Cameron Automation has pushed the envelope once again to simplify sophisticated equipment and bring it to the small shop to increase yield and save labor.

How it Works:

- A Board is placed on the Infeed Section

- The system measures the width, length, and shape of the board using sensors placed at 1’ increments

- With our unique “Skewing Fence”, the machine adjusts the angle and position of each board to achieve the highest possible yield

- The laser lights move with the saw blades to project the rip solution on the board

- The operator has several options available to improve the final rip solution. Once that is determined, the board is processed into the saw and the next board is measured

- The Cameron Software Actively Tallies all Production, constantly updating a number of reports that can be saved.

This System Features:

- Full Optimizing Infeed

- 12″ Wide Arbor, (2) Moving and Multiple Fixed Blade Rip Saw

- Auto-Skew to Increase Board Yield

- Fully Integrated Software Package

- Automatic Movable Blade Positioning by the Cameron Software

The Skew is our answer for Rip Optimization in a custom shop. It will quickly transform a labor intensive hand fed rip work cell, into an efficient and effective. Cameron has further refined their rip software to make it easy and affordable for the small shop.

Production:

- (1) Operator

- (2 – 3) 10 Ft. Long Boards per Minute

- (2) Operators

- (4 – 5) 10 Ft. Long Boards per Minute

- Current Installation Production Rates

-

-

-

- Minimum = 900 – 1000 bd. ft.

- Maximum = 6,000 – 7,000 Bd. Ft.g changes

Cameron Skew Infeed

Lumber Capacities

Standard Machine: 5 Ft. Minimum / 16 Ft. Maximum

Short Stock Machine: 28″ Minimum / 16 Ft. Maximum

Thickness Tolerances

12″ Saw Blades: 2.5″

14″ Saw Blades: 3.75″

Maximum Width (Incoming Material)

15″ Wide

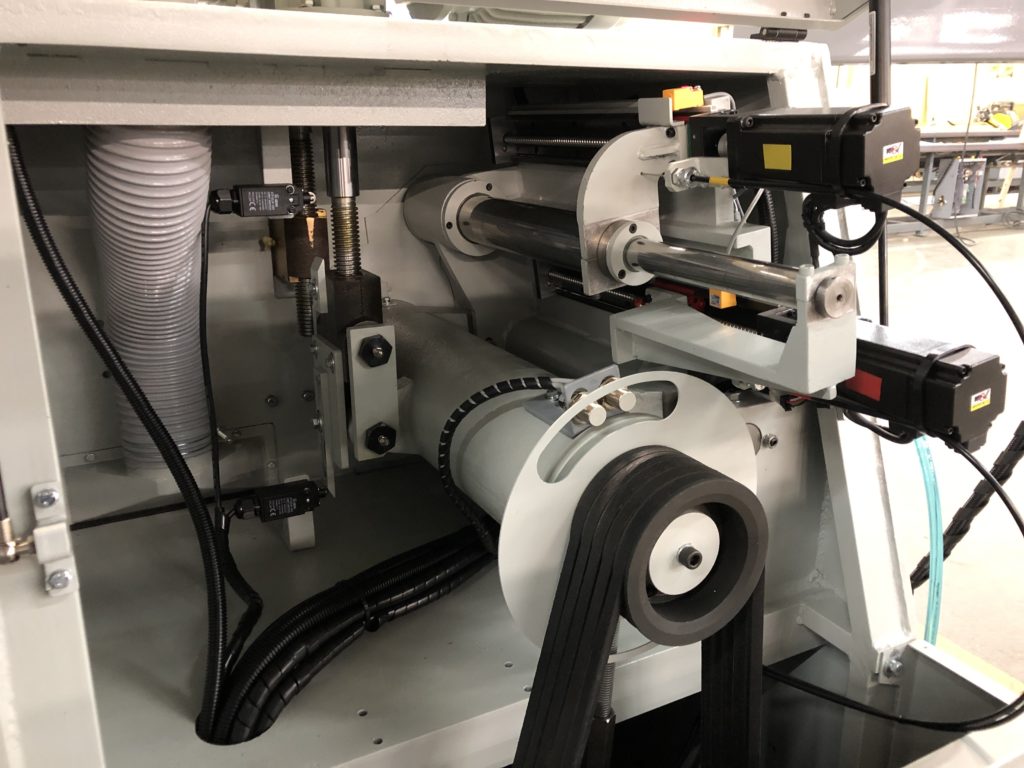

Cameron #413A- Rip Saw(2) Servo Controlled Movable Blades

Multiple Fixed Blades

Pocket Sizes between Saw Blades

Between (2) Fixed Blades: 1″

Between Fixed Blade and 1st Movable Blade: 1″

Between (2) Movable Blades: 1.875″

Feed Speed

Minimum: 26 ft/min (8 m/min)

