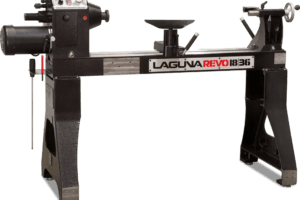

The 1216 controls the 1hp DC motor using pulse width modulation. A big problem with DC motor control is torque in the low speeds, and you will find many MIDI lathes with the lowest speed of 250RPM and higher because of this. This is because the cost effect controllers introduce resistance into the voltage to limit the power, which reduces the speed but also reduces the torque at the same rate. PWM will deliver full torque across the entire speed range. This allows for tremendous torque in low speeds which is helpful when roughing and precision work. This also allows for outboard turning up to a 16” bowl on a mid-sized lathe.

Electrical Requirements: 110V-1PH-60Hz

Recommended Breaker Size: 110V – 15 Amp

Speed Range High: 650 – 3500 RPM

Speed Range Mid: 325 – 1750 RPM

Speed Range Low: 50 – 525 RPM

Distance Between Centers: 15-½″

Swing Over Bed: 12-½″

Swing Over Banjo: 9-½″

Max Outboard Swing: 16″

Spindle Bore: ⅜″

Spindle Thread: 1″ x 8 TPI (Both Ends)

Front Bearing: 6006LLU

Rear Bearing: 6005LLU

Indexing: 24 Positions With Lock

Accepts Vacuum Chuck: No

Drive Belt: Poly-V Belt 6 Grooves

Tailstock Quill: MT #2

Tail Stock Quill Travel: 2-½″

Bed Length: 29.4″

Bed Gap: 1-1/4″

Tool Rest Length: 6″

Tool Rest Post Diameter: 1″

Faceplate Diameter: 3″

Certification: CSA C/US 256540

Floor To Bed Height: 6-3/4″ No Pads

Floor To Spindle Center: 13″ No Pads

Overall Size (L x W X H): 35.8″ x 14.6″ x 20.5″

Net Weight: 118 lbs

Shipping Weight: 125 lbs

Shipping Dimensions: 37″ x 15″ x 21″