Mechanical:

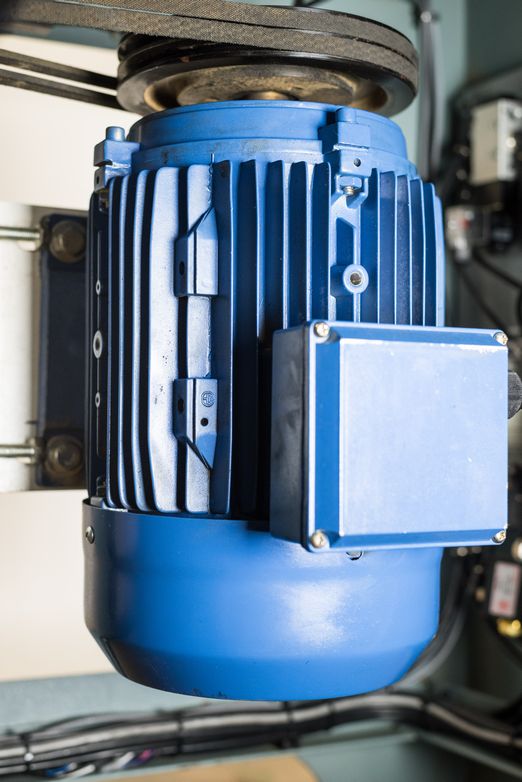

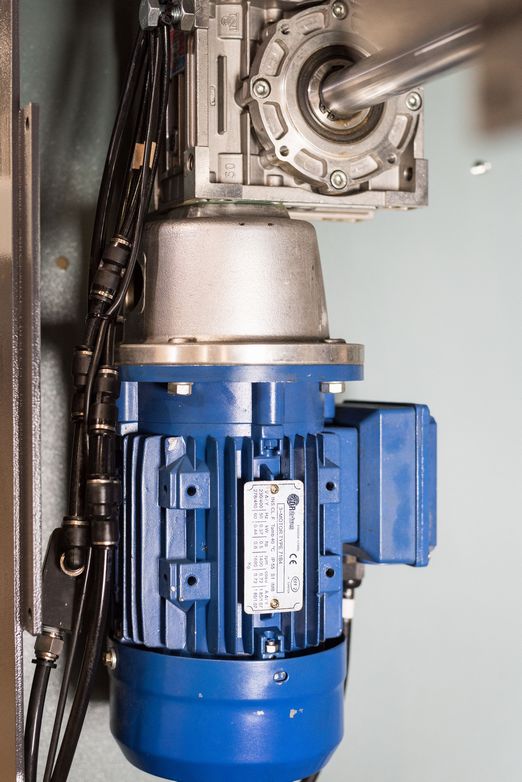

- Dual 5HP spindle motors 230, 3PH, 60 HZ

- 12 CFM @ 90 PSI required

- (1) 6” dust ports requiring 981 CFM @ point of extraction

Product Information:

- Width: 1-1/2” – 10”

- Thickness: 3/8” – 1-3/8”

- Length: 11” – unlimited

- Maximum Weight of Lumber: 32lbs

Features:

