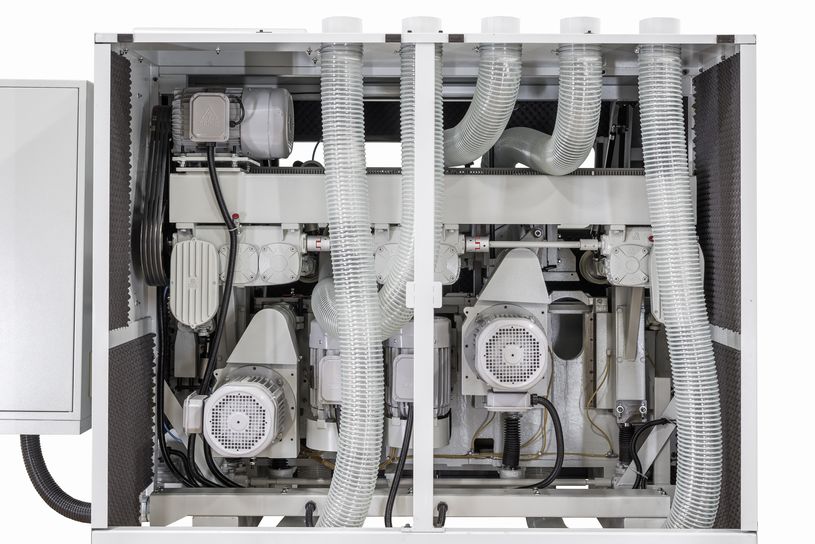

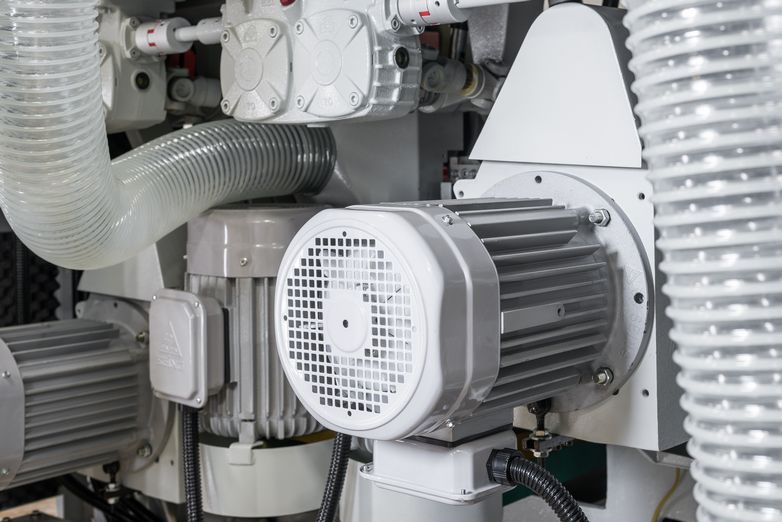

Spindle Arrangement

- 1st: Bottom horizontal: 7.5 HP, 6,000 RPM, 1-13/16″ spindle

- 2nd: Right vertical: 15 HP (Shared), 6,000 RPM, 1-13/16″ spindle

- 3rd: Left vertical: 15 HP (Shared), 6,000 RPM, 1-13/16″ spindle

- 4th: Top horizontal: 7.5 HP, 6,000 RPM, 1-13/16″ spindle

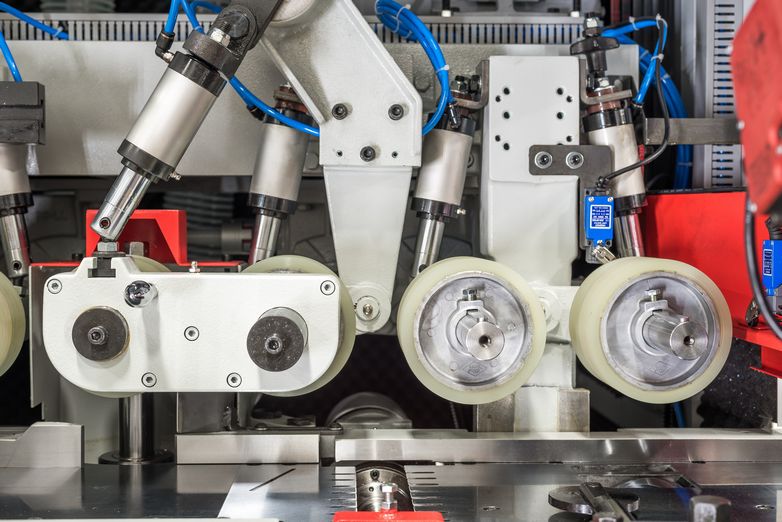

Feed System

- Feeding motor: 3 HP with inverter

- Elevation motor: 1/2 HP

- Feeding speed: 20 – 80 FPM

Product Dimensions

- Width: 10mm – 230mm (3/8″ – 9-1/2″)

- Thickness: 8mm – 170mm (5/16″ – 6-1/2″)

