Advantages over Hand Nesting

- Eliminates Repetitive Manual Labor

- Nesting Bundles by Hand is a Labor Intensive Job that the Auto-Nester can Solve, reducing employees exposure to repetitive motion

- Improves Yield and Increases Margins

- Hand nesters tend to oversize bundles, by as much as 3%. The Auto-Nester accurately measures the length of each and every board to know which sequence of boards will create the most accurate row

- It keeps track of all rows and is able to size rows as it nears the end of a bundle to create a bundle nested extremely close to the target square footage

- Consistent Bundles

- The Auto-Nester will build bundles that not only are more consistent mathematically, they also look more consistent. This will create the perception of a higher quality bundle

- Quality Control of Bundles

- Tracks Items such as average board length, number of shorts, and bundle square footage, which can all be controlled and adjusted by the software

- Software alerts the operators of short rows or bundles so the quality of the bundles can be managed bundle by bundle instead of by a random sampling

- Software Accurately Tracks all Incoming and Outgoing Data for Production Reports

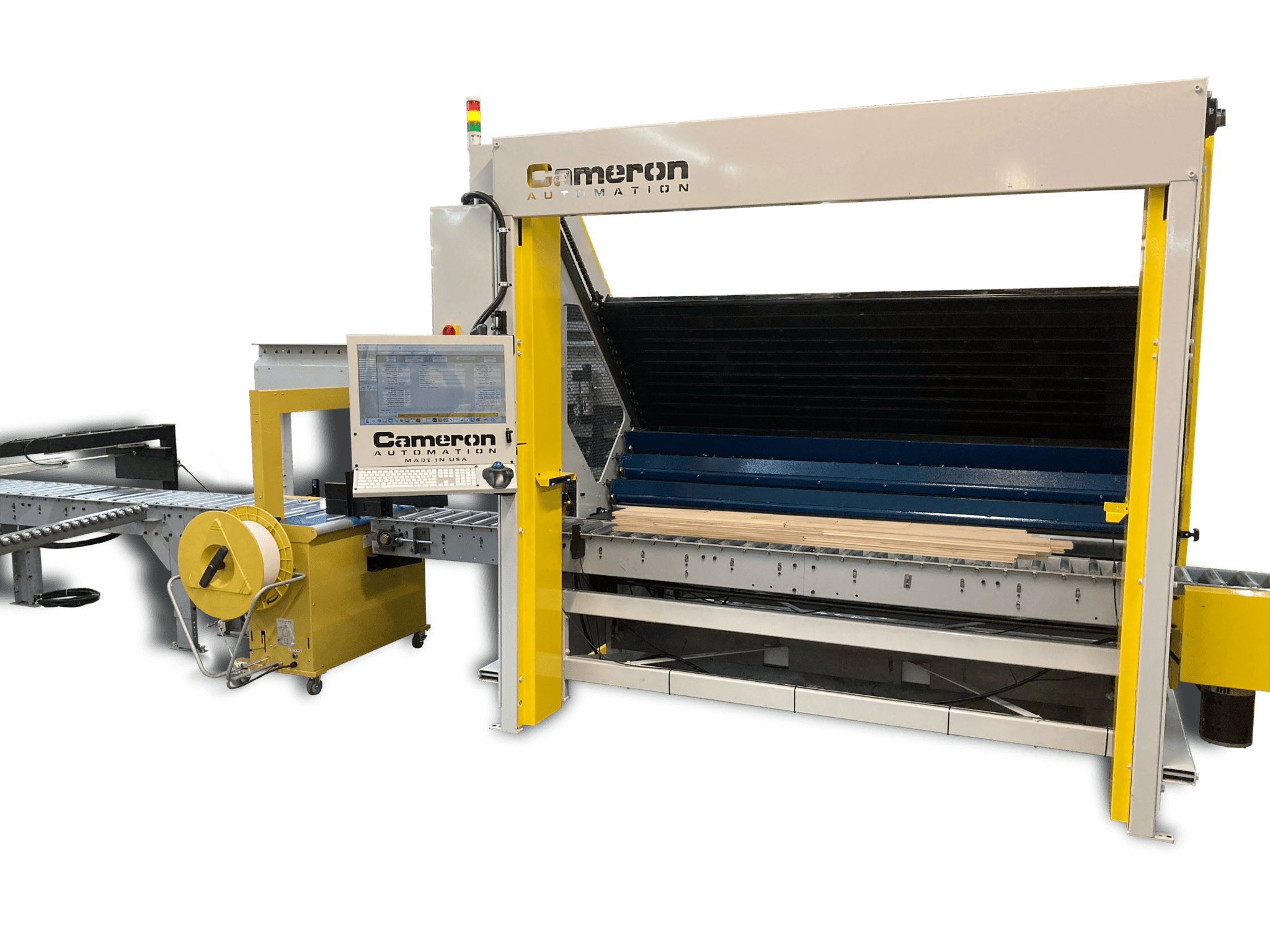

