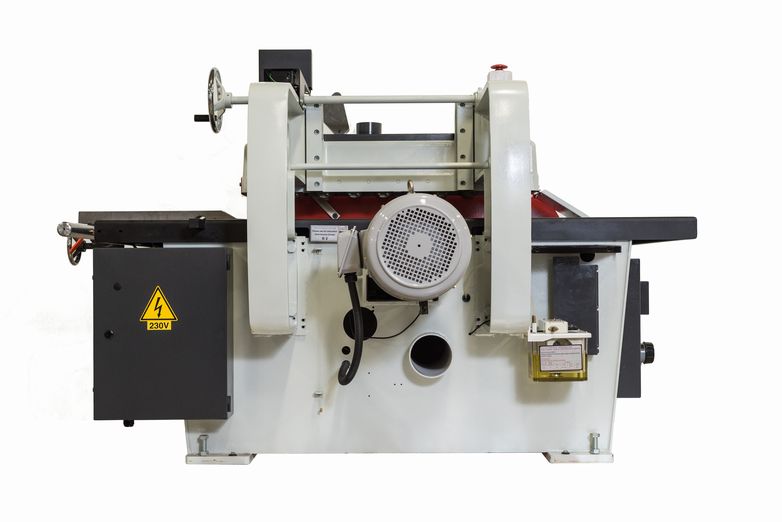

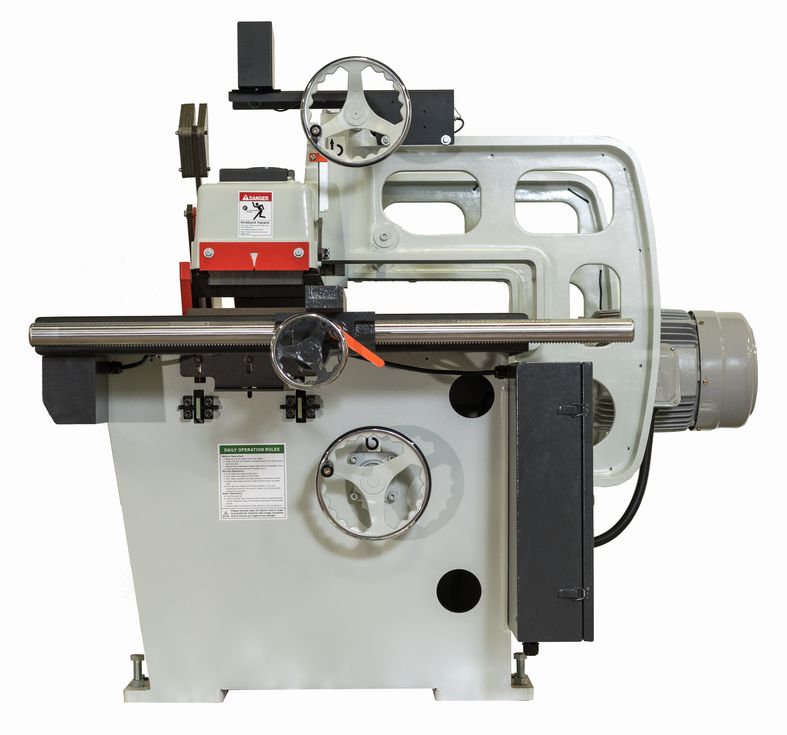

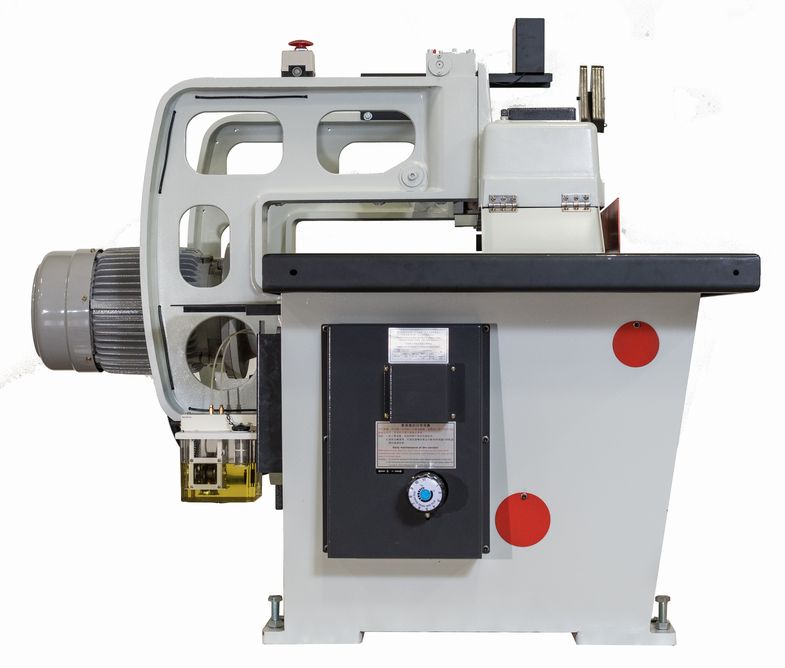

NT SLR-20SC PRECISION STRAIGHT LINE RIP SAW

FEED SYSTEM

- Saw motor: 25HP, 3PH 230/460V

- Feed: 3HP variable from 50′ – 190′ / minute

PRODUCT DIMENSIONS

- Min. thickness: 3/16″

- Max depth of cut: 5-15/16” with 20” Blade

- Max depth of cut: 4-15/16” with 18” Blade

- Max depth of cut: 3-15/16” with 16” Blade

- Max depth of cut: 2-15/16” with 14” Blade

- Max. width of stock: (Blade to column arms) 26-1/4″