Maximum: 130 ft/min (40 m/min)

Electric Motors:

Arbor Motor: 50 Hp

Feed Motor: 3 Hp

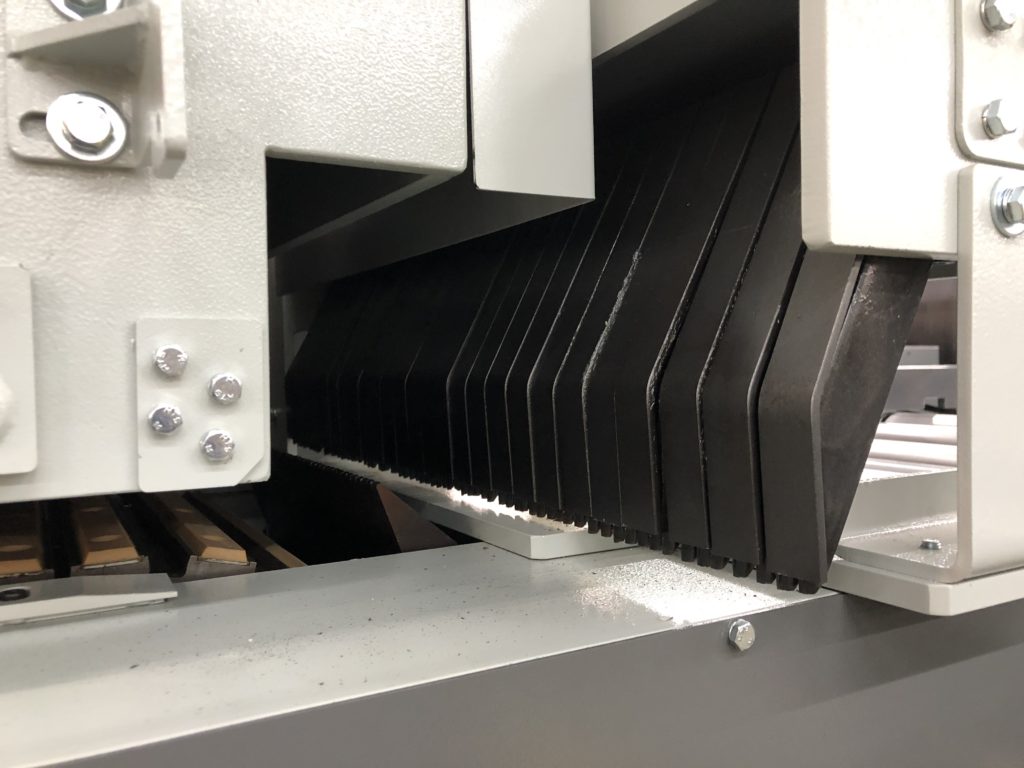

Three (3) sets of anti-kickback fingers

(4) individual Pneumatic pressure rolls

Steel dip chain construction with urethane inserts

Powered out-feed roller

Digital controlled lubricator for feed chain.

Amp meter for monitoring arbor motor running amperage

Easily accessed v-belt driving saw arbor for reduced vibration and higher tolerances

Easy access to spindle and blades for maintenance and tooling changes -

-

Cameron Rip Software:

Yield Improvement over Hand feeding

Increased Safety for Operator

Full Production Tracking that includes:

Production Tallies

Rough Lumber tracking by length and Yield

Arbor Optimization (mainly used with large fixed arbor saws)

Bundle reports on packs of lumber

Simulation capabilities to simulate jobs before the wood ever hits the infeed

Product Value Decisions: software can choose rip widths based on which rips are more profitable for your company.

Benefits of a Cameron Rip System:Award winning support.

Software for both the Infeed and Gang Saw is written in house in Poughkeepsie, NY

Industry leading features with the Auto-Skew and Over/Under design.

Powerful Software to help improve your business and make you more profitable.

Significant Yield Increases that go directly to the Bottom Line by decreasing Lumber Bills and Improving Productivity -