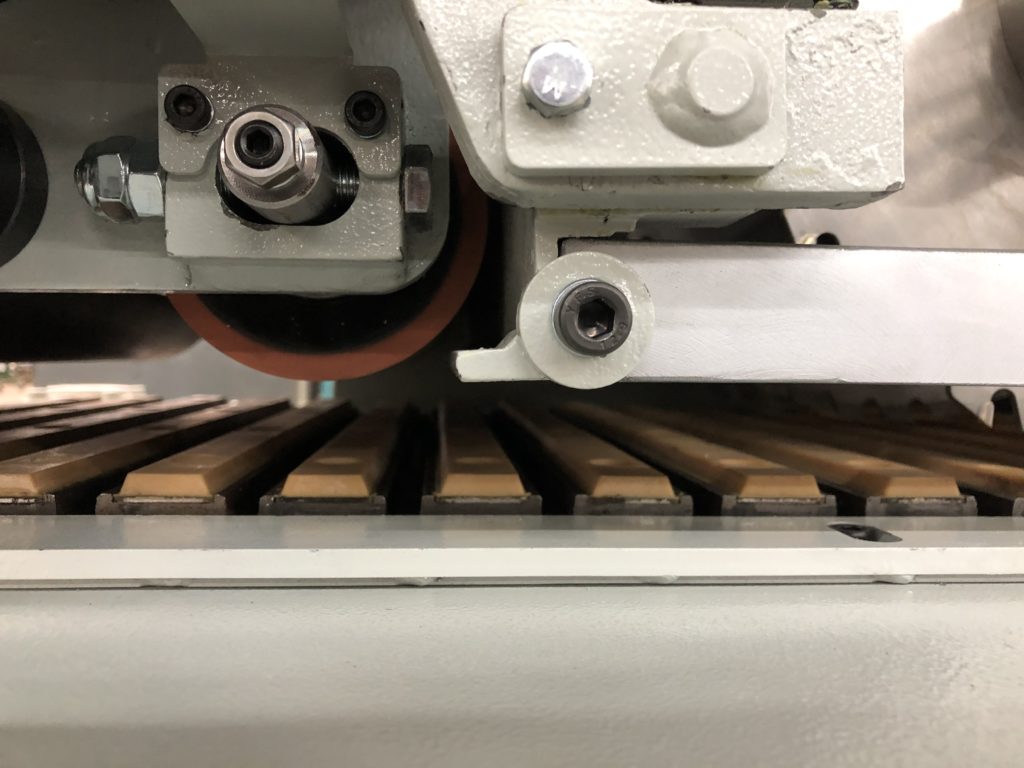

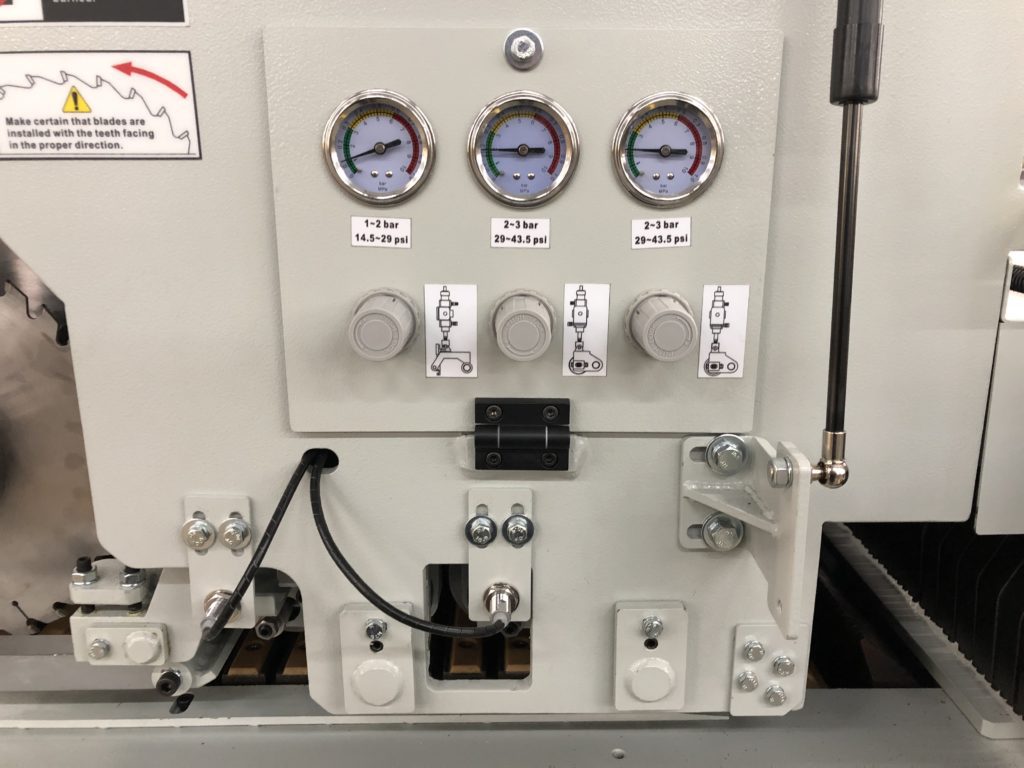

- (4) individual Pneumatic pressure rolls

- Steel dip chain construction with urethane inserts

- Powered out-feed roller

- Digital controlled lubricator for feed chain.

- Amp meter for monitoring arbor motor running amperage

- Easily accessed v-belt driving saw arbor for reduced vibration and higher tolerances

- Easy access to spindle and blades for maintenance and tooling changes

Cameron #413B- Rip Saw

- 18″ Wide Solid Arbor

- (3) Servo Controlled Movable Blades

- Multiple Fixed Blades

- Pocket Sizes between Saw Blades

- Between (2) Fixed Blades: 1″

- Between Fixed Blade and 1st Movable Blade: 1″

- Between (2) Movable Blades: 1.875″

- Feed Speed

- Minimum: 26 ft/min (8 m/min)

- Maximum: 180 ft/min (55 m/min)

- Electric Motors:

- Arbor Motor: 60 Hp

- Feed Motor: 5 Hp

- Three (3) sets of anti-kickback fingers

- (4) individual Pneumatic pressure rolls

- Steel Double V dip chain construction with urethane inserts

- Powered out-feed roller

- Automatic lubricator for feed chain.

- Amp meter for monitoring arbor motor running amperage

- Easily accessed v-belt driving saw arbor for reduced vibration and higher tolerances

- Easy access to spindle and blades for maintenance and tooling changes

Cameron #413C- Rip Saw

- 24″ Wide Solid Arbor

- (4) Servo Controlled Movable Blades

- Multiple Fixed Blades

- Pocket Sizes between Saw Blades

- Between (2) Fixed Blades: 1″

- Between Fixed Blade and 1st Movable Blade: 1″