- Minimum length: 27″ Single-piece feed

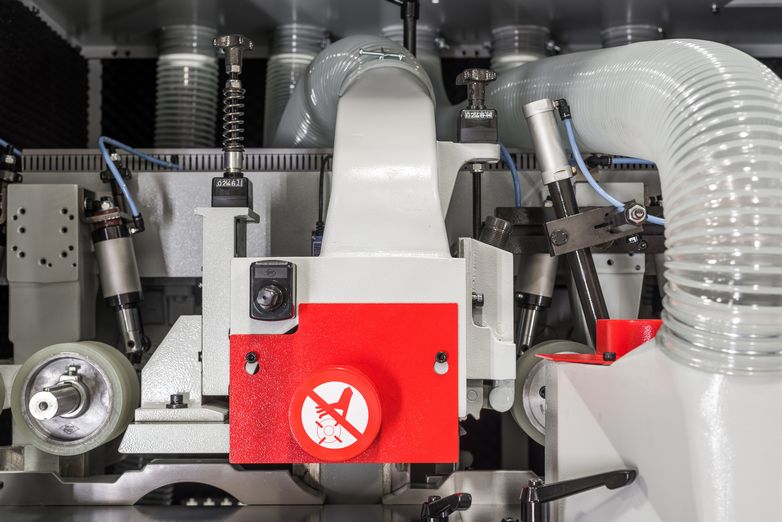

Features:

- Infeed table length: 60″

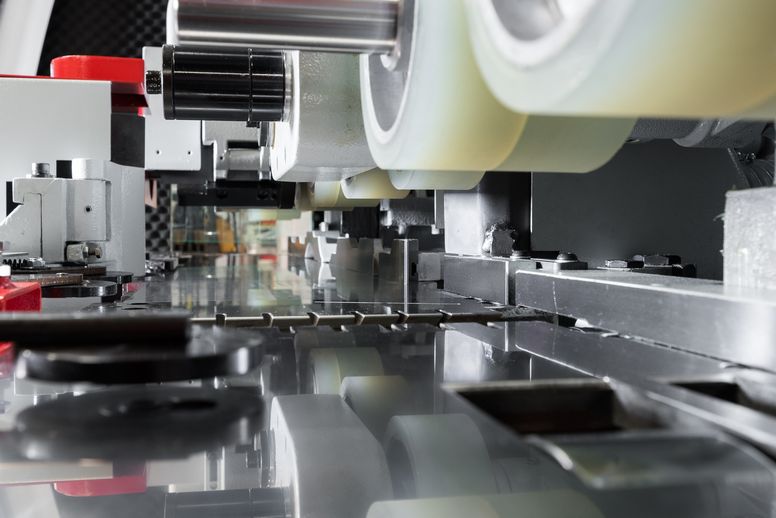

- The table is hard chrome plated

- (2) Powered bed rollers

- (1 set) Moulder heads (Included)

- Horizontal: (2) 5″ x 9″; 4 wing, 1-13/16″ heads

- Vertical: (2) 5″ x 4″; 4 wing, 1-13/16″ heads

- Dust collection: (5) 125mm (5″) dust ports requiring

- 681 CFM @ each point of extraction

- Gross weight: 7,380 lbs.

- Gross weight: 7,900 lbs.

- Machine dimensions: (L) 120″ x (W) 77″ x (H) 74″

- Packing dimensions: (L) 140″ x (W) 82″ x (H) 93″

- (1) Toolbox

- Warranty is one-year parts

- All machines are tested at the factory prior to shipment providing trouble-free start-up.

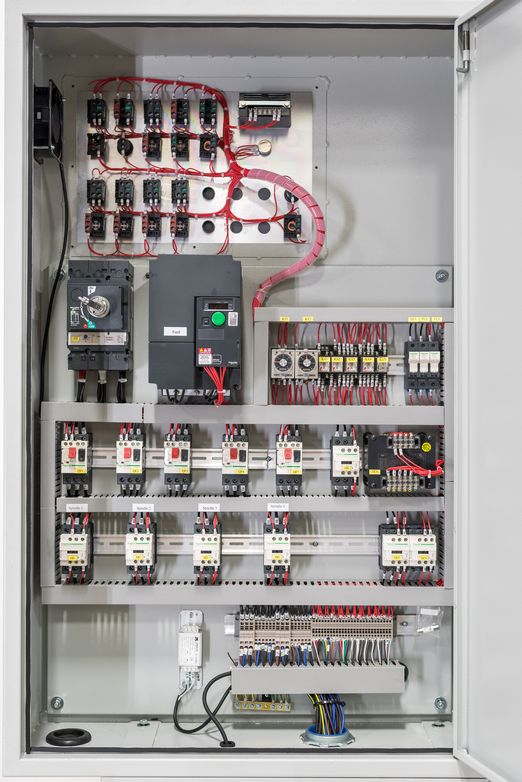

Specifications:

- Reverse Motor = Feed Motor

- Voltage/ Freq. = 230/460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 180/90 Amps