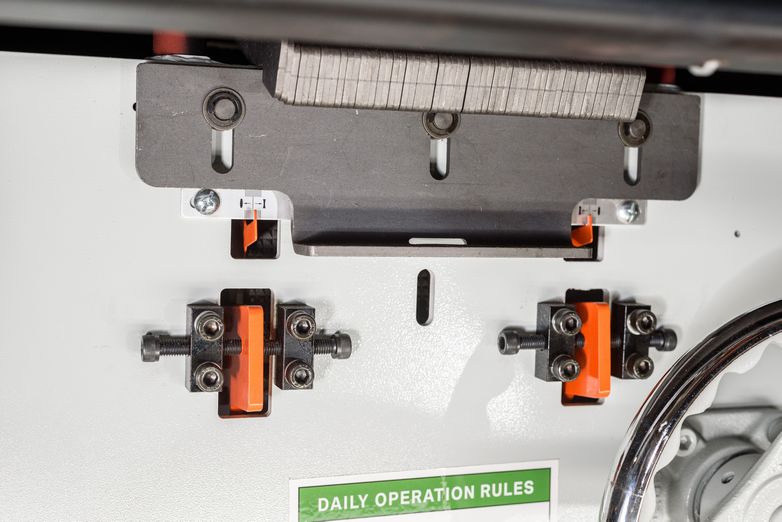

FEATURES

- Chain and Race equipped with “True Track”

- Table size 40″ x 83″

- Machine frame is constructed of a 1″ thick base plate

- Solid steel frame with 1″ thick column arms.

- Safety door switch with pneumatic motor brake.

- 2″ arbor and large support bearings.

- Glue line guarantee on 4/4 stock is 14′ – 16′ at 50 FPM.

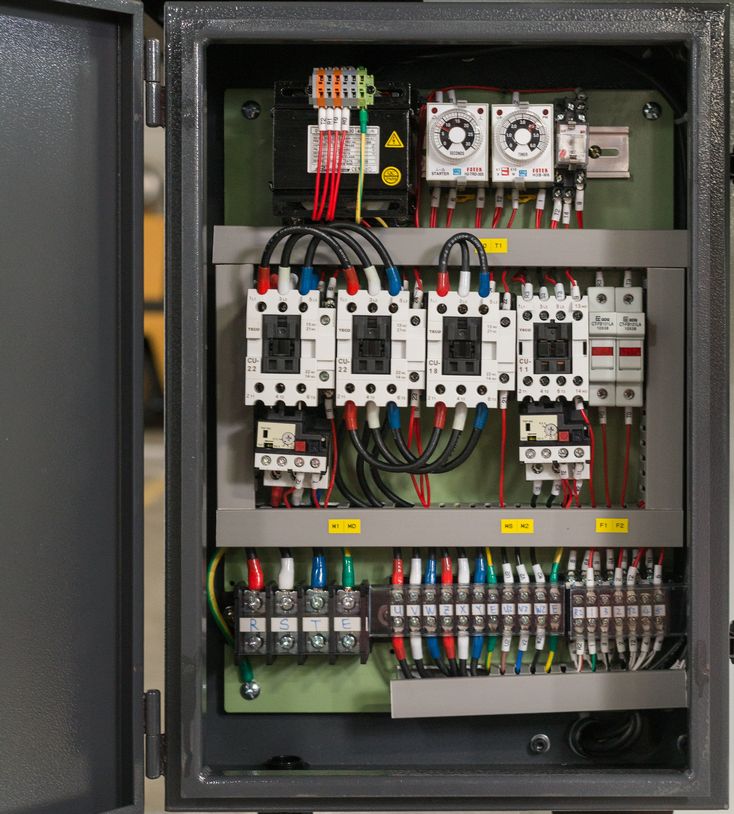

- All motors and electricals are UL rated.

- Industrial fence with cam lock quick release on rack and pinion glide.

- Two rows of heavy duty kickback fingers.

