Features:

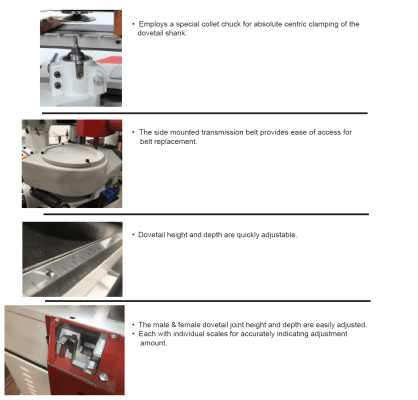

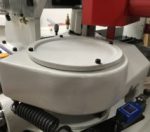

| Exclusively employs a special collet chuck for absolute clamping of the dovetail shank. This design fully guarantees vibration-free dovetail machining and operator safety while giving exacting fit capabilities. |

| The side-mounted transmission belt provides ease of access for belt replacement. |

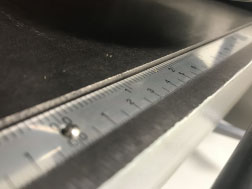

| Dovetail height and depth are fast and accurate of adjust. A machine-type metal rule permits accurate reading for ultra-fine adjustment of the dovetail joint and is set with a 1/2″ dovetail offset for quicker width sets. |

| Proprietary 6-speed feed to match all material types and thickness parameters |

| 2 speed motor with 3 step pulley is a standard feature ensuring perfect feed speed for all material types, including plywood. |

| The male & female dovetail joint height and depth are easily adjusted, equipped with individual scales for accurately indicating adjustment amount. |

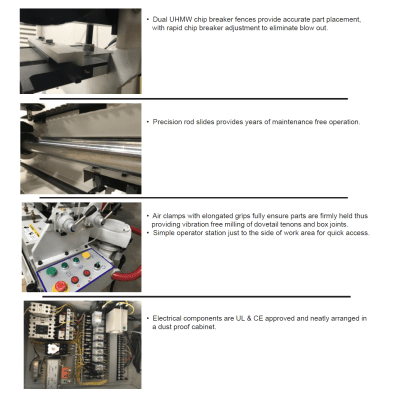

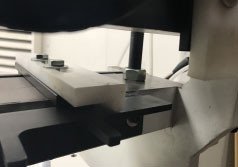

| Dual UHMW chip breaker fences provide accurate part placement, with rapid chip breaker adjustment to eliminate blowout. |

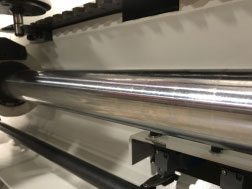

| Precision rod slide provides years of maintenance-free operation. |

| Dual air clamps with elongated grips fully ensure parts are firmly held thus providing vibration-free milling of dovetail tenons and box joints. |

| Simple operator station just to the side of the work area for quick access. |

| Electrical components are UL & CE approved and neatly arranged in a dust-proof cabinet. |

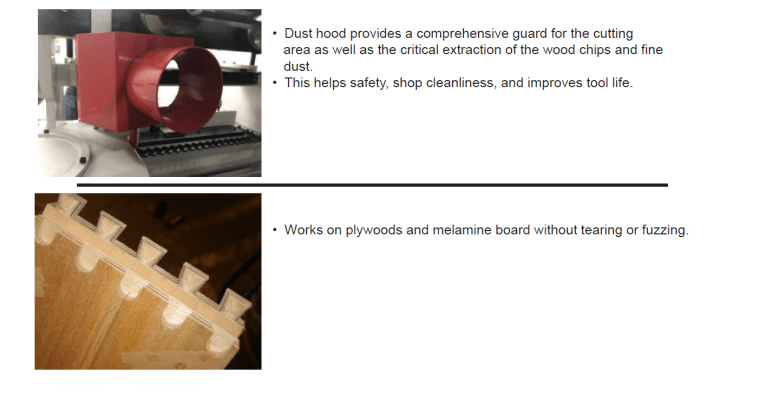

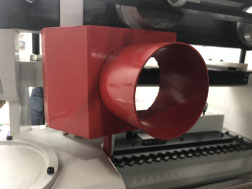

| Dust shroud provides a comprehensive guard for the cutting area as well as the critical extraction of the wood chips and fine dust. |

| Beneficial to safety, shop cleanliness, and improved tool life. |

| The new Diamond Series Dovetailer is perfectly suited for milling plywoods and melamine boards without tearing or fuzzing. |

Specifications:

| Thickness Of Material: | 7 ~ 60mm (5/16″ – 2.25″) |

| Height Of Tenon: | 6 ~ 18mm (1/4″ – 11/16″) |

| Depth Of Mortise: | 10 ~ 25mm (3/8″ – 1″) |

| Cutter Spindle Vertical Adjustment: | 30mm (1-1/8″) |

| Maximum Workpiece Size: | (L) 1500mm x (W) 480mm (59″ x 19″) |

| Workpiece Clamping Cylinders: | 4 pcs. |

| Spindle Speed: | 21 |

| Spindle Motor: | 2HP |

| Dust Hood Outlet: | 100mm (4″) |

| Machine Dimensions: | (L x W x H) 53″ x 34″ x 48″ |

| Packing Dimensions: | (L x W x H) 60″ x 40″ x 57″ |

| Net Weight: | 1257 lbs. |

| Gross Weight: | 1323 lbs. |