- Between (2) Movable Blades: 1.875″

- Feed Speed

- Minimum: 26 ft/min (8 m/min)

- Maximum: 200 ft/min (60 m/min)

- Electric Motors:

- Arbor Motor: 60 – 75 Hp

- Feed Motor: 5 Hp

- Three (3) sets of anti-kickback fingers

- (4) individual Pneumatic pressure rolls

- Steel Double V dip chain construction with urethane inserts

- Powered out-feed roller

- Automatic lubricator for feed chain.

- Amp meter for monitoring arbor motor running amperage

- Easily accessed v-belt driving saw arbor for reduced vibration and higher tolerances

- Easy access to spindle and blades for maintenance and tooling changes

Cameron Rip Software:

- Yield Improvement over Hand feeding

- Increased Safety for Operator

- Full Production Tracking that includes:

- Production Tallies

- Rough Lumber tracking by length and Yield

- Arbor Optimization (mainly used with large fixed arbor saws)

- Bundle reports on packs of lumber

- Simulation capabilities to simulate jobs before the wood ever hits the infeed

- Product Value Decisions: software can choose rip widths based on which rips are more profitable for your company.

Benefits of a Cameron Rip System:

- Award winning support.

- Software for both the Infeed and Gang Saw is written in house in Poughkeepsie, NY

- Industry leading features with the Auto-Skew and Over/Under design.

- Powerful Software to help improve your business and make you more profitable.

- Significant Yield Increases that go directly to the Bottom Line by decreasing Lumber Bills and Improving Productivity