- (8) large pressure rollers for optimum glue line ripping.

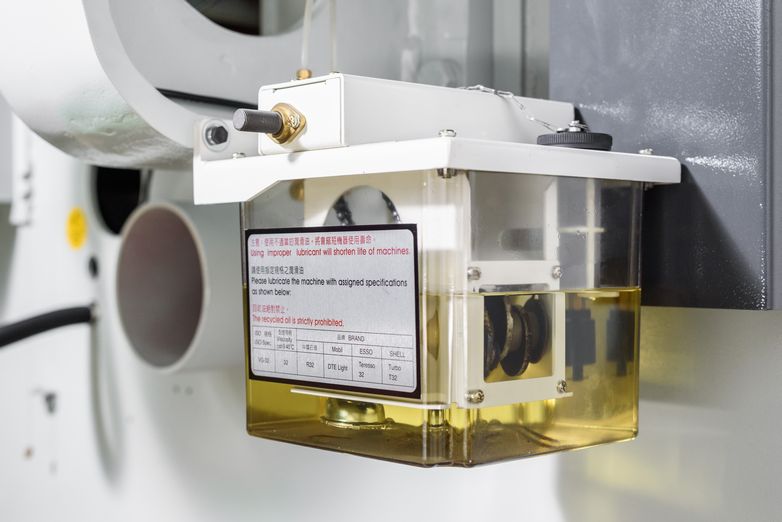

- An automatic mechanical oiling system with low oil level feed shutoff.

- A 100mw laser light and mounting bracket are included.

- (1) Tool box

- Amperage requirements: 25HP + 3HP 230V / 460V: 66A / 33A

- Dust collection requirements: (1) 4″ dust port requiring 450 CFM @ each point of extraction

(1) 6″ dust port requiring 981 CFM @ each point of extraction

- Weight: 4,090 lbs.

- Machine dimensions: (L) 92″ x (W) 67″ x (H) 60″

- Warranty is one-year parts

- All machines are tested stateside prior to shipment providing trouble-free start-up.

- Main Motor Hp. = 25 hp.

- Direct Drive = Direct Drive

- Voltage/ Freq. = 230/460 Volt 60Hz

- Phase = 3 Phase

- Amp Requirement = 66/33 Amps

- Feed Hp. = 3 Hp.

- Feed System = 4” Split Chain with True Trac

- Drive System = Belt

- Feed Speed = 50 – 190 FPM

- Variable Speed = Mechanical

- Elevation Style = Manual Wheel Adjustment

- Elevation Sys. = Linear Gauge with Hand Wheel

- Total Hp. = 28 Hp.

- Electronics = UL Approved Components

- Dual Voltage = 230/460 Volt

- Control Voltage = 110 Volt

- Assisted Start = Wye Delta

- Pass-Line = 32-3/4”

- Throat Capacity = 26-1/4”

- Min. Length = 18-1/4”

- Min. Width = 1”

- Min. Thickness = 3/16″

- Max. Thickness = 5-15/16” W/ 20” Blade

- Glue Line Rip = 14′ – 16′ 4/4 stock @ 50 FPM

- Arbor Rpm = 3540 Rpm

- Blade Size = 14” Tungsten Carbide Tipped

- No. of Teeth = 70 Tooth

- Tooth Spacing = 5/8 In.

- Blade Kerf = .197 In.

- Tracking Style = “True Track” System

- Tension Style = Gravity

- Vertical Travel = 3/16” – 5-3/4”

- Dust Collection = 4” Top 6” Bottom 1417 Total

- Dust Port Out = 4” Top 6” Bottom

- Arbor Diameter = 2″ Arbor

- Chain Adj. = True Track Adjustable Chain

- Idle Rollers = (8) Idle Rollers

- Hold Down Style = 8 Spring Loaded Hold Downs

- Kickback Finger = 86 Bottom / 34 Top Kickback Fi

- Recommended CFM = 1417 Total CFM

- Emergency Stop = Push Button

- Rear E Stop = Push Button

- Safety Feature = Door Switch / Motor Brake

- Guarding = High Visibility Guarding

- Oiler = Automatic Mechanical Oiler

- Low Oil Warning = Low Oil Shut-off

- Fence Type = Industrial Cam Lock Quick Rel

- Fence Dims. = 2” x 26-7/8”

- Brake System = Air Brake on Motor

- Frame Const. = 1″ Base 1/2″ Cabinet 3/4″ Arms

- Worktable Dims. = 40” x 83” x 33-1/2”

- Table Const. = Steel

- Laser = 100mw Laser Light & Mount Bracket

- Decible Rating = 82 dB

- Net Weight = 3872 Lbs.

- Gross Weight = 4090 Lbs.

- Machine Dims. = 92” x 67” x 60”

- Packaging Dims = 89” x 69” x 70”