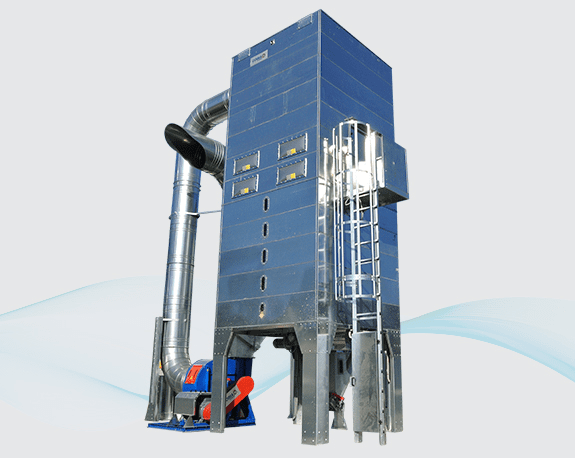

The MVD Mini-Silo Baghouse Dust Collector consists of two main sections:

- UPPER SECTION contains a filtering battery faired with galvanized modular panels housing (90) polyester filtering sleeves (standard version) fixed to a tube sheet by snap rings. The tube sheet separates filters from the clean air side, and is provided with a mechanical shaker cleaning system.The filter housing output is flanged for connecting to the negative pressure fan duct or exhaust/return air duct, has explosion vents on one side of the filtering area and access doors to the filters and cleaning system located on top. Positive pressure system configurations are available upon request.The collector features a ladder and walkway with a security device to prevent unauthorized access. The MVD Mini-Silo is also provided with a water extinguishment system composed of sprinklers inside the filter unit and external galvanized pipe to be connected to the fire sprinkler water supply.The supply-side ducting includes a settling chamber with baffle which prevents damage to the filtering sleeves by reducing particulate velocity. Expansion of the silo requires additional height clearance as this accommodates longer filter sleeves (the number of filters does not change).

- LOWER SECTION is made of thick galvanized modular panels assembled with galvanized fasteners, adjustable support legs made of thick press-bent galvanized steel sheet, and a flat bottom to support the motorized waste extractor. The MVD Mini-Silo is also provided with a kit for unloading the collected waste material into a bag.An inspection door provides easy extractor maintenance, and Lexan windows allow visual inspection of the material within the silo, as well as one or more level indicators. The dirty air inlet is flanged for strong connections to the supply ductwork.The standard version includes the extractor and bag unloading. A rotary air lock discharge valve is available as an option, ideal for use with material transfer systems, briquette machines, or haul-away waste bins.

The MVD Series is suitable for operation in both positive and negative pressure applications.

Available models with capacity from 5,000 to 11,000 CFM.

Silo storage capacities from 7.8 to 15.7 cubic yards.

| MODEL | AIRFLOW (CFM) | STATIC PRESSURE | FAN (HP) | FILTER AREA | FILTER length | OVERALL HEIGHT | base sides |

|---|---|---|---|---|---|---|---|

| MVD-1 | 3,650 | 11″ | 20 HP | 765 ft2 | 49″ | 193″ | 123″ X 123″ |

| MVD-2 | 8,850 | 13.8″ | 30 HP | 1185 ft2 | 76″ | 212″ | |

| MVD-3 | 11,750 | 13.4″ | 40 HP | 1680 ft2 | 108″ | 250″ | |

| MVD-4 | 3,650 | 11″ | 20 HP | 765 ft2 | 49″ | 212″ | |

| MVD-5 | 8,850 | 13.8″ | 30 HP | 1185 ft2 | 76″ | 231″ | |

| MVD-6 | 11,750 | 13.4″ | 40 HP | 1680 ft2 | 108″ | 270″ | |

| MVD-7 | 3,650 | 11″ | 20 HP | 765 ft2 | 49″ | 231″ | |

| MVD-8 | 8,850 | 13.8″ | 30 HP | 1185 ft2 | 76″ | 250″ | |

| MVD-9 | 11,750 | 13.4″ | 40 HP | 1680 ft2 | 108″ | 289″ |