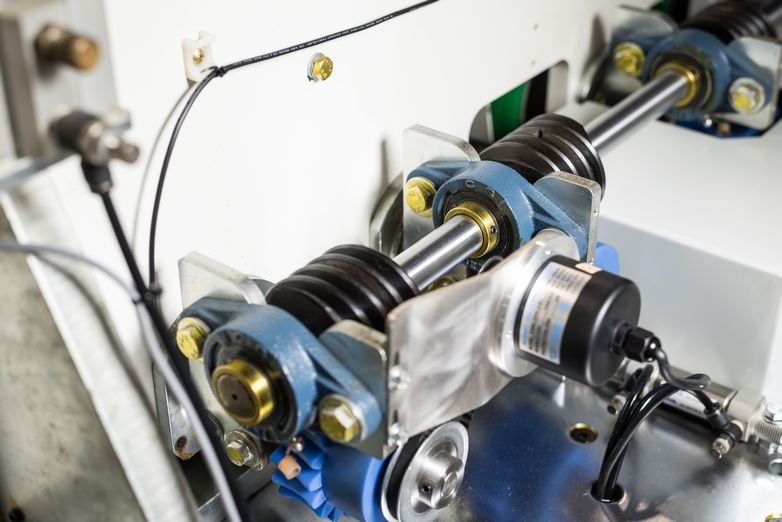

- 40mm spindles inside precision bearing

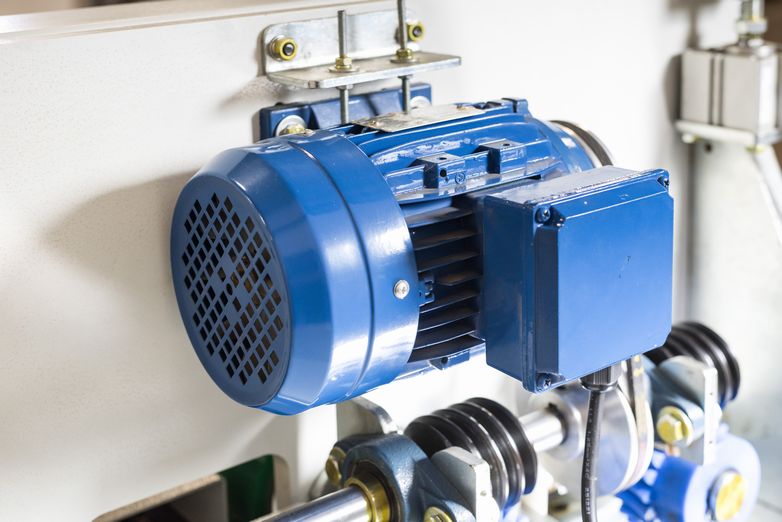

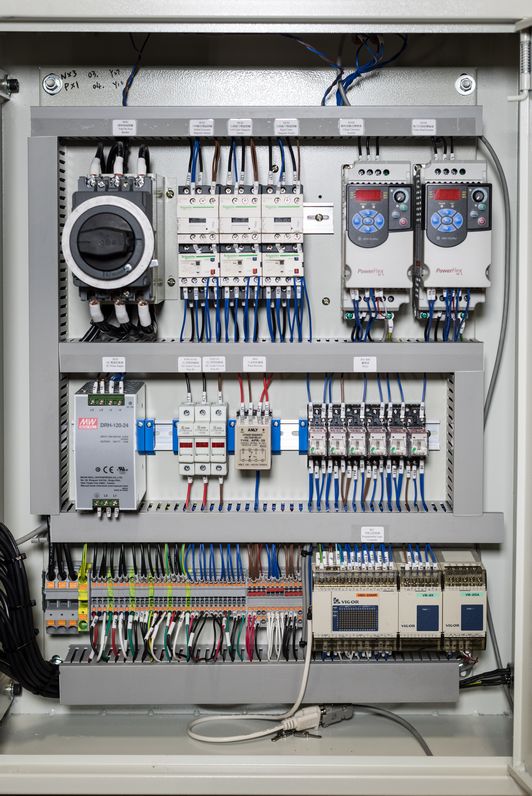

- 1HP PLC controlled feed system manages spindles position, part location and both infeed and outfeed hold downs

- Feed Speed: 80 – 400 FPM

- Pancake style T & G head, utilize carbide insert replacements for exacting repeatability (Included)