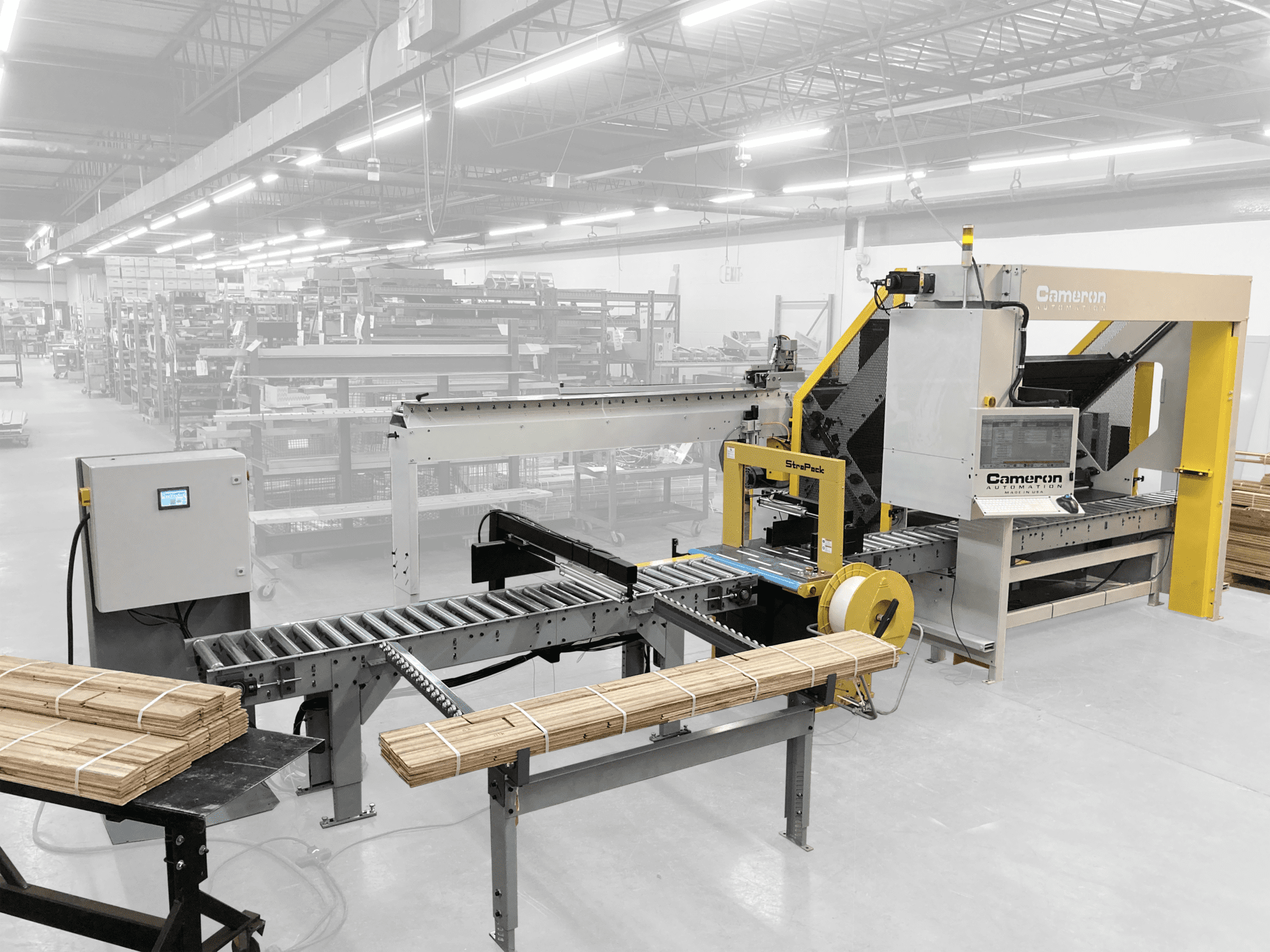

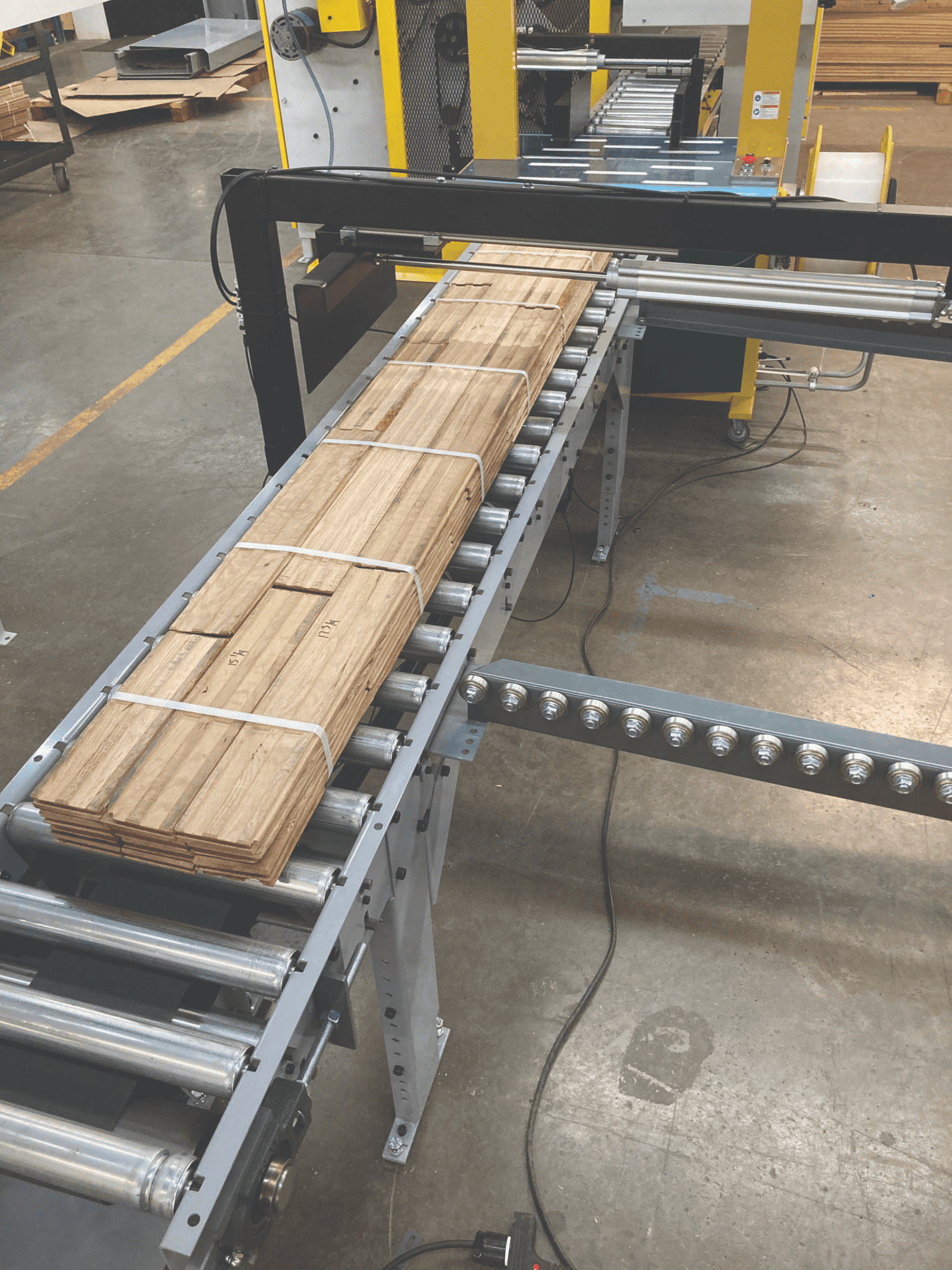

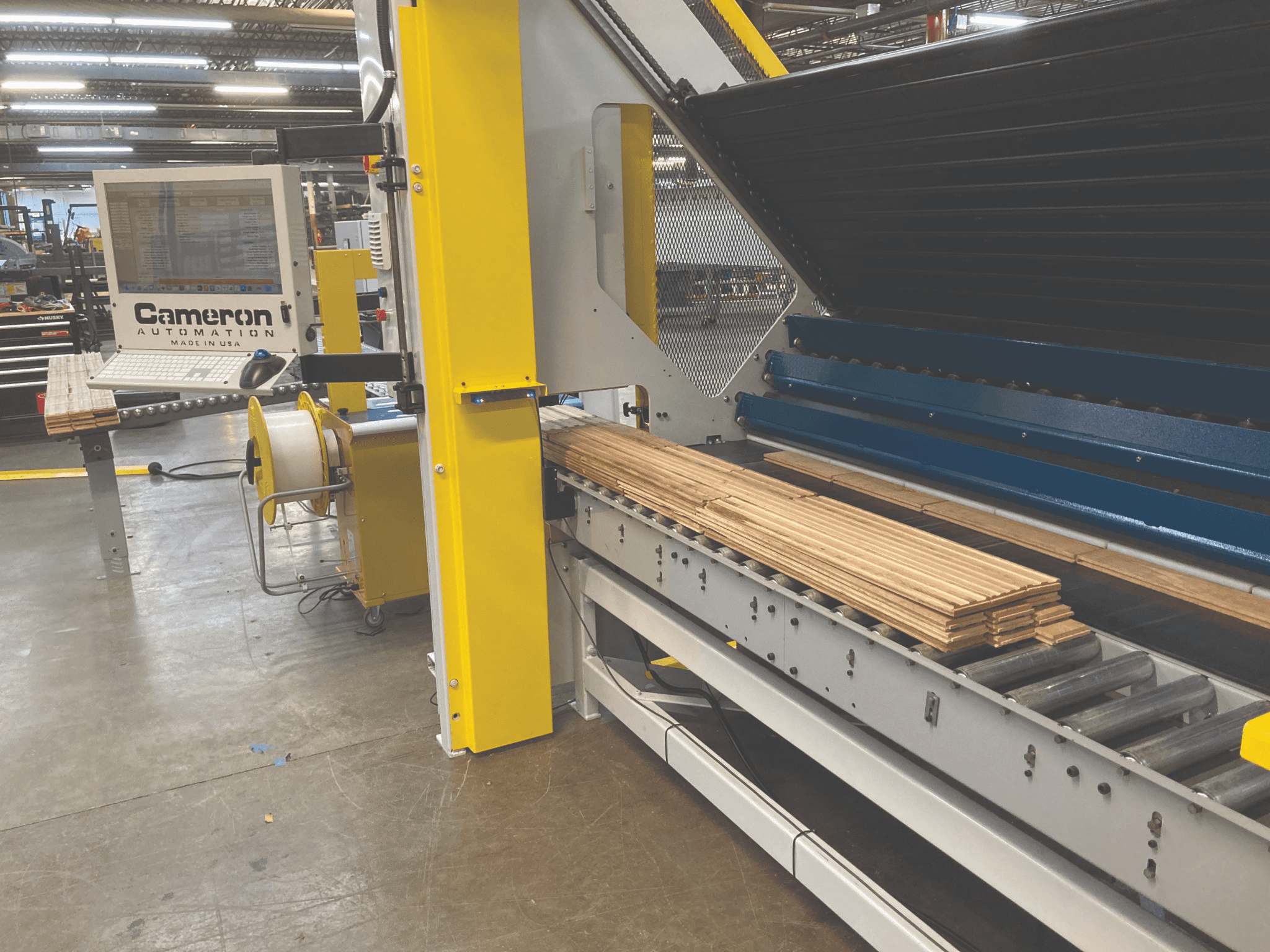

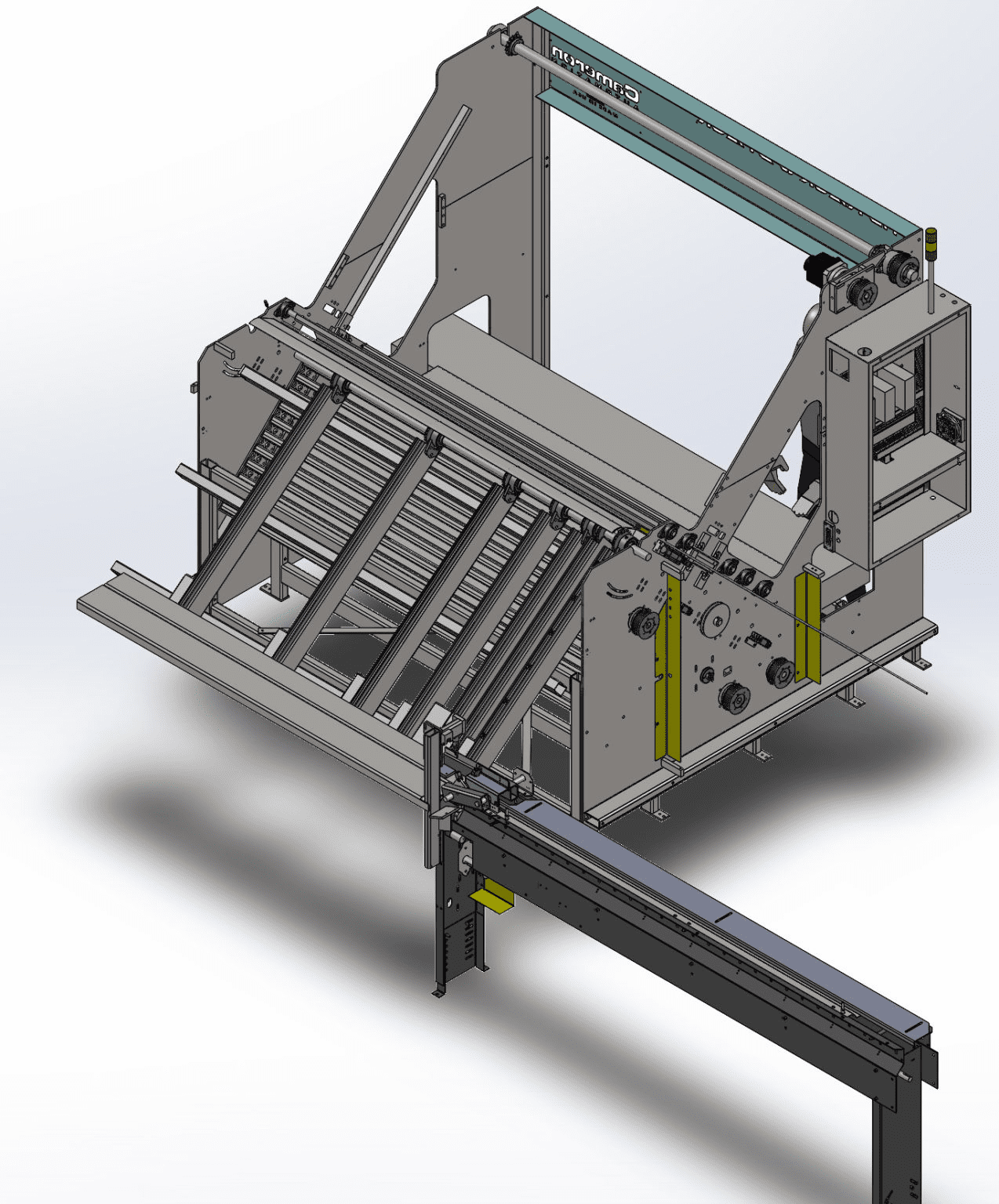

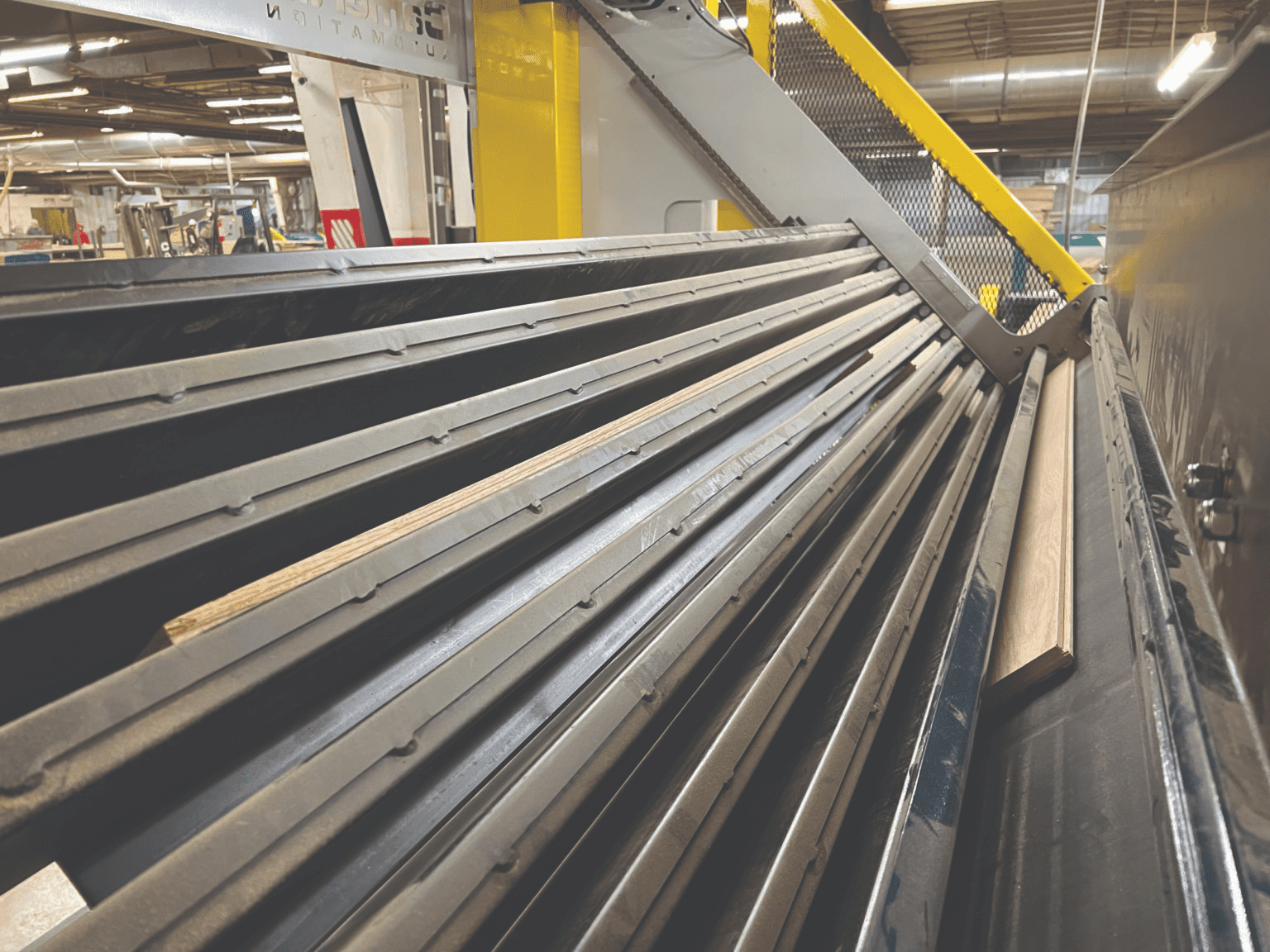

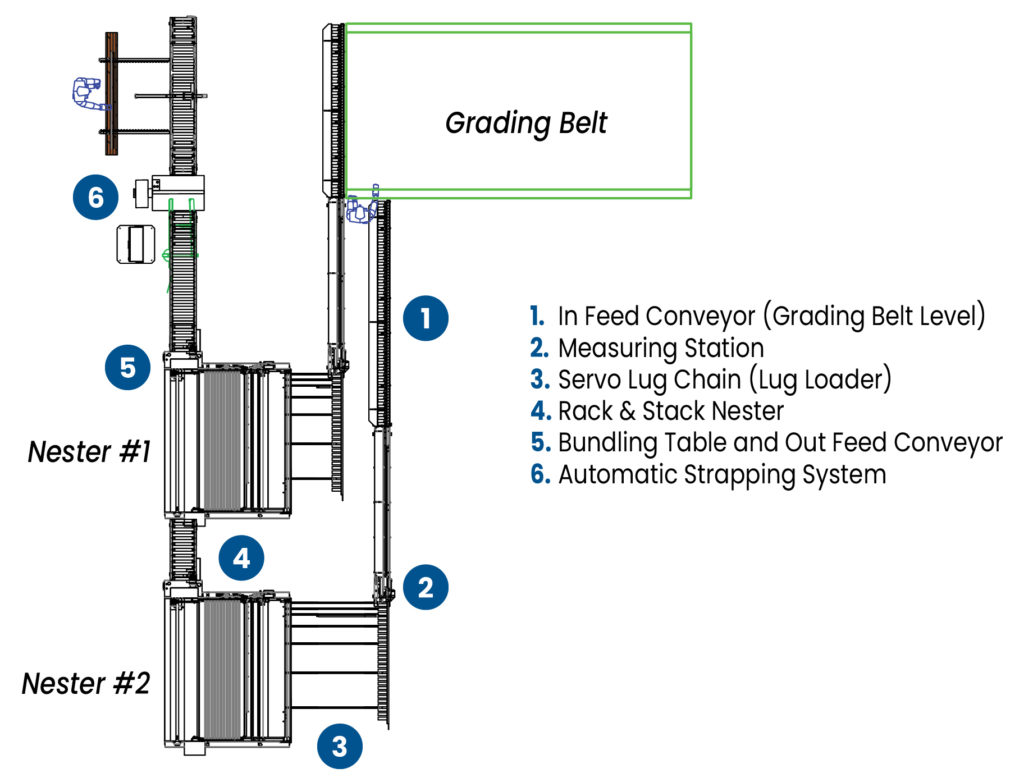

Flooring strips of random length enter the machine where they are measured for length. Strips are released by two sets of stops onto the main conveyor. At precisely the right time, a strip is scooped off of the main conveyor by an innovative lifting system. A computer processes the lengths of the strips to determine which combination of strips will produce an accurate length row. The machine constantly picks up and puts down strips to create rows. Rows are accumulated on the outfeed to create layers on the outfeed table. Layers are stripped off of the outfeed table to create bundles. Completed bundles are pushed off of the outfeed onto a conveyor, ready for strapping and packaging.