- Configuration = 4 Head

- Spindle Arrang. = Bottom Right Left Top

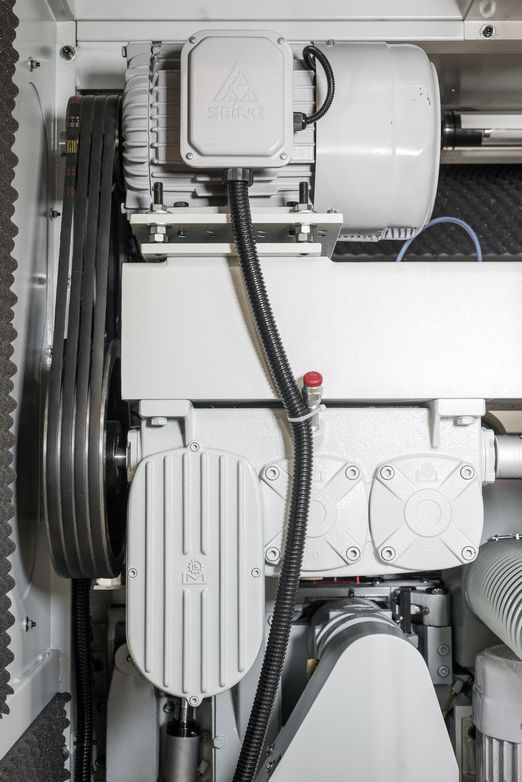

- 1st Spindle = 7.5 HP, 6,000RPM, 1-13/16″

- 2nd Spindle = 15 HP (Shared), 6,000RPM, 1-13/16″

- 3rd Spindle = 15 HP (Shared) , 6,000RPM, 1-13/16″

- 4th Spindle = 7.5 HP, 6,000RPM, 1-13/16″

- Spindle Diam. = 1-13/16”

- Spindle RPM = 6000 Rpm

- Under Nut Cap. = Horiz. 9-7/8” Vert. 7”

- Feed Hp. = 7.5 Hp.

- Feed System = Synchronized gearbox feed sys

- Drive System = Inverter controlled 7.5HP feed

- Feed Speed = 30 – 120 FPM

- Variable Speed = Inverter Controlled

- Reverse Feed = Yes

- Elevation Hp. = 1/2 Hp.

- Elevation Style = Up/Down Switch

- Elevation Sys. = Jack Screw / Gib System

- Total Hp. = 43 Hp.

- Electronics = UL Approved Components

- Dual Voltage = 208/300 Volt

- Control Voltage = 110 Volt

- Pass-Line = 35”

- Min. Length = 27” Single Piece

- Min. Width = 3/8”

- Max. Width = 9-1/2”

- Min. Thickness = 3/8”

- Max. Thickness = 6-1/2”

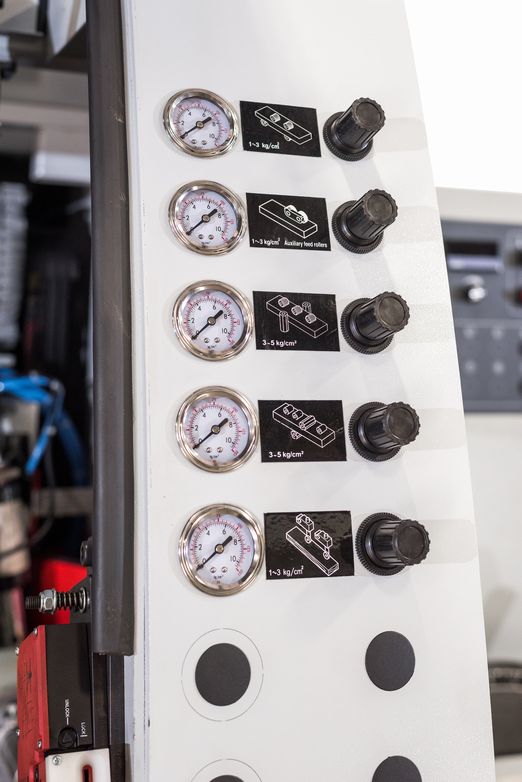

- Roller Type = Steel / Rubber

- Dust Collection = (5) 5” @ 3405 CFM Total

- Digital Display = Feed

- Powered Rollers = (12) 2” x 5-5/8”

- Idle Rollers = (2) 1” x 5-5/8”

- Pressure Shoes = (1) 7-1/8” X 8-3/4”

- Hold Down Style = Pressure Shoes/Rubber Rollers

- Emergency Stop = (2) Push Button

- Guarding = Full Cabinet Enclosure

- Grease Manifold = Remote Grease Manifold

- Oiler = Auto Oiler

- Fence Type = Adjustable Fence

- Fence Dims. = 1” x 60”

- Frame Const. = Cast/Steel Construction

- Worktable Dims. = 10-3/4” x 117”

- Chrome Bed = .004” Chrome Plated Bed

- Noise Bed Fing. = Noise Reduction

- Measure Meth. = Siko Counter

- Decible Rating = 64 dB

- Net Weight = 7380 Lbs.

- Gross Weight = 7880 Lbs.

- Machine Dims. = 120” x 82” x 92-1/2”

- Packaging Dims = 140” x 82” x 92-1/2”