Specs:

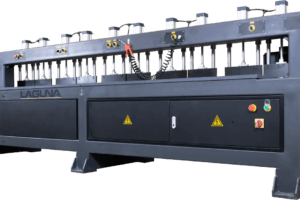

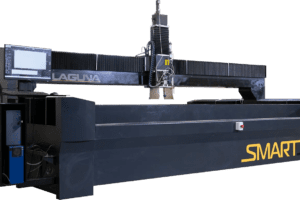

- Huge machining area 5′ X 16′ —1500mm x 4800mm *Custom sizes available

- Unique Pressure “Shoe” design for optimum depth accuracy- even if the panel is not completely flat

- Helical Rack and Pinon drives on X and Y axes. Ball screw on Z axes

- 1,2 and 3 spindle design. Also available with ATC spindle

- (3) 6HP Italian HSD spindles shown on machine below

- B&R Industrial Controller with Touch Screen Controls

- Planetary Gear Boxes on all 3 axes

- 6 Zone Vacuum Table

- (2) 10HP Vacuum Pumps

The “silky-smooth” movement of the traveling gantry machines is a result of precise machining of the frame components, precision-ground contour guide rails in all axes, and world-class motion control. Movement on both X and Y axes is achieved with helical rack-and-pinions driven by precision planetary drive systems. Z axis motion is controlled by precision-ground ball screw and the precision planetary drive system.

To complement this, Laguna Tools has also developed an exclusive ACM machining package that includes three “floating head” CNC electro-spindles to perform the machining functions that are typical to ACM fabrication. The floating head feature is beneficial to insure consistent miter fold depth across the entire surface of the ACM panel. The ACM machining package also includes a highly-efficient chip removal shroud system that directs all of the available vacuum to the active machining head, keeping chip damage to a minimum.

A typical Laguna Composite Fabricator CF16 configuration would include two machining heads used for miter-folding and panel cutout, respectively. The third floating head in the package also includes mist lubrication and is especially well-suited for machining the aluminum extrusions that are typically required in addition to panel fabrication.

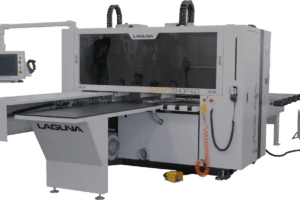

Finally, to complete the perfect ACM machining center, Laguna Tools included its Laguna “Touch” CNC fully-networkable machine controller that was developed in an exclusive partnership with Austrian machine control giant, B & R Automation. This touch screen-based control interface makes the Laguna CF16 both easy-to-learn and easy-to-use ensuring a quick learning curve by you or your employees.

Aluminum Composite Panel (ACP) or Aluminum Composite Material (ACM) is a widely-used term describing flat panels that consist of a non-aluminum core bonded between two aluminum sheets. Aluminum sheets can be coated with PVDF or Polyester paint. ACPs are frequently used for external cladding of buildings (building facades), for insulation and for signage.