Features:

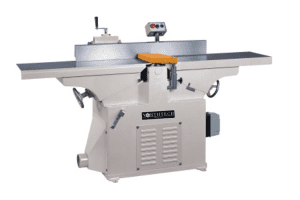

- Available machine width of 12″ or 16″.

- Bed way length is standard at 84″ on the 12″ model / 96″ on the 16″ model.

- The helical cutterhead is configured with six rows of 30 x 12 x 1.5 carbide 2-sided insert knives.

- Dynamically balanced cutter heads are precision fitted with class 5 NSK sealed bearings.

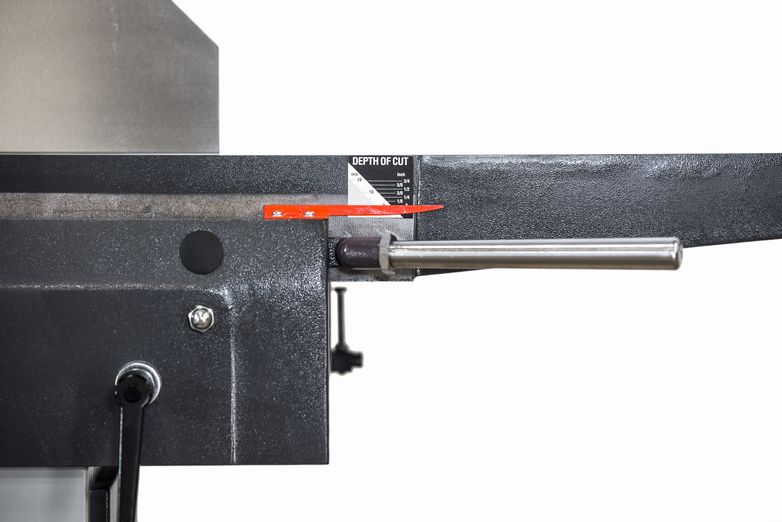

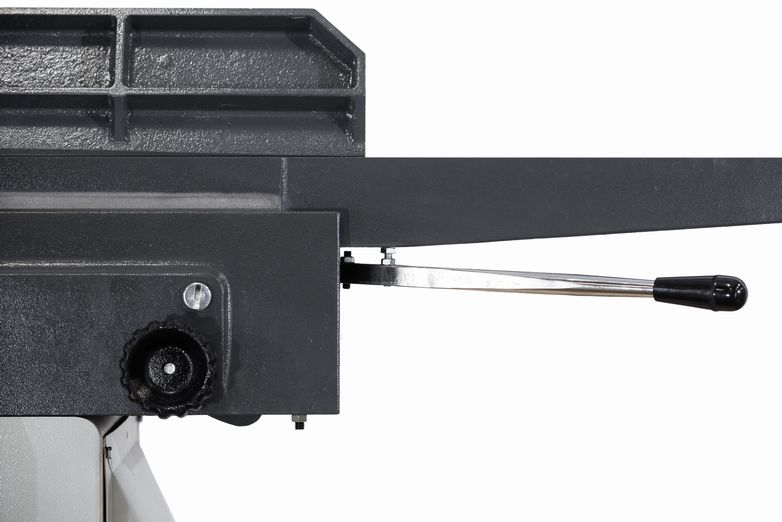

- Parallelogram-designed bed ways provide quick and accurate adjustment of infeed/outfeed beds vs. older style jack screw and handwheel system via cam and lever action. * Parallelogram design also facilitates the infeed table being in close proximity to the cutterhead, ensuring vibration-free cutting and excellent chip removal characteristics via the cam and lever handle.

- Machine bed ways are heat-treated, precision ground, and highly polished for incredible end-to-end and side-to-fence tolerances.

- The Center mount fence system employs a rack and pinion movement for quick and accurate positioning.

- Noise abatement fingers are precision ground on table edges surrounding cutter heads, improving sound decibel levels by over 25%.

- Motors are started and protected via magnetic controls with overloads / on-off control is remote and located above the infeed table.

- The oversized guard is standard, providing optimum operator protection (spring-loaded and adjustable tensioning).

- Weight on 16″ model . . . 956 lbs.

- Warranty is one-year parts

- All machines are tested stateside before shipment to ensure trouble-free start-up.

Specifications:

- Voltage/ Freq. = 230/460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 22/11 Amps

- Total Hp. = 7.5 Hp.

- Electronics = UL Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 220V Control Voltage

- Pass-Line = 31-1/2”

- Min. Width = 3” With Push Block

- Max. Width = 16”

- Cutter Head RPM = 5000 RPM

- Head Type = Dynamically Balanced Helical Head

- Cutter Head Dim = 4” x 16”

- Cut Head Matl. = Alloy Steel

- Rows of Cutters = 6 Rows

- No. of Inserts = 57 Inserts

- Insert Size = 30 x 12 x 1.5 mm

- Dust Collection = (1) 6” @ 981 CFM

- Guarding = Swivel Guard

- Fence Dims. = 5-3/8” x 47”

- Frame Const. = Cast Construction

- Infeed Table = 47-1/2”

- Outfeed Table = 47-1/2”

- Decible Rating = 73 Db

- Net Weight = 956 Lbs.

- Gross Weight = 1160 Lbs.

- Machine Dims. = 97” x 46” x 44”

- Packaging Dims = 100” x 30” x 40”