| Features: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2009 IMA HKA Contour Edegbander

2009 IMA HKA Contour Edegbander

JLT 8 Section Pneumatic DOOR PRO 79X-8-A Rotary Door Clamp

JLT 8 Section Pneumatic DOOR PRO 79X-8-A Rotary Door Clamp

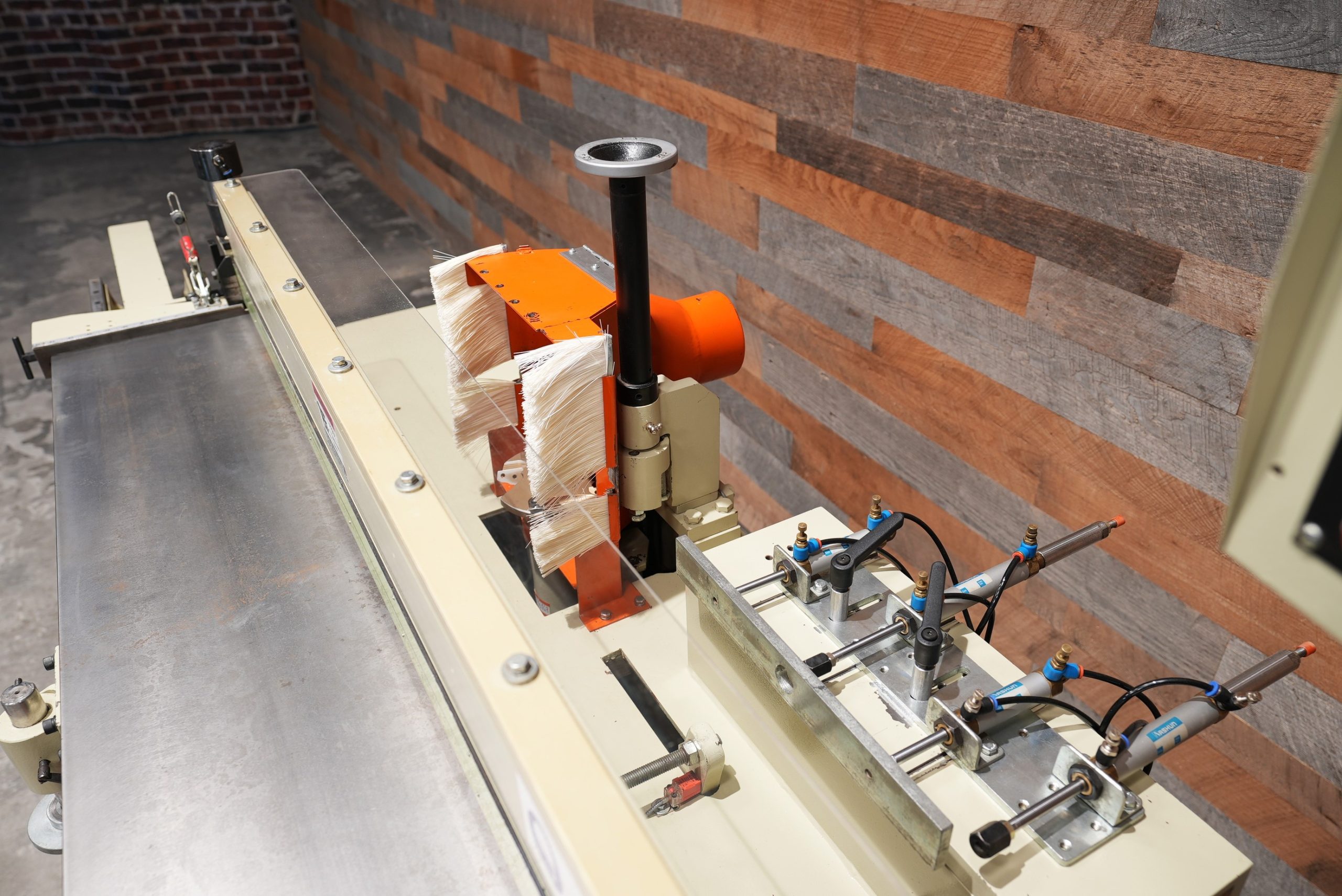

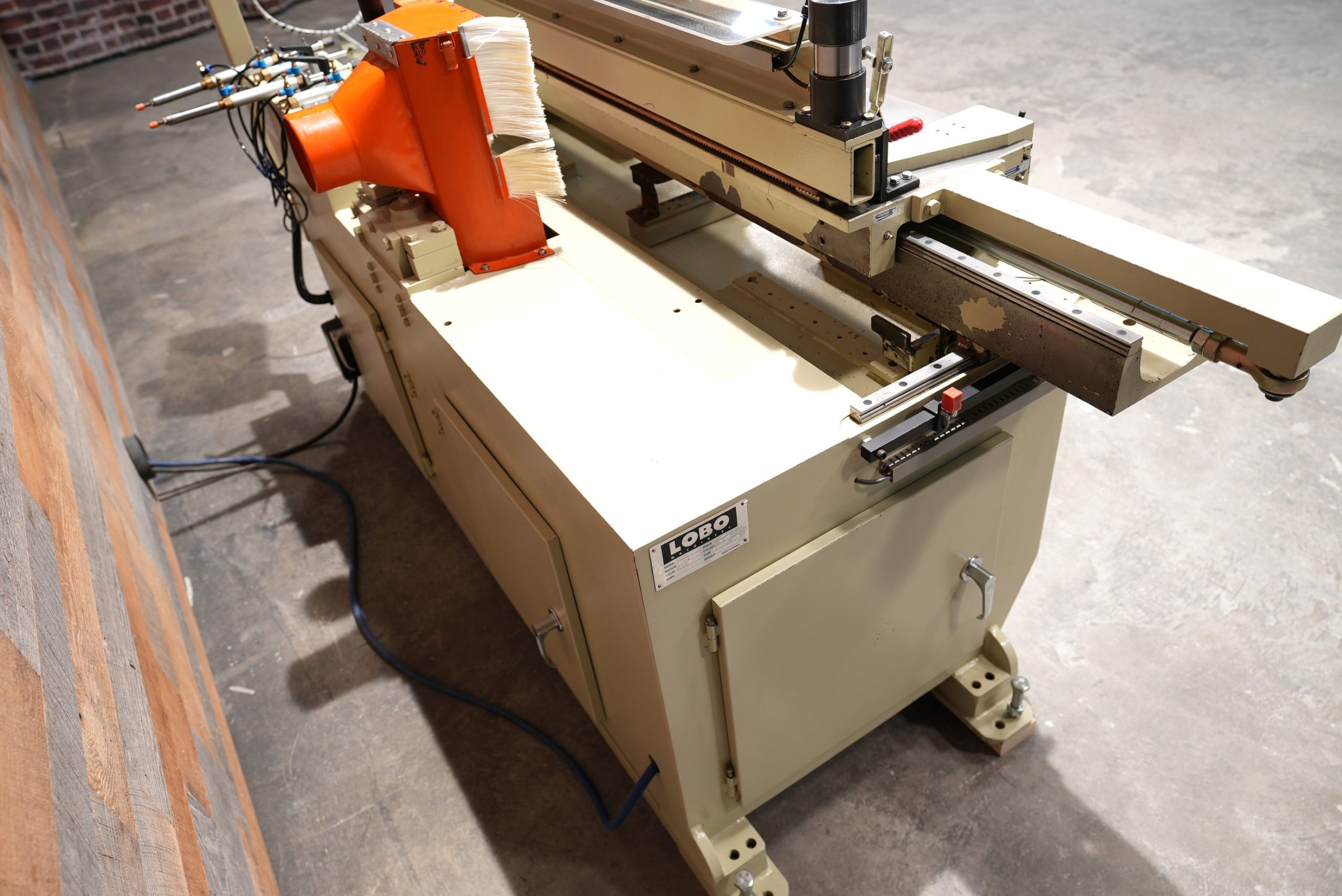

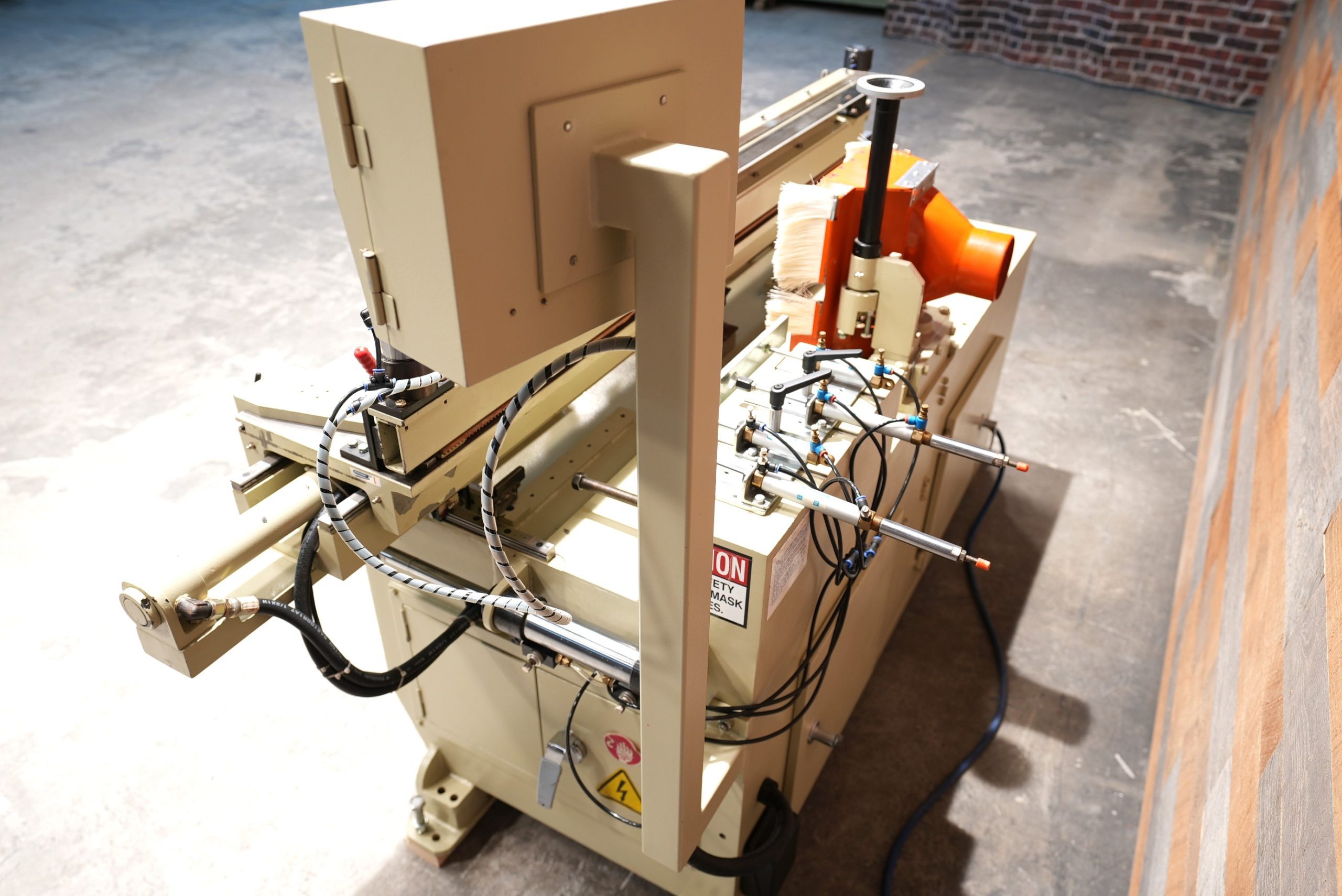

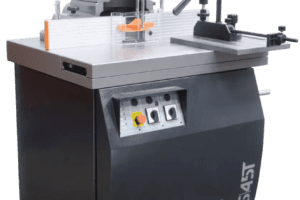

Lobo 1400 Automatic Raised Panel Door Machine

Original price was: $13,500.00.$11,500.00Current price is: $11,500.00.

-15%This is a very clean, Lobo 1400 Automatic Raised Panel Door Machine. The “Automatic” means that it is hydraulically fed. The 6″ high stackable 1-1/4″ spindle has 3 pneumatic stops (panel/rail/cope). The main spindle is powered by a 10 HP motor while the feed is powered by a 1 HP hydraulic motor. The sliding carriage allows for panels up to 55″ in length.

This fully functional machine has been fully cleaned, checked, and is ready to work from the time you receive it. This is our guarantee to both you and your company. It is owned by 360 Degree Machinery and located in our inventory in Kingston, TN.