- Dual linear shaft guides for head movement

- Touchscreen interface with production tracking

- Chrome-plated table

- 134” Powered infeed and 88” outfeed

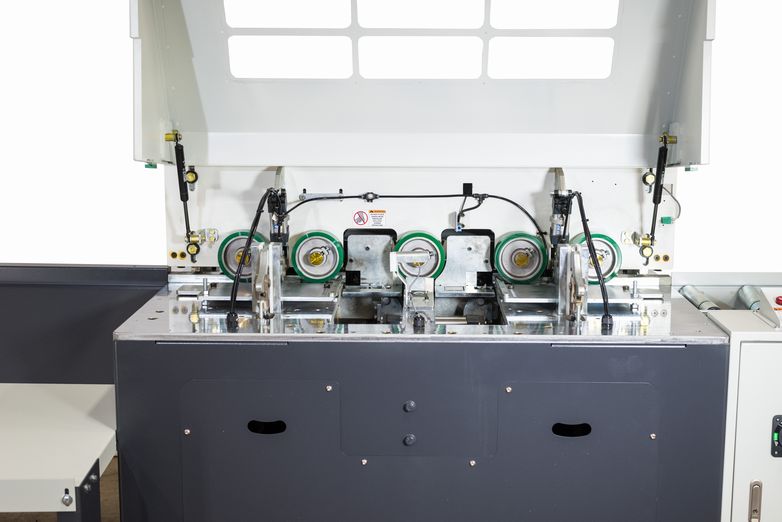

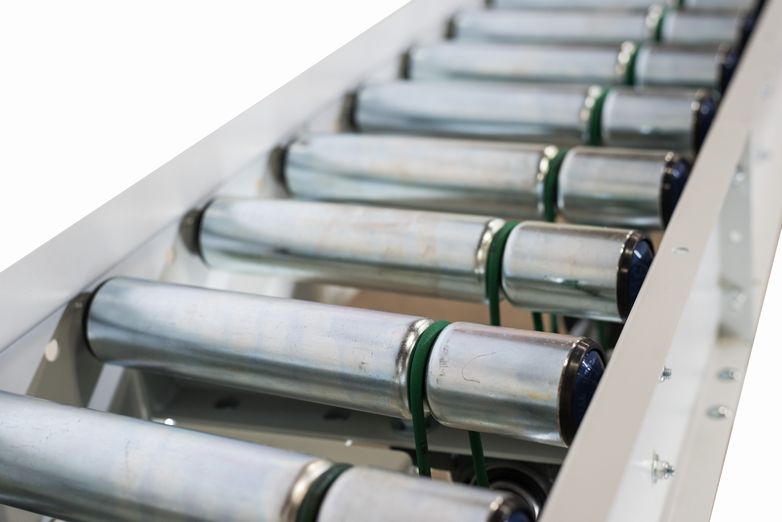

- Infeed and outfeed with dual action clamping system with (5) powered urethane rollers

- (3) Spring loaded bed rollers

- FLR included

- Fully automatic cycle operation

- Processing speed: 75’ / minute *Based on 6’ material length

- Net weight: 2,559 lbs.

- Machine dimensions without infeed / outfeed: (L) 72″ x (W) 33″ x (H) 55″

- Packing dimensions: (L) 78″ x (W) 39″ x (H) 63″

- (1) Toolbox

- Warranty is one-year parts

- All machines are tested stateside prior to shipment providing trouble-free start-up.

Specifications:

- Main Motor Hp. = 5 hp. x 2

- Machine Hp. = 12.5 hp.

- Voltage/ Freq. = 230 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 39 Amps

- Configuration = Toungue

- Spindle Arrang. = Groove

- 1st Spindle = 40mm 7400 Rpm Toungue

- 2nd Spindle = 40mm 7400 Rpm Groove

- Spindle Length = 5”

- Spindle Diam. = 40 mm

- Spindle RPM = 7400 Rpm

- Under Nut Cap. = 4-1/4”

- Feed Hp. = 1 Hp.

- Feed System = (5) 5-1/2” Poly Wheels

- Drive System = Gear Driven

- Feed Speed = 80 – 400 FPM

- Variable Speed = Programmable Feed Speed

- Elevation Style = Pneumatic

- Elevation Sys. = Pneumatic Cylinders

- Total Hp. = 12.5 Hp.

- Electronics = CE Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 24 Volt Control Voltage

- Programmable = Feed/Head Speed

- Touch Screen = 5-1/2” Touch Screen

- Pass-Line = 35-3/4”

- Min. Length = 10.63”

- Min. Width = 1-1/2”

- Max. Width = 10”

- Min. Thickness = .393”

- Max. Thickness = 1.375”

- Tooling = Tongue/Groove Insert Head

- Rows of Cutters = 8 Rows

- No. of Inserts = 48 Total Inserts

- Roller Type = 5-1/2” Poly Rollers

- Dust Collection = (1) 6” @ 981 CFM

- Dust Port Out = (1) 6”

- Cycles/Minute = 78 FPM on 6′ Material

- Conveyor = Powered Infeed Conveyor

- Powered Rollers = (5) 5-1/2” Powered Rollers

- Idle Rollers = (3) Idle Bed Rollers

- Hold Down Style = Pneumatic Rollers

- Total Clamps = (2) Clamps

- FLR Included = Filter, Lubricator, Regulator

- Recommended CFM = 3/8” Supply Line @ 90 Psi

- Emergency Stop = Push Button

- Guarding = Full Cabinet Enclosure

- Operation Style = Touch Screen Control

- Fence Type = Fixed Fence

- Frame Const. = 3/16” Steel Construction

- Worktable Dims. = 23-1/2” x 55-1/4”

- Table Const. = Steel

- Infeed Table = 133-1/2” Infeed

- Outfeed Table = 87-1/2” Outfeed

- Chrome Bed = .004” Chrome Plated Bed

- Measure Meth. = Precision Encoder

- Auto Cycle = Yes

- Decible Rating = 76 dB

- Net Weight = 2559 Lbs.

- Gross Weight = 2734 Lbs.

- Machine Dims. = 292-1/2” x 33-1/2” x 62”

- Packaging Dims = 78” x 39” x 63”